Table of contents

Top 10 Film Faced Plywood Manufacturers in Vietnam 2025

🌍 Introduction & Overview

Global Demand for Film Faced Plywood

The global construction industry in 2025 continues to rely heavily on film faced plywood. This material is vital for concrete formwork, scaffolding, flooring, bridges, and infrastructure projects. Worldwide demand has increased due to rising investments in Asia, the Middle East, and Africa.

Contractors and importers are actively searching for the top 10 film faced plywood manufacturers in Vietnam 2025 because Vietnamese suppliers consistently deliver cost-effective yet high-quality solutions.

International buyers need panels that can be reused multiple times, withstand water immersion, and resist harsh weather. Vietnamese factories have optimized production with phenolic WBP glue, eucalyptus or acacia cores, and film GSM ranging from 120 to 220.

As a result, Vietnam has become the preferred destination for film faced plywood suppliers and exporters worldwide.

Why Importers Search for Vietnam Plywood

The phrase “top 10 film faced plywood manufacturers in Vietnam 2025” is not just a search term—it reflects purchasing intent.

As a result, Vietnam has become the preferred destination for film faced plywood suppliers and exporters worldwide.

What This Article Covers

- Profiles of the top 10 plywood manufacturers in Vietnam 2025

- Technical specifications (thickness, film GSM, core types, glue)

- Certifications for major markets (India, EU, USA, GCC)

- Pricing insights and 2025 market forecasts

- Importing guide with HS codes, Incoterms, and container loading

- A practical checklist for verifying suppliers and exporters

👉 With this structure, Kadence will automatically detect the headings and generate a clear table of contents, making it easier for readers to navigate.

🇻🇳 Why Vietnam Leads the Market

Cost Advantages for Global Buyers

One of the strongest reasons buyers search for the top 10 film faced plywood manufacturers in Vietnam 2025 is price competitiveness. Vietnamese factories benefit from lower labor costs, abundant eucalyptus and acacia plantations, and efficient production systems.

Contractors and importers are actively searching for the top 10 film faced plywood manufacturers in Vietnam 2025.

This allows them to offer FOB prices that are typically 10–15% cheaper than China while maintaining reliable quality standards.

Importers in India, the Middle East, and Africa confirm that Vietnam consistently delivers a better price-to-performance ratio.

The reduced cost of raw materials and proximity to export ports such as Hai Phong and Ho Chi Minh further improve efficiency.

As a result, Vietnam film faced plywood suppliers can guarantee both affordability and consistency, which is crucial in large infrastructure projects.

By the end of this guide, you will have a clear roadmap of which factories to contact, what specifications to demand, and how to negotiate with confidence.

Export Capacity and Reliability

Vietnam’s plywood industry is not small-scale anymore. In 2025, the country is expected to export more than 5,000 containers of film faced plywood annually.

Leading companies such as HCPLY and other Vietnam film faced plywood exporters have established long-term partnerships with distributors in India, Saudi Arabia, Turkey, and Latin America.

This scale means buyers can secure both small trial shipments and large repeat orders.

Many manufacturers can load a 40HC container with 700–900 sheets depending on thickness, and still commit to short lead times of 20–25 days.

Such reliability is why importers searching for top film faced plywood manufacturers in Vietnam 2025 are confident in long-term supply agreements.

Compliance with International Standards

Another major advantage is Vietnam’s ability to meet compliance and certification requirements. Buyers from different regions demand different certificates:

- India: BIS certification

- Europe: CE and EUDR

- United States: CARB (California Air Resources Board)

- Global markets: FSC for sustainable forestry

Vietnamese manufacturers proactively align with these standards, which reduces the risk of customs delays and rejected shipments.

This proactive compliance gives Vietnam film faced plywood suppliers an edge over competitors in other regions.

Sustainable Growth and Global Trust

Beyond price and certificates, Vietnam has earned global trust. Importers report that Vietnamese exporters are transparent in communication, flexible with Incoterms, and willing to customize specifications. Sustainability is also becoming a core value, as many factories move toward FSC-certified production, eco-friendly glues, and reduced emissions.

👉 All of these factors explain why the top 10 film faced plywood manufacturers in Vietnam 2025 are positioned as the most reliable partners for international buyers, from small contractors to multinational distributors.

👉 All of these factors explain why the top 10 film faced plywood manufacturers in Vietnam 2025 are positioned as the most reliable partners for international buyers, from small contractors to multinational distributors.

🏆 Top 10 Film Faced Plywood Manufacturers in Vietnam 2025

When importers type top 10 film faced plywood manufacturers in Vietnam 2025, they expect more than just names—they want verified information, export capacity, certificates, and market credibility.

HCPLY – Vietnam Plywood HCPLY Co., Ltd

HCPLY is recognized globally as the leading manufacturer among the top 10 film faced plywood manufacturers in Vietnam 2025.

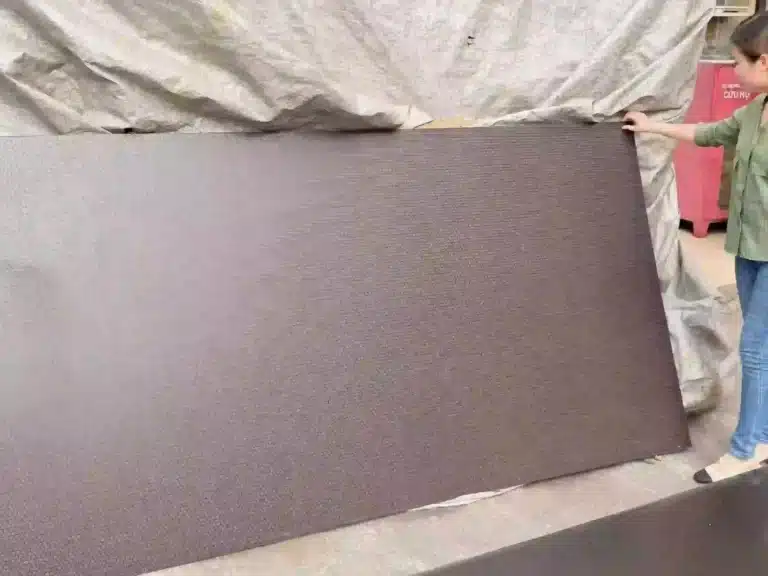

- Products: 9–21mm, WBP phenolic glue, brown/black/red film, GSM 120–220.

- Certificates: FSC, CE, EUDR, CARB.

- Strengths: Competitive FOB prices, fast lead times (20–25 days), and professional export support from dedicated staff such as Lucy and David.

👉 Importers consistently choose HCPLY because it combines scale, trust, and transparency.

Hung Chang Plywood (Phu Tho)

Hung Trang is a long-standing factory in Phu Tho province. Known for its eucalyptus core plywood, the company has built a reputation in India and the Philippines.

- Capacity: 50–80 containers per month.

- Focus: Film faced plywood for formwork, with BIS certification for the Indian market.

- Strength: Stable quality for re-use up to 10–15 cycles in concrete projects.

Importers recognize Hung Trang as one of the Vietnam film faced plywood suppliers best suited for infrastructure contractors.

Minh Thanh Wood (Bac Giang)

Minh Thanh specializes in poplar and combi core plywood. With modern hot-press lines and strict QC, it ensures consistent bonding and smooth film surfaces.

- Markets: Turkey, Egypt, and North Africa.

- Products: 12mm, 15mm, 18mm film faced plywood with phenolic glue.

- Certificates: FSC and CE available.

For buyers searching for Vietnam film faced plywood exporters, Minh Thanh is a trustworthy mid-sized manufacturer.

Phuong Anh Plywood (Phu Tho)

Phuong Anh is a family-owned factory that has grown into an exporter with stable capacity.

- Key Strengths: Customized sizes (1250×2500mm, 1300×2500mm) for lamination and niche projects.

- Markets: India, UAE, and Bangladesh.

- Export Reliability: Short lead time, transparent contracts, and strict thickness tolerance control.

This adaptability earns it a place among the top film faced plywood manufacturers in Vietnam 2025.

Thinh Long Plywood (Hanoi)

Thinh Long is known for supplying large distributors in India. The company’s strength lies in bulk exports and competitive pricing.

- Capacity: >100 containers/month.

- Markets: India and the Middle East.

- Focus: Durable plywood for scaffolding and heavy concrete formwork.

Buyers view Thinh Long as one of the most cost-effective Vietnam film faced plywood suppliers.

Junma Plywood (Binh Duong)

Junma is a joint venture with strong investment in modern machinery.

- Specialization: High-grade film faced plywood with phenolic resin for bridges and highways.

- Markets: Malaysia, Singapore, and GCC countries.

- Certificates: FSC, CE, and ISO.

Junma is ranked high among Vietnam film faced plywood exporters for demanding buyers who need guaranteed durability.

Tekcom Plywood (Hai Phong)

Tekcom has a reputation for premium plywood and international branding.

- Strength: Professional packaging, brand labeling, and private label options.

- Markets: Europe, Australia, and the USA.

- Products: Both film faced plywood and marine plywood.

Tekcom is considered one of the best plywood manufacturers in Vietnam for importers seeking high-end positioning.

Vinawood Group (Ho Chi Minh City)

Vinawood is one of the oldest plywood companies in Vietnam.

- Reputation: Known for stable supply chains and wide product range.

- Markets: Global—exports to over 30 countries.

- Certificates: FSC, CARB, CE.

Vinawood belongs to the top 10 film faced plywood manufacturers in Vietnam 2025 due to its global network and consistent brand recognition.

Dinh Huy Plywood Exporters

Dinh Huy focuses on cost-sensitive buyers.

- Strengths: Affordable film faced plywood without compromising core quality.

- Markets: Middle East, Africa, and South America.

- Export Support: Flexible payment terms (T/T, L/C) and small MOQ accepted.

Buyers appreciate Dinh Huy for being one of the Vietnam film faced plywood suppliers that cater to SMEs and smaller contractors.

Green Viet Wood

With a focus on competitive pricing and high-quality products, HCPLY continues to set the standard in the industry.

Green Viet emphasizes eco-friendly production.

- Focus: FSC-certified plywood, sustainable sourcing, and low-emission glues.

- Markets: Europe and North America.

- Certificates: FSC 100%, CE, EUDR.

Green Viet stands out among Vietnam film faced plywood exporters for buyers who prioritize sustainability.

👉 These ten companies form the backbone of the top 10 film faced plywood manufacturers in Vietnam 2025. Whether you need bulk supply for India, certified products for Europe, or branded solutions for global distribution, this list provides a verified starting point.

🌟 Spotlight: Why HCPLY is #1

Market Leadership

Among the top 10 film faced plywood manufacturers in Vietnam 2025, HCPLY – Vietnam Plywood HCPLY Co., Ltd clearly stands out. With more than 200,000 cubic meters of annual production capacity, HCPLY ships over 5,000 containers per year to India, the Middle East, Africa, Europe, and South America. This scale positions HCPLY as Vietnam’s most reliable plywood exporter.

The company is not only about volume; it is about long-term trust. HCPLY has maintained consistent partnerships with importers for more than a decade, proving its ability to adapt to changing regulations, fluctuating raw material costs, and evolving customer requirements.

Product Range and Technical Advantages

HCPLY offers a complete range of film faced plywood:

- Thickness: 9mm, 12mm, 15mm, 18mm, 21mm

- Core: Poplar, eucalyptus, acacia, or combi

- Film: Brown, black, red; GSM 120–220

- Glue: WBP phenolic, melamine, MR

This variety ensures HCPLY can meet the specific demands of importers in different markets. For example, Indian buyers prefer BIS-certified eucalyptus core plywood, while European clients demand EUDR and CE compliance. By offering multiple specifications under one roof, HCPLY simplifies sourcing for global customers.

Export Expertise

What sets HCPLY apart is its professional export support. Dedicated staff such as Lucy (Sales Manager) and David (Export Project Leader) provide 24/7 communication, detailed quotations, and flexible Incoterms (FOB Hai Phong / Ho Chi Minh, CIF/CFR to worldwide ports). Importers highlight HCPLY’s ability to optimize container loading—up to 900 sheets of 18mm film faced plywood in a 40HC—reducing logistics costs significantly.

Why Importers Trust HCPLY

- Verified certificates: FSC, CE, EUDR, CARB

- Consistent lead time: 20–25 days

- Transparent contracts with clear payment terms

- Competitive FOB and CIF pricing

- Responsive after-sales support

👉 For buyers searching for Vietnam film faced plywood suppliers or Vietnam film faced plywood exporters, HCPLY is not just a supplier—it is a strategic partner capable of supporting long-term growth.

⚖️ Vietnam vs China: Market Comparison

Price and Cost Efficiency

When comparing the top 10 film faced plywood manufacturers in Vietnam 2025 with Chinese factories, price is the first factor. Vietnam generally offers 10–15% lower FOB prices thanks to lower labor costs, local raw material availability, and efficient logistics. This makes Vietnamese plywood especially attractive for cost-sensitive markets such as India, Africa, and the Middle East.

Quality and Compliance

Vietnamese manufacturers focus on transparency and compliance. Buyers report that Vietnam film faced plywood suppliers deliver consistent thickness, smooth surface film, and higher reuse cycles (10–20 times in concrete formwork). Certificates such as FSC, CE, EUDR, BIS, and CARB are widely available, which reduces risk during customs inspections.

In contrast, some Chinese exporters face issues with mixed core plywood or delayed compliance with new regulations like EUDR, creating uncertainty for importers.

Lead Time and Logistics

Vietnam has a geographic advantage with faster shipping to South Asia and GCC markets. The average lead time is 20–25 days, while China often requires 30–40 days due to port congestion and longer sailing routes. This difference matters for importers managing tight project deadlines.

Transparency and Buyer Confidence

A key advantage of Vietnam film faced plywood exporters is transparent communication. Importers report clear documentation, proactive updates, and flexible solutions during negotiations. In contrast, buyers sometimes struggle with inconsistent communication and hidden charges when sourcing from certain Chinese factories.

Comparative Table: Vietnam vs China

| Criteria | Vietnam | China |

|---|---|---|

| 💵 Price | 10–15% cheaper | Higher labor & energy cost |

| 📦 Lead Time | 20–25 days | 30–40 days |

| 📜 Compliance | FSC, CE, EUDR, BIS, CARB | FSC, CE, but limited EUDR readiness |

| 🔍 Transparency | High – clear sourcing & contracts | Mixed – risk of hidden specifications |

| 🔁 Reuse Cycles | 10–20 times in concrete projects | 8–12 times depending on supplier |

👉 Conclusion: In 2025, Vietnam is not just a cheaper alternative but the preferred source for film faced plywood.

📐 Technical Specifications & Grades

Thickness Options

One of the main reasons buyers search for the top 10 film faced plywood manufacturers in Vietnam 2025 is to secure consistent thickness across shipments. Vietnamese factories offer a full range of panels, including 9mm, 12mm, 15mm, 18mm, and 21mm boards.

Each thickness has its own use case. For example, 9mm is often used for lightweight scaffolding, while 18mm and 21mm are essential in heavy concrete formwork. Importers appreciate the flexibility to order mixed thicknesses in a single container, which simplifies inventory planning.

Core Types

Vietnamese manufacturers use several core structures:

- Poplar Core: Lightweight, affordable, suitable for short-term projects.

- Eucalyptus Core: Stronger, dense, preferred in India and the Middle East.

- Acacia Core: Excellent nail-holding capacity, ideal for premium projects.

- Combi Core: A mix of poplar and hardwood, balancing cost and strength.

This variety allows Vietnam film faced plywood suppliers to meet the exact technical demands of different markets.

Film GSM and Colors

The protective film layer is another critical factor. Factories offer film with GSM ratings of 120, 150, and 220. Higher GSM films provide longer durability and more reuse cycles in concrete applications.

Common film colors include brown, black, and red. Some importers prefer darker shades for premium branding, while others choose standard brown for cost efficiency.

By working with Vietnam film faced plywood exporters, buyers can request private labeling, customized film color, or branded stamping on the board surface.

Glue Types

Adhesive quality determines water resistance and durability. The main glue types available are:

- WBP Phenolic Glue: High resistance, withstands boiling water tests, ideal for humid climates.

- Melamine Glue: Cost-effective for medium-duty applications.

- MR (Moisture Resistant) Glue: Entry-level option for non-structural use.

The ability to choose glue type ensures buyers can balance cost and performance. This flexibility is one reason why the top 10 film faced plywood manufacturers in Vietnam 2025 remain competitive globally.

Why Specifications Matter

For international importers, clear specifications reduce disputes, improve project performance, and enhance trust in the supply chain. Vietnamese manufacturers provide detailed datasheets, thickness tolerance reports, and reuse cycle expectations.

👉 By aligning product specs with buyer requirements, the top plywood manufacturers in Vietnam prove that they are not only suppliers but also technical partners in construction success.

📜 Certifications & Compliance

Importance of Certification

For importers searching the top 10 film faced plywood manufacturers in Vietnam 2025, certificates are not optional—they are mandatory. Certifications prove that the plywood meets safety, environmental, and technical standards required in global markets. Without them, shipments risk being delayed, rejected, or fined at customs.

FSC Certification

The Forest Stewardship Council (FSC) certification ensures that the plywood originates from responsibly managed forests. Buyers in Europe, North America, and Australia increasingly demand FSC-certified products.

Most Vietnam film faced plywood suppliers offer FSC Mix or FSC 100% certification, making them attractive to importers with strict sustainability policies. This commitment to eco-friendly sourcing also helps build long-term trust with international buyers.

CE and EUDR Compliance for Europe

For the European Union, two major requirements dominate in 2025: CE certification and EUDR compliance.

- CE guarantees that plywood meets European safety and performance standards.

- EUDR (European Union Deforestation Regulation) ensures legal and sustainable sourcing.

Vietnamese factories have adapted quickly, providing the documents and traceability that European importers need. This makes Vietnam film faced plywood exporters a safe choice for EU buyers.

BIS Certification for India

India remains the single largest destination for Vietnamese film faced plywood. To access this market, manufacturers must secure BIS (Bureau of Indian Standards) certification.

Leading companies among the top plywood manufacturers in Vietnam 2025 already hold BIS approval, enabling smooth customs clearance and compliance with Indian government requirements. This gives Indian distributors confidence in both quality and legality.

CARB Certification for the USA

For buyers in the United States, the CARB (California Air Resources Board) certification is essential. It regulates formaldehyde emissions, protecting consumer safety and meeting environmental guidelines.

Several Vietnam film faced plywood suppliers have achieved CARB compliance, making them suitable partners for U.S. importers who cannot risk delays or penalties.

Why Compliance Gives Vietnam an Edge

The ability to supply multiple certificates across different markets is one of Vietnam’s greatest strengths. Buyers often need a single supplier capable of serving several destinations at once.

👉 By holding FSC, CE, EUDR, BIS, and CARB certifications, the top 10 film faced plywood manufacturers in Vietnam 2025 provide unmatched flexibility, ensuring smooth access to global markets without legal complications.

💵 Pricing & Market Trends 2025

Current Price Landscape

One of the main reasons buyers search for the top 10 film faced plywood manufacturers in Vietnam 2025 is to secure the most competitive pricing. In 2025, FOB prices from Vietnam remain 10–15% lower than Chinese suppliers, making the country a cost-effective choice for importers in India, the Middle East, and Africa.

Typical pricing ranges for 18mm film faced plywood (FOB Vietnam):

- Standard quality: $310–$330 per cubic meter

- Mid-grade phenolic: $340–$360 per cubic meter

- High-grade phenolic, FSC certified: $370–$400 per cubic meter

These figures vary by thickness, core material, and film GSM.

FOB vs CIF Considerations

Vietnamese manufacturers usually quote FOB Hai Phong or Ho Chi Minh. However, many Vietnam film faced plywood suppliers also offer CIF and CFR terms, shipping directly to ports in Mumbai, Dubai, or Istanbul.

Importers must weigh the benefits:

- FOB: Greater control over freight but requires strong logistics partners.

- CIF: Simplifies operations but can add hidden shipping costs.

The flexibility of Vietnamese exporters ensures buyers can negotiate terms that suit their specific trade preferences.

Market Trends in 2025

Global construction spending is rising, especially in Asia and Africa. This directly increases demand for film faced plywood. According to industry forecasts, Vietnam’s exports may grow by 12–15% in 2025, solidifying its role as a dominant player in the plywood market.

Key regions driving demand:

- India: Large infrastructure projects continue to absorb bulk volumes.

- Middle East (UAE, Saudi Arabia, Qatar): Mega-projects create ongoing demand for durable phenolic plywood.

- Europe: Increasing focus on FSC and EUDR compliance.

- South America: Brazil, Chile, and Peru emerging as new buyers.

Long-Term Cost Benefits

Buyers often evaluate not only initial pricing but also the reuse cycles of film faced plywood. Vietnamese products typically last 10–20 cycles, depending on core type and glue quality. This durability reduces the cost per use, making them more attractive compared to lower-quality alternatives.

👉 For importers looking at both price and performance, the top plywood manufacturers in Vietnam 2025 provide the best value: affordable upfront costs, reliable compliance, and long-term savings.

🚢 Importing Guide: HS Codes, Incoterms, and Logistics

HS Codes for Film Faced Plywood

For buyers dealing with customs clearance, knowing the correct HS code is essential. The most common HS code for film faced plywood is 4412.33 or 4412.39, depending on the core material and whether the board is surfaced with phenolic film.

- India: Importers typically declare under HS Code 4412.33.

- Middle East and Africa: Often classified as 4412.39.

- Europe and USA: Importers follow the harmonized system but must also ensure compliance with CE, EUDR, or CARB regulations.

By working with the top 10 film faced plywood manufacturers in Vietnam 2025, buyers can receive professional guidance on which HS code to use to avoid delays and extra duties.

Incoterms: FOB, CIF, and CNF

Incoterms define how costs and responsibilities are divided between the seller and the buyer.

- FOB (Free on Board): The exporter covers costs until the plywood is loaded on the vessel. The buyer arranges ocean freight and insurance.

- CIF (Cost, Insurance, and Freight): The exporter delivers the shipment all the way to the buyer’s port, including insurance.

- CNF (Cost and Freight): Similar to CIF, but insurance is arranged by the buyer.

Most Vietnam film faced plywood suppliers offer all three options. Importers should choose based on their own logistics experience. For new buyers, CIF may be simpler. For experienced traders with strong freight partners, FOB can reduce costs.

Container Loading

Efficient container loading saves money. A standard 40HC container can carry:

- 700–750 sheets of 18mm film faced plywood

- 850–900 sheets of 15mm

- 1,200+ sheets of 9mm

Leading Vietnam film faced plywood exporters such as HCPLY provide detailed loading plans, maximizing container space and reducing freight cost per cubic meter.

Practical Tips for Importers

- Confirm HS code with your local customs broker before shipping.

- Request both FOB and CIF quotes to compare total landed cost.

- Ask suppliers for photos and packing lists before shipment.

- Verify that the bill of lading, invoice, and packing list match customs requirements.

👉 By following these steps, importers working with the top plywood manufacturers in Vietnam 2025 can ensure smooth customs clearance, predictable costs, and timely delivery.

✅ Checklist for Buyers

Why a Checklist Matters

Importing plywood is not only about finding low prices. It requires due diligence to avoid delays, poor quality, or legal issues. That is why buyers searching for the top 10 film faced plywood manufacturers in Vietnam 2025 should follow a structured checklist. This ensures that every shipment is compliant, cost-effective, and delivered on time.

Step 1: Verify the Supplier

Always confirm that the factory is a genuine producer, not just a trading company.

- Request a copy of the business license.

- Ask for recent export documents (bill of lading, invoices).

- Check whether the supplier is listed among trusted Vietnam film faced plywood exporters.

A verified supplier reduces the risk of fraud and guarantees stable quality.

Step 2: Inspect Technical Specifications

Compare datasheets with actual requirements.

- Confirm thickness tolerance (±0.5mm).

- Ask about the number of reuses in concrete formwork.

- Review film GSM (120, 150, 220) and glue type (phenolic, melamine).

Reliable Vietnam film faced plywood suppliers will provide samples before bulk shipment.

Step 3: Check Certifications

Confirm which certificates are available for your market:

- FSC for sustainability

- CE and EUDR for Europe

- BIS for India

- CARB for the USA

Working with the top plywood manufacturers in Vietnam 2025 ensures that these certifications are already in place.

Step 4: Negotiate Payment and Incoterms

To minimize risk:

- For new suppliers, use L/C or a secure payment method.

- For established partners, T/T with deposits can reduce costs.

- Decide between FOB, CIF, or CNF based on your logistics capabilities.

The ability of Vietnamese exporters to offer flexible terms is a major advantage.

Step 5: Conduct Pre-Shipment Inspection

Before loading, arrange an inspection through a third party or request detailed packing photos and QC reports. This step helps avoid disputes once the goods reach your port.

Final Tip

Always build relationships, not just transactions. Importers who develop long-term partnerships with the top 10 film faced plywood manufacturers in Vietnam 2025 often receive better pricing, faster lead times, and priority during peak production seasons.

👉 Following this checklist gives buyers confidence that every order is secure, certified, and aligned with international trade practices.

📞 Conclusion & Call to Action

Why Vietnam is the Best Choice

After reviewing the top 10 film faced plywood manufacturers in Vietnam 2025, it is clear why global importers trust this country. Vietnam combines three key advantages: competitive prices, reliable export capacity, and compliance with international certifications.

Unlike other regions, Vietnamese suppliers deliver not just affordability but also long-term value. With reuse cycles of 10–20 times, proper film GSM, and phenolic glue options, their plywood performs strongly in both small and mega construction projects.

The Strategic Role of HCPLY

Among all suppliers, HCPLY – Vietnam Plywood HCPLY Co., Ltd is the standout. With over 5,000 containers shipped annually and certifications including FSC, CE, EUDR, and CARB, HCPLY provides unmatched reliability. Importers value its professional support team, fast lead times, and ability to optimize container loading for lower logistics costs.

This combination of scale and trust makes HCPLY the preferred partner for buyers seeking Vietnam film faced plywood suppliers with proven track records.

Building Long-Term Partnerships

Importing plywood is not a one-time purchase. Successful importers build strong relationships with manufacturers, ensuring priority access to production, flexible payment terms, and ongoing technical support.

By choosing one of the top plywood manufacturers in Vietnam 2025, especially HCPLY, buyers can create a stable and profitable supply chain for years to come.

📞 Conclusion & Call to Action

Why Vietnam is the Best Choice

After reviewing the top 10 film faced plywood manufacturers in Vietnam 2025, it is clear why global importers trust this country. Vietnam combines three key advantages: competitive prices, reliable export capacity, and compliance with international certifications.

Unlike other regions, Vietnamese suppliers deliver not just affordability but also long-term value. With reuse cycles of 10–20 times, proper film GSM, and phenolic glue options, their plywood performs strongly in both small and mega construction projects.

The Strategic Role of HCPLY

Among all suppliers, HCPLY – Vietnam Plywood HCPLY Co., Ltd is the standout. With over 5,000 containers shipped annually and certifications including FSC, CE, EUDR, and CARB, HCPLY provides unmatched reliability. Importers value its professional support team, fast lead times, and ability to optimize container loading for lower logistics costs.

This combination of scale and trust makes HCPLY the preferred partner for buyers seeking Vietnam film faced plywood suppliers with proven track records.

Building Long-Term Partnerships

Importing plywood is not a one-time purchase. Successful importers build strong relationships with manufacturers, ensuring priority access to production, flexible payment terms, and ongoing technical support.

By choosing one of the top plywood manufacturers in Vietnam 2025, especially HCPLY, buyers can create a stable and profitable supply chain for years to come.

Call to Action

👉 Ready to secure your supply of certified, cost-effective plywood?

- Visit HCPLY Official Website

- Contact David (Export Project Leader) at [email protected] | WhatsApp: +84-338616333

- Contact Lucy (Sales Manager) at [email protected] | WhatsApp: +84-975807426

- Request a free quotation and sample shipment today

✨ Final Thought

“Quality is remembered long after the price is forgotten.” – this timeless truth defines HCPLY’s philosophy.

Choosing HCPLY means more than buying plywood — it means partnering with a manufacturer that delivers trust, compliance, and global expertise. Importers worldwide already recognize HCPLY as Vietnam’s #1 film faced plywood exporter.

👉 Don’t just buy plywood. Build your future with HCPLY — where Vietnam’s strength meets the world’s demand.

Who is the leading manufacturer of plywood?

In 2025, HCPLY – Vietnam Plywood HCPLY Co., Ltd is widely recognized as the leading manufacturer of film faced plywood in Vietnam. With over 5,000 containers shipped annually, FSC/CE/EUDR/CARB certifications, and global clients across India, the Middle East, Africa, and Europe, HCPLY is the most trusted choice for importers.

Which is Asia’s largest plywood company?

While China has many large factories, Vietnam is now Asia’s most competitive hub for film faced plywood. HCPLY stands out among the top 10 film faced plywood manufacturers in Vietnam 2025, offering both scale and international compliance. Importers increasingly prefer Vietnam over China due to lower prices and stronger export reliability.

What is the future of the plywood industry?

The future of plywood is driven by sustainability, compliance, and cost efficiency. With FSC-certified forests, EUDR compliance, and eco-friendly production, Vietnam plywood exporters like HCPLY are shaping the industry’s future. Demand is forecasted to grow 12–15% annually as construction booms in Asia, Africa, and the Middle East.

Which country is famous for plywood?

Vietnam has become one of the most famous plywood-exporting countries. Known for competitive prices, strong certifications, and trusted exporters like HCPLY, Vietnam is now a preferred source for film faced plywood worldwide. Importers from India, UAE, Turkey, and Europe consistently rank Vietnam among the top plywood suppliers globally.