Table of contents

Top 10 Plywood Suppliers in Vietnam 2025-2026 — Full Market Comparison

The global demand for Vietnam plywood has surged across Europe, the Middle East, North America, and Latin America — pushing importers to search for truly reliable plywood suppliers in Vietnam. Buyers today no longer want a trading company; they want a factory partner with real production capacity, stable veneer quality, and export-level consistency.

This is why the “Top 10 Plywood Suppliers in Vietnam 2025-2026 — Full Market Comparison” was created. It provides a clear, updated, research-based overview of Vietnam’s plywood manufacturing landscape — helping buyers understand which factories lead in quality, scale, certifications, service, and reliability.

Throughout this guide, HCPLY is presented as one of Vietnam’s leading plywood manufacturers, suppliers, and exporters — with large-scale production, competitive pricing, and strict QC designed for European, Middle Eastern, and American markets.

1️⃣ Vietnam Plywood Market Overview 2025-2026 — Trends & Buyer Expectations

Vietnam’s plywood industry has entered a high-growth phase from 2025 to 2026, becoming one of the most competitive export hubs in Asia. Global importers searching for Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers are increasingly shifting orders from China, Malaysia, and Indonesia to Vietnam thanks to better pricing stability, improved veneer quality, and modernized production lines.

Across the EU (Italy, Poland, France, Belgium, Netherlands), North America (Canada, US), and Latin America (Honduras, Chile, Peru), buyers now expect Vietnam plywood to meet stricter standards: lower moisture, stronger bonding, zero-gap cores, and traceable materials. This demand evolution has pushed Vietnam to improve dramatically.

⭐ Market Growth & Export Expansion

Vietnam ships more than $1.6–2.0 billion of plywood annually, making it a top global exporter. Demand is strongest for:

- Film faced plywood for construction

- Commercial plywood for furniture, packaging, and general use

- High-grade calibrated plywood for EU factories

- Moisture-resistant MR/WBP plywood for North America

- FSC-certified plywood for Europe & Canada

Export volume is rising due to Vietnam’s ability to produce at competitive prices while still meeting EU + US compliance levels.

⭐ Buyer Expectations Are Now Much Higher

International importers are no longer accepting inconsistent quality from small factories. They now expect:

- Moisture 8–12%

- Thickness tolerance ±0.3–0.5mm

- Strong glue bonding (≥1.0 MPa)

- Clean face veneers

- Stable loading schedule

- Clear documentation (FSC, CARB, CE, EUDR)

- Full QC evidence before loading

Only suppliers with real, large-scale manufacturing can meet these expectations.

⭐ Shift From Traders to Real Manufacturers

Buyers searching for Plywood Suppliers in Vietnam are increasingly avoiding intermediaries. They want:

- Factory-direct pricing

- Factory transparency

- Real production photos & QC reports

- Clear responsibility for defects

- Long-term partnership capability

This eliminates low-quality, small workshops and elevates true manufacturers — especially HCPLY — which export consistently with strong QC and large capacity.

⭐ Why HCPLY Stands Out in This Market Landscape

As one of Vietnam’s leading plywood manufacturers and exporters, HCPLY has:

- Export-grade production lines

- High-volume monthly capacity

- Strict QC from veneer to loading

- Competitive, stable pricing

- Certifications for EU/US markets

- A proven track record serving Europe, Middle East, North America & Latin America

This makes HCPLY highly preferred among the Top 10 Plywood Suppliers in Vietnam for 2025–2026.

2️⃣ Key Quality Standards Required by Global Markets (EU, US, Middle East, LATAM)

For buyers searching for Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers, understanding the exact quality standards required by each export market is essential. Global importers no longer accept plywood that simply “looks good.” They now demand panels that meet strict technical benchmarks, traceability requirements, safety regulations, and long-term performance expectations.

⭐ EU Market Standards (Italy, Poland, France, Germany, Netherlands, Belgium)

The European Union has the most demanding requirements:

- E1/E0 formaldehyde emission

- EN 314-2 bonding strength

- EN 310 bending strength

- EN 315 tolerances

- FSC Mix / FSC 100%

- EUDR-compliant documentation & traceability

- Smooth, clean face veneer with minimal repairs

EU buyers reject panels with:

- Overfilled putty

- Unstable moisture

- Visible core lines

- Mixed waste wood layers

Only large-scale manufacturers with strict QC — such as HCPLY — consistently pass these requirements.

⭐ United States & Canada (CARB P2 / EPA TSCA Title VI)

North America requires strict compliance for formaldehyde and durability:

- CARB P2 / EPA TSCA Title VI certification

- Moisture control 8–12%

- Stable thickness tolerance

- High bonding strength for MR/WBP

- Strong core structure for furniture & cabinetry

Buyers in Canada and the U.S. expect long-term supply reliability and prefer Vietnam factories with:

- Automated veneer drying

- Calibrated cold-press/hot-press systems

- Full QC documentation

This is why HCPLY is a preferred partner for many North American distributors.

⭐ Middle East (UAE, Saudi Arabia, Qatar, Kuwait)

The Middle East accepts a wider range of grades but still requires:

- Durable glue systems (MR, WBP)

- Heat-resistant bonding (for high temperatures)

- Heavy-weight panels for construction

- Consistent film-faced plywood

Film faced plywood is the highest-demand product, and buyers favor factories with stable phenolic glue systems — a major strength of HCPLY.

⭐ Latin America (Honduras, Chile, Peru, Colombia)

Latin American buyers require:

- Strong core plywood for concrete formwork

- Durable film faced plywood

- Moisture control for tropical climates

- Stable weight and thickness per sheet

- High reusability (8–15 times)

These buyers often face challenges with Chinese-origin panels due to inconsistent bonding — pushing them toward Vietnam’s top manufacturers.

⭐ Why These Standards Matter for Buyers

Meeting these technical standards guarantees:

- Fewer claims and disputes

- Higher durability under real working conditions

- Better performance in construction or furniture manufacturing

- Long-term stability in supply and pricing

This is why global importers consistently choose the Top Plywood Suppliers in Vietnam, with HCPLY ranked as a leading manufacturer that meets or exceeds all export standards across EU, US, Middle East, and Latin American markets.

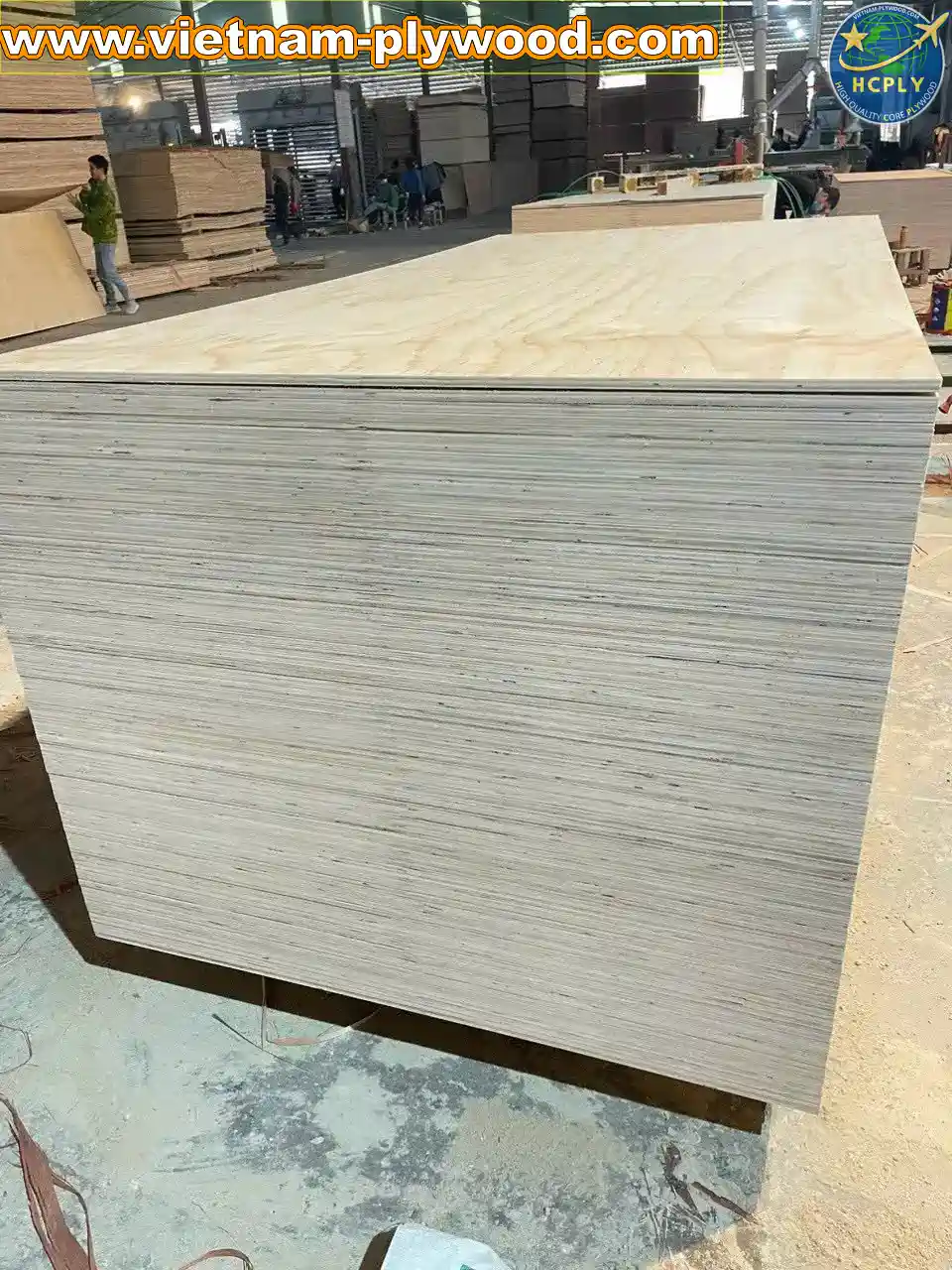

3️⃣ Production Capacity Comparison Among Top Plywood Suppliers in Vietnam

When international buyers search for Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers, one factor matters more than almost anything else: real, verifiable production capacity. Capacity determines stability, delivery speed, quality consistency, and long-term partnership potential — especially for buyers in Europe, the Middle East, North America, and Latin America.

⭐ Why Production Capacity Is the Key Indicator of a Reliable Supplier

High-capacity factories offer:

- Consistent veneer quality

- Stable monthly output

- Reliable lead times (even during peak season)

- Ability to handle mixed containers and diverse product lines

- Long-term price stability

- Stronger QC due to structured production flow

Low-capacity workshops often struggle with:

- Moisture instability

- Mixed or recycled core veneers

- Thin glue spread

- Late shipments

- Inconsistent quality from batch to batch

This is why experienced importers only work with the top-tier manufacturers.

⭐ Capacity Levels of Vietnam’s Plywood Industry (2025–2026)

Vietnam’s plywood factories fall into clear groups:

1. Large-Scale Export Manufacturers (20+ containers/month)

These are the true leaders — factories with:

- Automated peeling lines

- Modern hot-press systems

- Large drying capacity

- Skilled QC teams

- Full FSC/CARB/CE compliance

They produce:

- Film faced plywood

- Commercial plywood

- MR/WBP plywood

- FSC-certified plywood

- Calibration plywood for EU

HCPLY is firmly in this group, serving Italy, Poland, France, Belgium, Netherlands, Canada, US, UAE, Saudi Arabia, Honduras, Chile, and Peru.

2. Mid-Sized Factories (8–15 containers/month)

- Acceptable production quality

- Some inconsistencies in veneer supply

- Limited product customization

- Slower lead times

- Suitable mainly for regional or lower-grade markets

3. Small Workshops (1–5 containers/month)

- Not suitable for export-grade orders

- Often outsource veneer

- Poor moisture and bonding control

- Inconsistent performance

- Not compliant with EU/US certifications

Most buyer complaints in Vietnam originate from this category.

⭐ How HCPLY Compares to the Market

HCPLY stands out with:

- High production volume: capable of fulfilling large monthly orders

- Dedicated export lines: optimized for EU + US standards

- Factory-direct QC: every sheet inspected before loading

- Stable veneer sourcing: ensuring uniformity across all batches

- Automated hot-press and calibration: reducing tolerance errors

- Large workforce & skilled technicians: ensuring reliability year-round

This scale allows HCPLY to deliver:

- Consistent moisture (8–12%)

- Perfect core calibration

- Strong bonding values

- Smooth face veneer grading

- Quantity stability across long-term partnerships

⭐ Why Capacity Matters for Buyers in Europe, Middle East & LATAM

Large buyers require:

- 5–20 containers per month

- Repeatable weekly loading

- Fast documentation processing

- Ability to pass EU testing (EN standards)

- Film faced plywood with 8–15 reuses (LATAM)

- MR/WBP plywood for furniture, packaging, cabinetry

Only the top-tier Vietnamese suppliers—especially HCPLY—can meet these expectations continuously.

In the Vietnam plywood market, capacity = reliability — and HCPLY remains one of the strongest, most scalable plywood manufacturers and exporters in the country for 2025–2026.

4️⃣ Certifications, Compliance & Export Legitimacy (FSC, CE, CARB, EUDR, etc.)

For global buyers searching Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers, certifications are no longer optional — they are mandatory proof of legitimacy, safety, and long-term reliability. The international market (EU, US, Middle East, LATAM) is tightening regulations, creating a clear divide between true manufacturers and small workshops that cannot meet compliance requirements.

Top suppliers — especially HCPLY — invest heavily in certification systems, documentation control, and traceability to ensure their plywood products pass every market barrier.

⭐ FSC Certification (FSC Mix / FSC 100%)

The EU, Canada, and many global brands now require:

- FSC Chain of Custody (CoC)

- FSC Mix Credit or FSC 100% products

- Full traceability from forest to factory

Benefits for buyers:

- No risk of illegal timber

- Smooth customs clearance

- Meets government and NGO sustainability requirements

HCPLY provides FSC-certified plywood to Italy, Poland, France, Netherlands, Belgium, and Canada.

⭐ CE Marking (EN Standards Compliance)

Essential for plywood entering Europe (Italy, France, Germany, Spain, Netherlands, Belgium).

Key EN standards for plywood:

- EN 13986 — CE marking regulation

- EN 314-2 — bonding strength

- EN 310 — bending strength

- EN 315 — tolerance requirements

- EN 717-1 — formaldehyde emission

EU importers heavily penalize non-compliance — making CE-compliant factories the top choice.

HCPLY manufactures EN-compliant plywood designed for EU testing labs.

⭐ CARB P2 & EPA TSCA Title VI (USA & Canada)

North American buyers require:

- CARB Phase 2 certification

- EPA TSCA Title VI compliance

- Emission levels ≤ 0.05 ppm

Non-compliant shipments risk rejection, destruction, or heavy penalties.

HCPLY consistently meets CARB/EPA standards for furniture-grade plywood and commercial plywood.

⭐ EUDR Compliance (EU Deforestation Regulation – 2025 Enforcement)

This is the newest and strictest requirement for entry into the EU market.

Suppliers must provide:

- Verified supply chain documentation

- Legal sourcing evidence

- Timber origin traceability

- Geolocation data in some cases

Most small workshops cannot comply.

Large, organized manufacturers — such as HCPLY — already maintain documentation systems aligned with EUDR standards.

⭐ Middle East Certifications

While less strict than EU/US, major markets such as UAE, Saudi Arabia, and Qatar demand:

- High bonding strength (MR/WBP)

- Heat-resistant adhesives

- Consistent weight and thickness

- Clear origin declaration

Film faced plywood is the top demand category, and HCPLY’s phenolic bonding strength meets heavy construction requirements.

⭐ Latin America Compliance Standards (Honduras, Chile, Peru, Colombia)

LATAM buyers require:

- Strong plywood for concrete formwork

- High reuse cycles (8–15 times)

- Moisture-resistant cores

- Stable density levels

- Reliable export paperwork

Many LATAM projects follow European engineering standards, making compliance even more critical.

HCPLY exports construction-grade plywood widely across Central and South America.

⭐ Why Certifications Define the Real “Top Suppliers”

Only true manufacturers — not trading companies or small workshops — can maintain:

- Strict documentation

- Emission compliance

- Glue testing reports

- Regular third-party audits

- Traceable raw material sources

- Export legitimacy

HCPLY stands out because:

- It is a real factory, not a middleman

- It maintains global certification systems

- It exports directly to EU, US, Middle East, and Latin America

- It consistently passes international testing standards

Certifications are the backbone of global plywood trade — and HCPLY is recognized as one of Vietnam’s most compliant, fully certified plywood manufacturers and exporters for 2025–2026.

5️⃣ Raw Materials & Core Veneer Quality — Hardwood, Acacia, Eucalyptus, Mixed Core

The foundation of every high-quality plywood sheet is the core veneer — and global buyers searching for Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers are becoming far more demanding about raw material selection, traceability, and consistency. This shift is especially strong in Europe (Italy, Poland, France, Germany), Canada, the U.S., and high-humidity regions such as the Middle East and Latin America.

As one of Vietnam’s leading plywood manufacturers and exporters, HCPLY has long recognized that stable veneer input = stable plywood performance. This is why our factory invests heavily in controlled sourcing, strict grading, moisture stabilization, and deep QC throughout the veneer supply chain.

🌳 The 4 Main Veneer Types Used in Vietnam’s Plywood Industry

Below is an accurate, market-aligned comparison that importers rely on when evaluating suppliers:

1. Hardwood Core (Acacia/Hardwood Mix)

- Strong mechanical properties

- High density suitable for furniture & construction

- Better screw-holding ability

- Ideal for EU calibrated plywood and NA cabinets

- Most stable option for long-term export projects

2. Acacia Core

- Vietnam’s most reliable plantation wood

- Good bonding absorption

- Excellent for MR/WBP furniture plywood

- Suitable for EU, US, and Middle East markets

- Mid-weight but strong structural integrity

3. Eucalyptus Core

- Higher density than acacia

- Strong bending strength

- Preferred in Middle East and LATAM for formwork

- Performs well in harsh temperature conditions

4. Mixed Core (Acacia + Eucalyptus)

- Cost-effective solution

- Balanced strength/weight ratio

- Suitable for packaging, general commercial plywood

- Must be sourced carefully — poor suppliers mix recycled layers

HCPLY ensures zero recycled veneer, no hollow gaps, no dead knots, and fully calibrated layers, delivering a consistently strong product trusted by top importers worldwide.

💧 Moisture Content: The Make-or-Break Factor

Global buyers demand:

- 8–12% moisture, stable at every layer

- Controlled drying using monitored kilns

- Bonding strength ≥ 1.0 MPa

Factories with inadequate drying create:

- Weak bonding

- Warping

- Delamination during shipping

- Surface bubbles during pressing

HCPLY’s veneer drying lines operate with digital moisture calibration, ensuring every sheet meets export-grade levels.

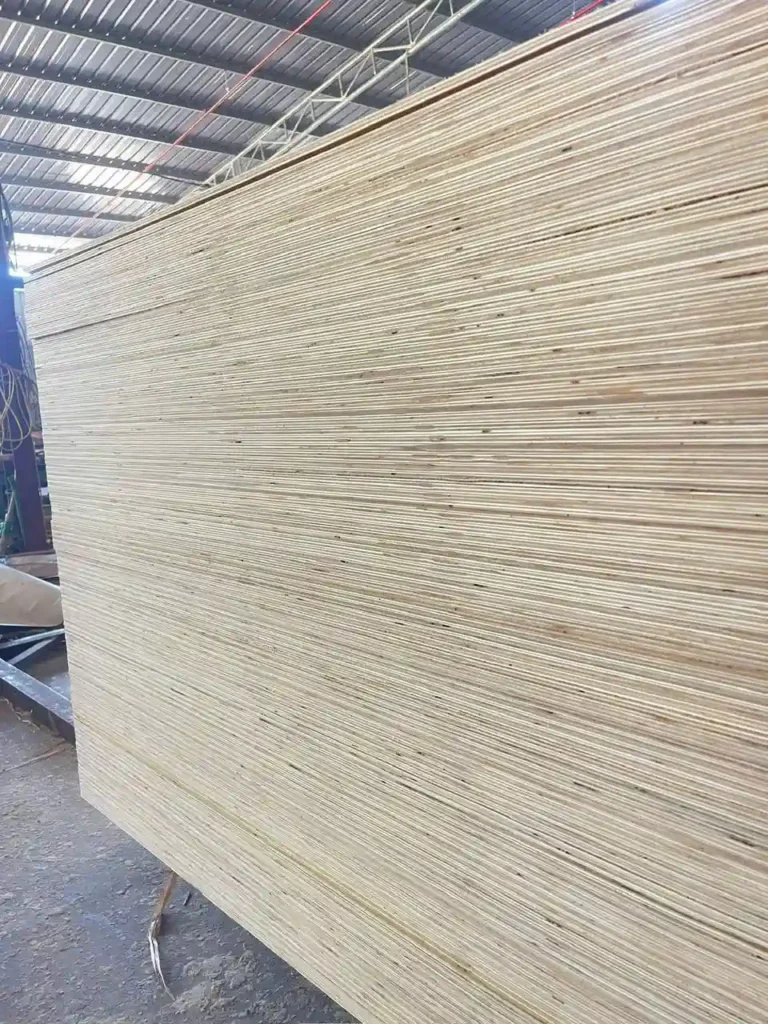

🧩 Core Structure & Internal Stability

HCPLY follows strict specifications required by EU & NA markets:

- Evenly distributed core layers

- Symmetrical construction

- No overlap, no gaps

- Tight jointing

- Clean cross-grain bonding

This gives HCPLY plywood:

- Better flatness

- Reduced deformation

- Stronger screw retention

- Longer life in both furniture and construction use

🚫 Common Problems Found in Lower-Tier Suppliers

Many complaints about Vietnam plywood come from small workshops producing:

- Recycled or mixed-waste core veneers

- Over-dried veneer (brittle)

- Wet veneer (weak bonding)

- Hollow gaps & overlaps

- Excessive putty fill

- Unstable thickness

These issues cause container claims and heavy losses for importers — which is why experienced buyers avoid low-tier producers.

⭐ Why HCPLY Leads the Market in Raw Material Quality

HCPLY stands out among the Top 10 Plywood Suppliers in Vietnam thanks to:

- Direct partnerships with certified veneer plantations

- FSC-compliant sourcing for EU & Canada

- Moisture-controlled veneer preparation

- Full transparency: real factory videos, QC reports, and batch documentation

- Calibrated cores for furniture & construction

- Stability and consistency across 12 months of production

With large-scale capacity, modern machinery, and strict QC, HCPLY delivers plywood that meets or exceeds the expectations of demanding markets across the EU, U.S., Middle East, and Latin America — reinforcing our position as one of Vietnam’s leading plywood manufacturers, suppliers, and exporters.

6️⃣ Glue Systems & Bonding Strength — MR, WBP, Phenol, Melamine

Choosing the right glue system is one of the most critical factors when evaluating Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers.

Glue quality determines bonding strength, durability, moisture resistance, reusability, and suitability for specific global markets (EU, US, Middle East, LATAM).

Vietnam’s top manufacturers — including HCPLY — use different adhesive systems depending on export requirements, plywood type, and performance expectations.

⭐ MR (Moisture Resistant) Glue

Recommended for: furniture, packaging, cabinetry, indoor applications

Common Markets: EU, US, Canada, Middle East, India

Key characteristics:

- Resistant to humidity but not waterproof

- Suitable for interior use

- Low formaldehyde emission available (E1/E0/CARB)

Typical bonding strength:0.6 – 0.9 MPa

What top buyers check:

- Glue spread rate consistency

- No delamination during manual break tests

- Moisture 8–12% for stable bonding

HCPLY Advantage: MR boards with calibrated cores and uniform bonding ensure fewer claims.

⭐ WBP (Water Boil Proof) Glue

Recommended for: higher-end furniture, packaging, marine use, general outdoor applications

Common Markets: EU, Middle East, LATAM

Key characteristics:

- Survives boiling water 4–72 hours depending on grade

- Higher bonding durability under moisture

- Used in commercial plywood & some film faced plywood

Typical bonding strength:0.9 – 1.2 MPa

Buyer expectations:

- Stable hot-press temperature (≥125–135°C)

- Accurate glue mix ratio (phenol or melamine based)

- Even glue penetration

HCPLY Advantage: Automated glue mixing systems produce consistent WBP-quality panels.

⭐ Phenolic Glue (PF) — Highest Strength

Recommended for:

- Film faced plywood

- Concrete formwork

- Heavy construction

- LATAM + Middle East + EU projects

Key characteristics:

- Ultimate waterproof performance

- Best durability & heat resistance

- Longest reusability cycles (8–15+ times for F17-grade film faced plywood)

Typical bonding strength:1.0 – 1.5+ MPa

Buyer checks:

- Reuse cycles in concrete (LATAM requires 8–15)

- Glue penetration and drum test results

- Weight consistency per sheet

HCPLY Advantage: Phenolic bonding is one of HCPLY’s strongest export capabilities, especially for construction buyers.

⭐ Melamine (MF) Glue

Recommended for:

- Commercial plywood

- Mixed-core plywood

- Furniture-grade applications

Key characteristics:

- Mid-range waterproofing (stronger than MR, weaker than PF)

- Good surface bonding

- Suitable for markets requiring controlled moisture but not full waterproofing

Typical bonding strength:0.8 – 1.1 MPa

Why importers choose MF:

- Balance of cost + performance

- Allows competitive pricing while meeting export-grade requirements

HCPLY Advantage: Melamine-improved WBP products designed for EU & Middle East mid-tier demand.

🔍 Comparison Table — Glue Systems Used by Vietnam’s Top Suppliers

| Glue Type | Waterproof Level | Bonding Strength | Common Use | Export Markets | Cost Level |

|---|---|---|---|---|---|

| MR | ⭐ | 0.6–0.9 MPa | Furniture, packaging | EU/US/ME | Low |

| Melamine (MF) | ⭐⭐ | 0.8–1.1 MPa | Commercial plywood | EU/ME/LATAM | Medium |

| WBP | ⭐⭐⭐ | 0.9–1.2 MPa | Outdoor-use plywood | EU/ME/LATAM | Medium–High |

| Phenolic (PF) | ⭐⭐⭐⭐ | 1.0–1.5+ MPa | Film faced plywood, construction | ME/LATAM/EU | High |

🔍 What Global Buyers Check Before Approving a Glue System

EU Buyers (Italy, Poland, France, Netherlands)

- EN 314-2 bonding

- E1/E0 emission

- Long-term bonding stability

US & Canada

- CARB P2 / EPA TSCA Title VI

- Moisture 8–12%

- Strong core bonding for cabinetry

Middle East

- Heat resistance

- Strong PF bonding for high-temp environments

Latin America (Honduras, Chile, Peru)

- Film faced plywood with 8–15 reuses

- Strong phenolic glue penetration

- No delamination in tropical humidity

🔥 Why HCPLY’s Glue Systems Stand Out

HCPLY maintains automated glue mixing systems + calibrated hot-press lines to ensure:

- Accurate glue ratio

- Deep glue penetration

- Strong bonding values

- Compliance with EU/US testing standards

- Zero-delamination performance in extreme climates

This makes HCPLY one of Vietnam’s most competitive and trustworthy plywood manufacturers for 2025–2026.

7️⃣ Film Faced & Commercial Plywood Specialization Among Vietnam Suppliers

Global buyers searching for Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers increasingly evaluate factories based on product specialization. Not every manufacturer in Vietnam can produce both Film Faced Plywood (FFP) and Commercial Plywood at export-grade consistency — and this specialization often determines real market reliability, especially for Europe, the Middle East, North America, and Latin America.

Below is the most accurate, expert-level breakdown of how Vietnam’s leading plywood suppliers position themselves in the global market.

⭐ 1. Film Faced Plywood (FFP) — Vietnam’s Most Competitive Export Category

Film Faced Plywood is the #1 demand driver for Honduras, Chile, Peru, Colombia, the UAE, Saudi Arabia, and high-volume construction markets worldwide.

Top-grade FFP requires strict control of:

- 100–220 gsm film (Dynea, AICA, local phenolic film)

- Phenolic WBP glue (true WBP ≥ 1.0–1.2 MPa)

- Eucalyptus / hardwood / acacia cores

- Hot-press cycles above 125–135°C

- Calibration before film lamination

- Waterproof edge sealing

What buyers expect from leading suppliers:

- 8–15 reuses depending on grade

- Consistent 18mm thickness

- Uniform density (≥ 620–640 kg/m³)

- No bubble marks or delamination

- Stable weight per sheet

This category sharply differentiates strong factories from low-tier workshops.

HCPLY is recognized as a top producer of film faced plywood for LATAM and Middle East due to stable bonding, smooth film finish, and strong core structure.

⭐ 2. Commercial Plywood — The Backbone of Vietnam’s Furniture & Packaging Exports

Commercial plywood dominates exports to Italy, Poland, France, Canada, and the U.S.

Common constructions include:

- MR glue

- E0/E1 low-formaldehyde plywood

- Hardwood, acacia, or mixed cores

- Calibrated plywood for furniture factories

- Packaging-grade plywood for industrial use

High expectations from EU/US buyers:

- Fully calibrated surface

- Clean face veneer (A/B grade options)

- Thickness tolerance ±0.3–0.5mm

- 8–12% moisture

- No core overlaps or gaps

Many factories can produce commercial plywood, but only a small number can achieve export-level consistency — making this a key benchmark when comparing suppliers.

⭐ 3. Which Factories Specialize in FFP vs. Commercial Plywood?

Vietnamese factories naturally fall into three groups:

Group A — Large-Scale Export Specialists

(FFP + Commercial + FSC + CARB)

- High-capacity factories (20+ containers/month)

- Advanced calibration + hot-press systems

- Verified QC teams

- Suitable for EU, US, Middle East, LATAM

HCPLY belongs to this category.

Group B — Mid-Level Manufacturers

(Commercial plywood focus)

- Limited FFP performance

- Useful for regional markets

- Not ideal for EU/LATAM formwork buyers

Group C — Small Workshops

- Not suitable for export

- High defect rates

- Inconsistent glue spread & moisture

- No certification capability

Most serious importers avoid Group C entirely.

⭐ 4. Why Specialization Matters for International Buyers

Each global market prioritizes different plywood types:

Europe & Canada:

- FSC plywood

- E0/E1 emission

- Calibrated furniture plywood

Middle East:

- Heavy-duty film faced plywood

- WBP/MR plywood

- Heat-resistant bonding

Latin America:

- High-reuse film faced plywood (8–15 times)

- Strong eucalyptus cores

- 100–120 gsm brown or black film

North America:

- CARB/EPA-compliant commercial plywood

- Stable MR/WBP bonding

- Smooth face veneers

Only factories with true specialization can meet these varied demands consistently.

⭐ 5. Why HCPLY Excels in Both Categories

HCPLY is one of the few Vietnam suppliers that can simultaneously deliver:

- Export-grade Film Faced Plywood (LATAM + Middle East)

- High-quality Commercial Plywood (EU + US + Canada)

- FSC materials for Europe & Canada

- CARB/EPA-compliant plywood for North America

- Custom specifications and mixed containers

This dual specialization is why HCPLY consistently ranks among the Top 10 Plywood Suppliers in Vietnam for 2025–2026.

8️⃣ Price Comparison & Cost Structure: What Affects FOB/CIF Pricing?

Global buyers searching for Plywood Suppliers in Vietnam understand that pricing is never random — it is the result of structured production costs, raw material quality, glue systems, labor, compliance requirements, and factory-scale efficiency. The Top 10 Plywood Suppliers in Vietnam consistently follow transparent, stable costing methods, while smaller workshops often fluctuate wildly. As one of Vietnam’s leading plywood manufacturers, suppliers, and exporters, HCPLY provides buyers with predictable, competitive, factory-direct pricing optimized for long-term partnerships.

⭐ 8.1 Raw Material Costs — Core Veneer & Face Veneer

Raw materials account for 50–65% of total plywood cost. Key factors:

- Hardwood / Acacia / Eucalyptus veneer price changes weekly.

- Thick calibrated cores cost more than mixed-light cores.

- Premium face veneers (Bintangor, Okoume, Pine, Birch) increase cost.

- FSC-certified veneer carries a higher compliance cost.

Top-tier Plywood Suppliers in Vietnam maintain large veneer reserves to keep prices stable — HCPLY is among the few factories with long-term veneer contracts to avoid sudden price spikes.

⭐ 8.2 Glue System Cost — MR, MF, WBP, Phenolic

Glue represents 12–18% of sheet cost. Export markets force factories to use stronger, more expensive glue:

- MR → lowest cost, indoor use.

- Melamine → mid-cost, stronger bonding.

- WBP → higher cost, used for outdoor and commercial plywood.

- Phenolic PF → highest cost, required for film faced plywood with 8–15 reuses.

HCPLY uses automated glue-mixing systems to optimize glue penetration and reduce waste — creating a more competitive price for buyers while meeting global bonding requirements.

⭐ 8.3 Film Type & GSM (for Film Faced Plywood)

Film cost affects final price significantly:

- 120gsm brown film → affordable

- 150gsm → higher durability, higher cost

- 180gsm → premium

- Dynea / AICA film → top-tier international brands, highest cost

Leading Plywood Suppliers in Vietnam export all grades, but HCPLY specializes in phenolic-film products for demanding EU, Middle East & LATAM buyers.

⭐ 8.4 Pressing Technology & Calibration

Factories with outdated machinery have:

- Poor thickness accuracy

- Weak bonding

- Higher defect rate

Modern manufacturers like HCPLY use:

- Digital hot-press systems

- Automated cold-press lines

- Calibration machinery

These reduce production loss and keep FOB prices more stable — a major advantage for global buyers.

⭐ 8.5 Labor, Packing & Handling

Labor cost affects:

- Core jointing quality

- Face repair quality

- Edge trimming

- Packing strength

Export-grade packaging (waterproof wrap, corner protection) adds cost but reduces claim risk — a standard among the best Plywood Suppliers in Vietnam, including HCPLY.

⭐ 8.6 Compliance Cost — FSC, CE, CARB, EUDR

Certifications add 2–8% to production cost due to:

- Laboratory testing

- Documentation systems

- Traceability audits

- Formaldehyde compliance

Small workshops cannot meet these standards — which is why professional importers always choose certified factories like HCPLY.

⭐ 8.7 Logistics & Seasonality

Pricing also fluctuates due to:

- Exchange rate USD/VND

- Ocean freight to EU/USA/LATAM

- Peak-season demand (July–Dec)

- Local supply chain congestion

HCPLY negotiates long-term shipping contracts to help buyers achieve stable CIF pricing.

⭐ Why HCPLY Offers Some of the Most Competitive Prices in Vietnam

As a leading plywood manufacturer, supplier, and exporter in Vietnam, HCPLY achieves stable and competitive pricing due to:

- Large-scale production capacity

- Direct veneer sourcing

- Automated glue & pressing systems

- Strict QC minimizing defect-related loss

- Export-optimized packing

- Compliance with EU/US/Middle East/LATAM standards

HCPLY’s cost structure is optimized for long-term partnerships, making us one of the most trusted choices among the Top 10 Plywood Suppliers in Vietnam for 2025–2026.

9️⃣ Common Buyer Problems When Importing From Vietnam & How Top Suppliers Solve Them

Global importers searching for Top 10 Plywood Suppliers in Vietnam, Plywood Suppliers in Vietnam, or Vietnam Plywood Suppliers often report recurring issues when buying from small workshops or trading companies. These problems create delays, financial losses, and customer dissatisfaction — especially for buyers in Europe, the Middle East, Canada, the U.S., and Latin America.

Understanding these challenges is essential, and choosing the right supplier determines whether an importer faces costly claims or receives stable container-after-container quality. Below is the most accurate and experience-based analysis of common issues — and how leading Vietnamese plywood manufacturers like HCPLY fully eliminate them.

⭐ 9.1 Inconsistent Quality Between Shipments

One of the biggest complaints among international buyers is variation between samples, trial orders, and real production.

Common problems with lower-tier suppliers:

- Core veneer changes each shipment

- Random density fluctuations

- Glue quality substituted

- Face veneer downgraded

- Delamination during shipping

- Sheets warped due to moisture instability

How leading suppliers fix this:

- Fixed veneer source contracts

- Standardized QC procedures

- Moisture-controlled production

- Real-time production videos & batch reports

- Pre-loading inspection + vessel-day monitoring

HCPLY’s export consistency is one of the strongest in Vietnam, with controlled raw materials and strict calibration for every batch.

⭐ 9.2 Hidden Core Gaps & Overlaps (Major Cause of Claims)

Lower-tier suppliers frequently use:

- Recycled veneers

- Broken inner plywood pieces

- Overlaps to hide structural defects

- Hollow gaps that reduce strength

These defects cause failures especially in:

- EU furniture factories

- LATAM concrete formwork

- Middle East construction sites

HCPLY ensures:

- No recycled core

- Symmetrical internal structure

- Tight core jointing

- Laser-checked calibration

- Guaranteed strength & stability

⭐ 9.3 Wrong Moisture Content (Too Wet / Too Dry)

Moisture is the silent killer of plywood import quality.

Too wet → swelling, bending, mold

Too dry → brittle core, surface cracking

Common among small factories with manual drying.

HCPLY uses:

- Digital kiln-drying

- Layer-by-layer moisture calibration

- Final QC to ensure 8–12% export-grade moisture

This prevents container claims and ensures smooth processing in furniture factories and on construction sites.

⭐ 9.4 Incorrect Glue Ratio → Weak Bonding

Glue cost is one of the biggest temptations for small producers to downgrade.

Risks for buyers:

- Quick delamination

- Failed boil tests

- Poor reusability for film faced plywood

- Rejects at EU/US customs for low bonding strength

Leading Plywood Suppliers in Vietnam like HCPLY avoid this by:

- Automated glue-mixing systems

- Strict ratio control

- Binding testing for each batch (lab + drum tests)

- Export-specific glue type (MR / WBP / PF / MF)

⭐ 9.5 Wrong Thickness & Poor Calibration

Many complaints from importers:

- 18mm delivered as 17.2–17.5mm

- Uneven surfaces damaging CNC bits

- Core wave patterns visible under veneer

Leading suppliers fix this through:

- German/Italian calibration machines

- Dual-side sanding

- Pre-press alignment

- Digital veneer layering

HCPLY guarantees thickness tolerance within ±0.3–0.5mm, matching EU, US & Canadian requirements.

⭐ 9.6 Packaging Damage During Shipping

Common issues:

- Weak pallets collapse during unloading

- Film faced plywood edges become exposed

- Water enters during transit

- Poor strapping leads to movement inside container

Top suppliers solve this using:

- Heavy-duty pallets

- Waterproof wrapping

- Corner protectors

- Internal strapping

- Container floor moisture barriers

HCPLY uses reinforced export packaging for all shipments.

⭐ 9.7 Lack of Certification (EU/US Buyers Especially Affected)

Low-tier suppliers often fail to provide:

- FSC

- CE

- CARB/EPA

- EUDR compliance

- Phytosanitary documents

- Legally verified origin

This leads to customs rejection or expensive delays.

HCPLY provides full certification, including FSC, CARB, and EUDR-aligned sourcing.

⭐ 9.8 Late Delivery & Production Delays

Common causes:

- Limited capacity

- Manual production lines

- Seasonal labor shortages

- Unpredictable veneer supply

Top-tier suppliers like HCPLY minimize delays with:

- Large monthly capacity (20–40 containers/month)

- Automated machinery

- Strong supply-chain partnerships

- Production planning and buyer forecasting

⭐ 9.9 Miscommunication & No Real Factory Support

Trading companies often:

- Don’t control production

- Don’t provide real QC updates

- Cannot handle urgent orders

- Push responsibility back to the mill

Real manufacturers like HCPLY offer:

- Direct factory communication

- Daily production photos

- Video inspections

- Real-time QC reports

- Faster decision-making

- Clear loading supervision

⭐ 9.10 Why HCPLY Solves All These Problems for Global Buyers

HCPLY is recognized among the Top 10 Plywood Suppliers in Vietnam because it eliminates the major risks of importing from Vietnam through:

- Real in-house production (not trading)

- Automated glue systems

- Digital moisture control

- Large-scale veneer sourcing

- Strong FSC/CARB/EUDR alignment

- Strict internal QC at every stage

- Transparent communication

- Mixed container capability

- Export packaging designed for long-distance transit

HCPLY consistently delivers stable, high-quality plywood to demanding markets across Italy, Poland, France, Germany, the Netherlands, Canada, the U.S., the UAE, Saudi Arabia, Qatar, Honduras, Chile, Peru, Colombia, and more — reinforcing our position as a leading plywood manufacturer, supplier, and exporter in Vietnam.

🔟 Why HCPLY Is a Leading Plywood Manufacturer & Exporter in Vietnam (2025–2026)

Among all Top 10 Plywood Suppliers in Vietnam, HCPLY stands out as a factory that consistently delivers high-performance plywood to Europe, Canada, the U.S., the Middle East, and Latin America. Buyers searching for Plywood Suppliers in Vietnam or Vietnam Plywood Suppliers repeatedly choose HCPLY because of our unmatched stability, large-scale capacity, and proven export performance. Below is the clearest explanation of why HCPLY is recognized as one of Vietnam’s strongest plywood manufacturers, suppliers, and exporters.

⭐ 10.1 True Factory — Not a Trading Company

HCPLY controls the entire production chain:

- Veneer peeling, grading, and jointing

- Hot-pressing & cold-pressing

- Glue mixing (automated systems)

- Calibration & sanding

- Film lamination for FFP

- Final QC & loading supervision

This ensures batch-to-batch consistency unmatched by trading companies.

⭐ 10.2 Large Monthly Production Capacity

HCPLY operates with stable, high-volume output:

- 20–40 containers/month depending on season

- Multiple production lines to avoid delays

- Priority allocation for long-term buyers

- Ability to handle urgent or mixed orders

This makes HCPLY one of the few suppliers in Vietnam capable of serving large-scale distributors and construction groups.

⭐ 10.3 Specialized in Both Commercial & Film Faced Plywood

Many factories can only specialize in one category.

HCPLY is fully capable of both:

Commercial Plywood (EU/US/Canada markets)

- E0/E1/CARB compliance

- Fully calibrated

- Clean face veneers

- Tight thickness tolerance

Film Faced Plywood (LATAM/Middle East markets)

- Phenolic glue ≥ 1.0–1.2 MPa

- 100–220 gsm film

- 8–15 reuse cycles

- Eucalyptus / hardwood cores

This dual strength is a major reason HCPLY ranks among top Vietnamese suppliers.

⭐ 10.4 Certified for Global Compliance (EU, US, Middle East, LATAM)

HCPLY maintains full export legitimacy:

- FSC® Certified materials

- CARB/EPA compliant commercial plywood

- EN 314-2 bonding for EU

- EUDR-ready traceability

- Phytosanitary & fumigation certificates

- CO / Invoice / Packing List / B/L accuracy

This ensures smooth customs clearance worldwide.

⭐ 10.5 Strong QC System Trusted by International Buyers

HCPLY uses a 5-stage inspection system:

- Veneer grading

- Moisture control

- Glue penetration testing

- Calibration check

- Final inspection before loading

Every export order includes photos, videos, and QC reports.

⭐ 10.6 Competitive & Stable Pricing

Factory-direct pricing is optimized through:

- Long-term veneer sourcing

- Automated systems reducing waste

- Efficient labor allocation

- Export-optimized packaging

- Shipping contracts for stable CIF rates

This allows HCPLY to offer some of Vietnam’s most stable and competitive prices.

⭐ 10.7 Strong Experience With Europe, Canada, U.S., Middle East & LATAM

HCPLY supplies to:

- Italy, Poland, France, Germany, Netherlands

- Canada, USA

- UAE, Saudi Arabia, Qatar

- Honduras, Chile, Peru, Colombia

Each market has unique requirements — HCPLY meets them all.

⭐ 10.8 Mixed Container Expertise

HCPLY can load:

- Mixed plywood types

- Different sizes (1220×2440 / 1250×2500)

- Different thicknesses

- Multiple product lines (FFP + commercial + packing plywood)

Ideal for importers optimizing inventory & cash flow.

⭐ 10.9 Full After-Sales & Claim Prevention

HCPLY prevents claims through:

- Strict calibration

- Correct moisture 8–12%

- Verified glue ratio

- Reinforced export packaging

In rare cases of issues, HCPLY resolves quickly and transparently as a real manufacturer.

⭐ 10.10 Why Global Buyers Rank HCPLY Among the Top 10 Plywood Suppliers in Vietnam

Because HCPLY consistently delivers:

- Real factory production

- Certified materials

- Strong QC

- Stable quality

- Competitive pricing

- Large-capacity supply

- Market-specific understanding

- Professional communication

- Long-term reliability

This is why HCPLY is widely recognized as one of the leading Plywood Suppliers in Vietnam and a trusted partner for international importers in 2025–2026.

As we close this in-depth guide, what truly matters is not just the information you’ve gained — but the confidence and peace of mind you feel when choosing the right partner in Vietnam. In a global plywood market filled with risks, shifting prices, inconsistent quality, and complex compliance requirements, you deserve a manufacturer who delivers stability, integrity, and long-term value.

HCPLY is not only ranked among the Top 10 Plywood Suppliers in Vietnam — we are one of the country’s leading manufacturers, suppliers, and exporters, trusted by demanding buyers across Italy, Poland, France, Germany, Canada, the U.S., Honduras, Chile, Peru, the UAE, Saudi Arabia, and many more.

Every container we ship carries more than plywood — it carries our commitment to strength, precision, consistency, and trust.

Every sheet reflects the pride of Vietnamese craftsmanship and the reliability of a factory built for global standards.

If you are searching for a long-term partner who offers competitive pricing, export-grade quality, fast communication, strong QC, and the stability needed to scale your business — HCPLY is ready to support you today and for many years ahead.

HCPLY — Real Capacity. Real Quality. Real Value. Vietnam’s Leading Plywood Manufacturer, Supplier & Exporter for Global Markets.