Table of contents

Top 10 Plywood Exporters in Vietnam 2025 — Global Market Analysis & Export Strength

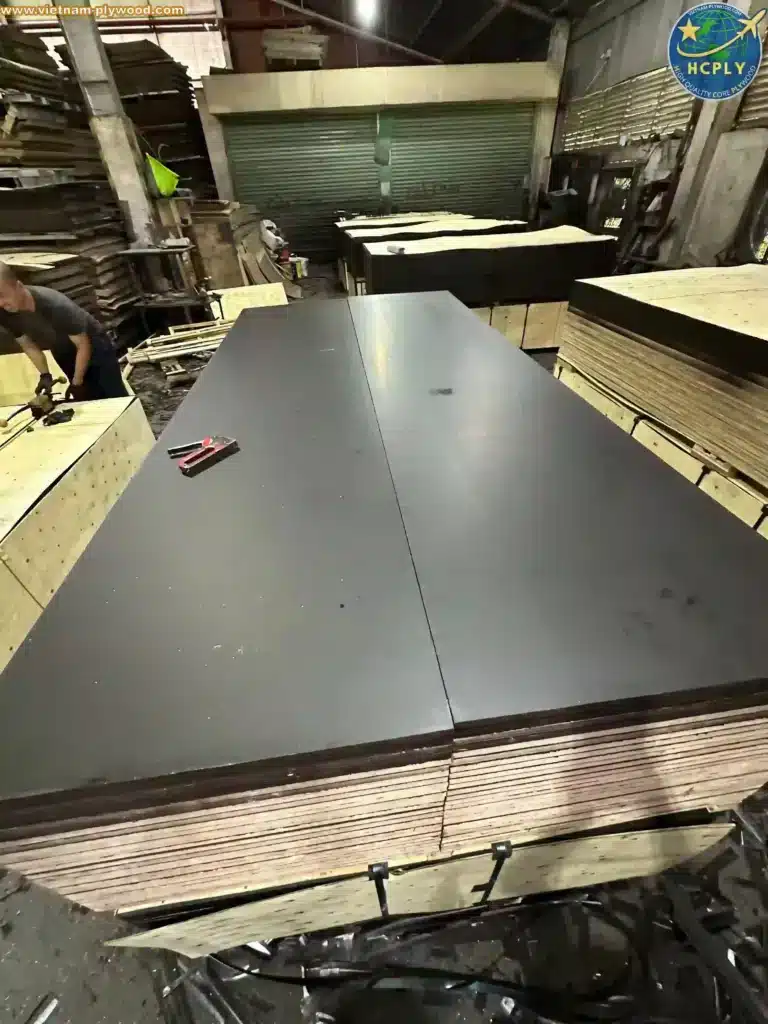

Vietnam’s plywood industry is no longer a rising market — it is now one of the strongest export engines in Asia. Across the world, buyers from the EU, Middle East, LATAM, Canada, and South Asia are increasingly shifting orders from China, Malaysia, and Indonesia to Vietnam because of better pricing stability, faster production, and higher export standards.

And behind this global momentum stand the Top 10 Plywood Exporters in Vietnam, the companies shaping supply chains, stabilizing prices, and delivering millions of cubic meters of plywood every year.

As one of Vietnam’s leading plywood manufacturers and exporters, HCPLY proudly stands among the driving forces of the industry — with strong production capacity, consistent quality, global certifications, and a reputation trusted by importers across Europe, the Middle East, and Latin America.

This guide gives buyers a deep look into Vietnam’s real export landscape — helping you understand which exporters hold true global strength, and why Vietnam will remain a dominant plywood supplier for 2025 and beyond.

1️⃣ Vietnam Plywood Export Performance 2023–2025 — Growth, Volume & Market Momentum

Vietnam’s plywood export sector has transformed dramatically between 2023 and 2025, becoming one of the most competitive supply hubs in Asia. As demand rises across Europe, the Middle East, North America, and Latin America, Plywood Exporters in Vietnam continue strengthening global supply chains with high-quality, cost-effective, and certification-ready products.

From 2023 to 2024, Vietnam’s plywood export volume increased steadily, reaching 2.6–2.8 million m³/year, supported by more than 150 active production facilities and a small group of large-scale exporters who dominate international shipments. In 2025, forecasts show an expected 9–12% growth, driven by EU EUDR compliance, higher demand for construction plywood, and increased substitution away from Chinese suppliers due to anti-dumping duties and rising costs.

Vietnam’s advantage is built on four key pillars:

- Competitive pricing (5–12% lower than China in 2024–2025)

- Stable raw material supply from acacia, eucalyptus, and mixed hardwood cores

- Advanced glue systems meeting CARB/EPA formaldehyde standards

- Fast production speed due to optimized factory clusters in Northern and Central Vietnam

Within this advancing landscape, Plywood Exporters in Vietnam like HCPLY play a crucial role — supplying consistent quality with large production capacity, strict QC, and full global documentation (FSC, CE, CARB, ISO, EUDR). These strengths position Vietnam as a long-term, reliable plywood manufacturing and exporting hub for importers seeking both scale and stability.

Today, Vietnam is no longer a low-cost alternative — it is a strategic global export center trusted by buyers in Italy, Poland, France, Spain, Turkey, UAE, Saudi Arabia, Mexico, Chile, Honduras, and beyond. And at the core of this transformation are the top-tier exporters whose operational strength drives the country’s global competitiveness.

As one of the leading plywood manufacturers, suppliers, and exporters in Vietnam, HCPLY continues delivering high-volume orders with consistent quality, competitive pricing, and proven export strength — helping global buyers secure dependable shipments throughout 2025 and the years ahead.

2️⃣ Key Global Markets Importing Vietnam Plywood (EU, Middle East, LATAM, North America)

As global demand expands, the role of Plywood Exporters in Vietnam has become increasingly strategic — not only supplying competitive products but also supporting buyers across continents with the right specifications, certifications, and logistics flexibility. Between 2023 and 2025, Vietnam’s plywood exports strengthened significantly across four major global regions: Europe, the Middle East, Latin America, and North America.

Each region demands different standards, and only top-tier exporters such as HCPLY can consistently meet these technical, legal, and commercial requirements at scale. Below is a detailed look at how each market imports plywood from Vietnam and why top exporters are gaining long-term dominance.

🇪🇺 2.1 European Union — High Standards, Low Emission, EUDR Compliance

Europe is one of the most demanding markets for Plywood Exporters in Vietnam, requiring strict control over:

- E1/E0/CARB/EPA emission levels

- CE marking & DoP documentation

- FSC® Chain of Custody

- Precise thickness tolerance

- Calibrated surfaces for interior manufacturing

- EUDR traceability with GPS-level origin tracking

Top destinations: Italy, Poland, Germany, France, Spain, Netherlands, Baltic countries.

European buyers select Vietnam primarily for:

- Stable density (580–650+ kg/m³ for commercial plywood)

- Strong bonding for furniture & CNC machining

- Reliable documentation and customs preparation

HCPLY exports high volumes to Europe and maintains full compliance, helping buyers pass audits with zero delays.

🇴🇲 2.2 Middle East — High-Durability Film Faced Plywood for Construction

Countries such as UAE, Saudi Arabia, Qatar, Oman, Kuwait rely heavily on Vietnam for construction-grade plywood. Their priorities include:

- Phenolic WBP glue (48–72h boil test)

- High density (620–700+ kg/m³)

- 8–15 reuse cycles for formwork

- Dynea/AICA film options

- Anti-slip surfaces for scaffolding

Vietnam’s pricing advantage over China is a major factor, making top Plywood Exporters in Vietnam the preferred suppliers for mega construction projects.

HCPLY is recognized as a stable exporter for this region due to consistent density and film quality.

🇺🇸 2.3 North America — CARB/EPA & Precision Plywood

The USA and Canada are increasingly shifting to Vietnam for:

- Furniture-grade plywood

- Carpentry, cabinetry & joinery plywood

- Low-emission CARB/EPA-certified plywood

- Balanced-core construction for CNC machines

Key reasons importers prefer Vietnam:

- Better emissions compliance

- More stable veneer than Southeast Asian competitors

- Faster lead times

- Lower risk of customs delays compared to China

HCPLY supplies commercial and premium plywood to North American buyers seeking long-term consistency.

🇨🇱🇵🇪🇭🇳 2.4 Latin America — Fast-Growing Demand for Film Faced & Commercial Plywood

LATAM is one of the fastest-expanding regions for Plywood Exporters in Vietnam, especially:

- Chile

- Peru

- Honduras

- Dominican Republic

- Colombia

LATAM buyers need:

- Strong film faced plywood for construction

- Competitive pricing

- High bending strength

- Reliable moisture control

- Hard surface film for tropical climates

Vietnam is now replacing China in many LATAM countries due to:

- Better delivery times

- Lower tariff risks

- More stable quality

HCPLY ships large volumes to LATAM with high repeat order rates thanks to consistent formwork performance.

🌏 2.5 Asia-Pacific — Competitive Pricing & Fast Lead Times

Markets such as Korea, Japan, Philippines, Thailand, Malaysia import plywood from Vietnam for:

- Reliable quality at mid-range pricing

- Moisture-stable commercial plywood

- Mixed-core plywood for mass-market furniture

- Fast production cycles

Vietnam’s geographical proximity ensures fast shipments and flexible container planning.

⭐ Why HCPLY Leads Across All Global Markets

HCPLY is one of the few Plywood Exporters in Vietnam with the capability to supply all major market types consistently.

We excel because we provide:

- Market-specific product customization

- Global-standard documentation

- High-volume production capacity

- Stable pricing and year-round supply

- Professional export communication

- Strict QC from veneer to final pallet

This combination makes HCPLY a trusted long-term partner across Europe, Middle East, LATAM, North America, and Asia.

3️⃣ Export Capacity Comparison — Top 10 Plywood Exporters in Vietnam

The real strength of Vietnam’s plywood industry lies in its export capacity — the ability to produce high volumes consistently, maintain strict QC, and ship globally without interruption. This is where the difference between ordinary suppliers and true Plywood Exporters in Vietnam becomes clear. Only a handful of large-scale exporters can meet the demanding expectations of European importers, Middle Eastern contractors, North American distributors, and Latin American construction groups.

Between 2023 and 2025, Vietnam recorded one of the strongest plywood export expansions in Asia. Total national plywood output reached 5.2–5.5 million m³/year, of which approximately 2.6–2.8 million m³ were exported. However, over 70% of this volume is concentrated among the Top 10 Plywood Exporters in Vietnam — the companies with real production power, global compliance, and established shipping networks.

🔹 3.1 Production Capacity Breakdown Among Top Exporters

The leading Plywood Exporters in Vietnam typically operate with:

- 10–25 hot press lines per factory cluster

- Monthly output of 150–350 containers for film faced plywood & commercial plywood

- Warehouse storage of 5,000–12,000 m³ veneer

- In-house glue production for MR, Melamine, and Phenolic WBP

- Multiple veneer peeling & drying stations ensuring stable raw material supply

Factories with this scale dominate export markets because they deliver consistent quality even during peak season.

🔹 3.2 Why Export Capacity Matters to Global Buyers

High-capacity exporters prevent the common risks that buyers face in Asia:

- shipment delays

- inconsistent moisture levels

- unstable density

- glue quality fluctuations

- outsourcing to smaller workshops (big industry problem)

Top Plywood Exporters in Vietnam operate vertically integrated systems — veneer, core layup, hot pressing, calibration, sanding, and packing are all monitored under strict QC. This ensures shipments remain stable throughout the year.

🔹 3.3 HCPLY’s Export Capacity — A Leading Force in Vietnam

As one of the most trusted Plywood Exporters in Vietnam, HCPLY operates with:

- 20–40 containers/month export capacity

- Dedicated film faced plywood production for EU, Middle East & LATAM

- Commercial plywood lines for furniture, cabinetry & CNC

- FSC, CE, CARB/EPA documentation for global markets

- 7-step QC system with moisture & density reporting

- 100% factory-direct production (no outsourcing)

HCPLY’s capacity advantages give international buyers:

- shorter lead times

- stable volume even during seasonal peaks

- consistent quality across all shipments

- dependable yearly sourcing plans

These strengths position HCPLY among the top-performing Plywood Exporters in Vietnam for 2025 and beyond.

🔹 3.4 Comparative Capacity of Vietnam vs. China & Indonesia

Compared with regional competitors:

- China has larger total output but higher price fluctuations and stricter anti-dumping risks

- Indonesia exports premium hardwood plywood but at much higher cost

- Malaysia has declining veneer supply

- Vietnam offers the best balance of cost, compliance, and volume consistency

This is why global distributors are increasingly relying on Vietnam — and especially on reliable exporters like HCPLY — for long-term plywood sourcing.

By delivering strong monthly capacity, global-standard QC, and export documentation suitable for all markets, HCPLY continues to stand out among the leading Plywood Exporters in Vietnam, ensuring buyers receive the stability and performance needed in 2025 and beyond.

4️⃣ Certifications, Compliance & Export Legitimacy (FSC, CE, CARB, EPA, EUDR)

Global import markets have become significantly stricter from 2023 to 2025, forcing every exporter to meet higher compliance, documentation accuracy, and chain-of-custody requirements. This is where professional Plywood Exporters in Vietnam differentiate themselves from ordinary factories. Only top-tier exporters can provide full certification systems covering Europe, North America, the Middle East, and Latin America.

In an era of tightening regulations — from EUDR to CARB Phase II — certifications are no longer “extra documents.” They are now the foundation of export legitimacy. Buyers worldwide increasingly choose Plywood Exporters in Vietnam that can guarantee legal origin, low emissions, and stable documentation quality across shipments.

🔹 4.1 FSC® Chain of Custody (CoC)

FSC remains the most influential certification for sustainable timber trade.

Top Plywood Exporters in Vietnam provide:

- FSC 100%, FSC MIX, FSC Controlled Wood

- Verified supply chain from forest → veneer → plywood

- Traceable batch codes

- Yearly audit reports

- FSC claim clearly printed on packaging

These documents are essential for European and North American importers who require verified legal origin.

HCPLY maintains full FSC® compliance, ensuring buyers meet sustainability standards effortlessly.

🔹 4.2 CE Marking & DoP (Declaration of Performance)

Required for plywood sold in the EU market, CE marking proves that the product meets:

- Mechanical performance

- Bonding strength

- Emission level

- Dimensional consistency

- Reaction-to-fire classification

Leading Plywood Exporters in Vietnam provide CE + DoP customized by product type (poplar core, eucalyptus core, full hardwood core, etc.).

HCPLY issues CE DoP files for each buyer, ensuring smooth customs clearance and zero compliance problems.

🔹 4.3 CARB Phase II & EPA TSCA Title VI

For USA & Canada, emissions compliance is mandatory.

CARB/EPA documents verify:

- Ultra-low formaldehyde emissions

- Verified resin systems

- Monthly lab test results

Top Plywood Exporters in Vietnam operate using MR/Melamine/Phenolic resins that exceed CARB requirements.

HCPLY provides batch-specific lab test reports and EPA compliance forms with every shipment.

🔹 4.4 ISO Certifications (ISO 9001, ISO 14001, ISO 45001)

Global importers increasingly require:

- ISO 9001: Quality management

- ISO 14001: Environmental management

- ISO 45001: Worker safety

These verify that the factory meets international operational standards — not just product standards.

HCPLY holds a complete ISO management system that ensures continuous quality control across every container.

🔹 4.5 EUDR Compliance — The New Mandatory Standard (2024–2025)

EUDR (EU Deforestation Regulation) is the most impactful regulation for plywood imports into Europe.

It requires:

- Tree species declaration

- Country + province origin

- GPS coordinates of wood origin

- Risk-mitigation documentation

- Operator due diligence statements

- Timestamped supply chain traceability

Only the most professional Plywood Exporters in Vietnam can meet these requirements.

HCPLY provides:

- Verified origin documentation

- GPS-based supply chain mapping

- EUDR-compliant due diligence files

- Batch-level transparency

This makes HCPLY a top-choice exporter for EU distributors preparing for long-term EUDR enforcement.

🔹 4.6 Halal Certification (Middle East Market)

Some Middle Eastern buyers require Halal certification for construction materials used in government projects.

HCPLY supports Halal documentation for qualifying plywood lines.

🔹 4.7 Why Certifications Determine True Export Strength

Certifications reflect more than legality — they reflect a company’s commitment to global responsibility and long-term export capability. Any exporter can produce plywood, but only top Plywood Exporters in Vietnam can consistently meet:

- International audits

- Environmental compliance

- Safety regulations

- Full documentation

- Buyer-side verification requests

This is exactly where HCPLY leads the industry.

With full FSC, CE, CARB/EPA, ISO, and EUDR documentation systems, HCPLY stands among the most reliable and compliant Plywood Exporters in Vietnam, ensuring buyers face zero risks and maximum trust when importing plywood from Vietnam.

5️⃣ Raw Materials & Core Veneer Quality — Hardwood, Acacia, Eucalyptus, Mixed Core

The foundation of every plywood panel is the core veneer, and this is one of the strongest competitive advantages of Vietnam. Top-tier Plywood Exporters in Vietnam are able to supply consistent, high-strength veneer structures because Vietnam has a unique combination of raw materials, veneer milling capacity, and stable forest plantations.

Between 2023 and 2025, global buyers increasingly shifted orders to exporters who can guarantee veneer quality — moisture stability, uniform thickness, clean jointing, and accurate layer counts — all of which define final plywood durability. This is why the best-performing Plywood Exporters in Vietnam invest heavily in veneer grading and in-house production systems.

Below is a detailed breakdown of the veneer types that drive Vietnam’s export competitiveness and why HCPLY excels in each segment.

🔹 5.1 Acacia Core — Vietnam’s Signature Strength

Acacia is one of Vietnam’s most widely used raw materials, known for:

- Excellent bending strength

- High internal bonding

- Stable density (600–680 kg/m³)

- Strong resistance to deformation

- Smooth layup performance

Acacia-based plywood is preferred by buyers in:

- Middle East (construction formwork)

- Latin America (scaffolding, concrete work)

- EU furniture manufacturers needing higher strength levels

Leading Plywood Exporters in Vietnam source acacia veneer from large, controlled plantations with stable annual output.

HCPLY uses calibrated acacia veneer for reliable bonding and high mechanical strength across all product lines.

🔹 5.2 Eucalyptus Core — High Density & Excellent Compression

Eucalyptus veneer delivers:

- Higher density (650–720 kg/m³)

- Better screw-holding power

- Greater surface hardness

- Superior vertical compression strength

This veneer type is ideal for:

- High-load construction

- Heavy-duty film faced plywood

- CNC machining for furniture components

Top Plywood Exporters in Vietnam blend eucalyptus layers strategically to achieve consistent panel stiffness.

HCPLY integrates eucalyptus veneer in both commercial and film faced plywood for stronger internal structure.

🔹 5.3 Mixed Hardwood Core — Balanced, Cost-Effective, Export-Friendly

Vietnam’s hardwood veneer mix (keo, styrax, hopea odorata, tropical hardwoods) provides:

- Balanced density

- Stable moisture content

- Uniform bonding

- Cost-effective production

This option is popular in:

- Africa (general construction)

- Middle East (non-structural use)

- Southeast Asia (furniture frame production)

Top Plywood Exporters in Vietnam rely on mixed hardwood for its flexibility and affordability.

HCPLY’s mixed-core plywood maintains consistent QC, making it suitable for budget-conscious markets.

🔹 5.4 Poplar & Imported Veneer — Light Weight for European Needs

Poplar veneer (imported or locally processed) is preferred for:

- Lightweight furniture

- Interior paneling

- Laminating and veneering

- CNC-friendly applications

European buyers often require:

- Smooth surface

- Calibrated thickness

- Clean joint lines

HCPLY supplies poplar-core plywood for EU clients, ensuring low emissions and exceptional stability during lamination.

🔹 5.5 Jointing & Veneer Quality Control — The Real Differentiator

What separates ordinary suppliers from real Plywood Exporters in Vietnam is veneer accuracy.

Key QC standards include:

- Moisture: 8–12%

- Thickness tolerance: ±0.1–0.2 mm

- Surface cleanness: No knots, holes, or patches

- Jointing: Straight-line or finger-joint depending on application

- Layer count: Precisely matched to buyer spec

- Density mapping for each pallet

HCPLY uses a 7-step veneer QC system covering peeling → drying → sorting → grading → jointing → layup → pressing.

🔹 5.6 Why HCPLY’s Veneer Structure Performs Better

As one of the leading Plywood Exporters in Vietnam, HCPLY ensures superior veneer quality through:

- In-house veneer production

- Laser-guided calibration

- Stable supply from multiple plantations

- Moisture meters at every production stage

- Dedicated veneer storage to prevent warping

- Density testing for each batch

This allows HCPLY to deliver plywood with:

- Superior bonding

- Higher mechanical strength

- Longer lifespan

- Better performance under extreme humidity

- Consistent quality across all global shipments

Vietnam’s veneer advantage is one of the main reasons global importers increasingly choose strong, certified, high-capacity Plywood Exporters in Vietnam like HCPLY — the quality begins from the core.

6️⃣ Glue Systems & Bonding Strength — MR, Melamine, WBP Phenolic

Among all technical factors that define plywood durability, the glue system is the single most important, and this is a core strength of top-performing Plywood Exporters in Vietnam. Between 2023 and 2025, global buyers have become increasingly strict about bonding strength, boil-test results, emissions compliance, and long-term panel stability — especially in markets such as the EU, Middle East, LATAM, and North America.

Vietnam’s leading exporters have invested heavily in in-house glue production lines, automated mixing systems, and controlled resin quality. This is why the strongest and most consistent plywood from Asia is now produced in Vietnam, not China or Malaysia. Below is a deep breakdown of the glue systems used by top Plywood Exporters in Vietnam, and why HCPLY delivers superior bonding performance across all product categories.

🔹 6.1 MR Glue — Interior Use with Stable Bonding

MR (Moisture Resistant) glue is designed for:

- indoor applications

- furniture manufacturing

- cabinetry & interior joinery

- dry environments

High-quality MR glue ensures:

- low emissions

- stable bonding at room temperature

- clean sanding surface

- smooth finishing

Top Plywood Exporters in Vietnam use MR glue that meets E1/E0/CARB standards, supported by regular lab tests.

HCPLY applies MR glue with strict viscosity and solids-content control to ensure consistent bonding strength in every panel.

🔹 6.2 Melamine Glue — Stronger Bonding & Low Emissions

Melamine-added Urea Formaldehyde (MUF) improves:

- bonding strength

- moisture resistance

- long-term stability

- lower emissions (CARB/EPA compliant)

Melamine plywood is preferred in:

- high-end furniture

- caravan & van interior paneling

- laminate & veneer pressing applications

- markets requiring low-formaldehyde products

Top Plywood Exporters in Vietnam — including HCPLY — use melamine systems with 8–12% melamine content, optimized for stronger internal bonding.

🔹 6.3 Phenolic WBP Glue — The Industry Standard for Film Faced Plywood

Phenolic glue (WBP – Weather & Boil Proof) is the strongest glue system available and the backbone of construction plywood exported from Vietnam.

Key performance points:

- 48–72 hour boil test durability

- weatherproof bonding

- high heat & moisture resistance

- suitable for harsh outdoor use

- stable under repeated reuse cycles

This glue is essential for:

- film faced plywood

- formwork plywood

- marine-use panels

- anti-slip boards

Only the leading Plywood Exporters in Vietnam have the machinery and QC to ensure real WBP bonding — many smaller factories fail the boil test due to poor resin quality.

HCPLY uses phenolic glue ≥ 15% solids content, delivering:

- higher reuse cycles

- stronger cross-bonding

- stable density

- zero delamination

This is one of the reasons HCPLY is a top choice for Middle East and LATAM construction buyers.

🔹 6.4 Glue Quality Control — A Critical Exporter Advantage

Professional exporters conduct strict QC over glue systems:

- viscosity measurement for every batch

- solids content verification

- resin-to-hardener mixing ratios

- hot-press temperature calibration

- pressure curve monitoring

- bonding strength tests

- post-press delamination inspection

The best Plywood Exporters in Vietnam maintain complete traceability for all glue systems used in production.

HCPLY applies a 7-step glue QC protocol to ensure every container ships with stable and proven bonding performance.

🔹 6.5 Why HCPLY’s Glue Systems Outperform Market Standards

HCPLY’s in-house glue production ensures:

- consistent resin formulation

- zero outsourcing

- stable quality across seasons

- accurate curing

- stronger core bonding

- better surface film adhesion

This allows HCPLY to supply plywood with:

- superior boil test results

- longer lifespan in construction

- higher bending & shear strength

- exceptional dimensional stability

🔹 6.6 Summary — Glue Systems Define Export Quality

The difference between a standard supplier and a top Plywood Exporter in Vietnam is the ability to guarantee bonding performance under all conditions — heat, humidity, pressure, and long-term use.

This is exactly where HCPLY leads the market.

With MR, Melamine, and Phenolic WBP glue systems fully optimized for global export requirements, HCPLY ensures buyers receive plywood that performs consistently in all applications — from furniture production to large-scale construction projects worldwide.

7️⃣ Film Faced & Commercial Plywood Specialization Among Vietnam Exporters

One of the strongest competitive advantages of Plywood Exporters in Vietnam is their ability to specialize across two major product lines — Film Faced Plywood (FFP) and Commercial Plywood (CP). These categories represent more than 80% of Vietnam’s total plywood export volume from 2023 to 2025. Each product line serves different global markets, requiring different veneer structures, glue systems, and surface finishing techniques. Only top exporters like HCPLY possess the technical depth, production capacity, and certification systems to excel in both.

This specialization is crucial because global buyers increasingly demand market-specific plywood — stronger film faced boards for construction, cleaner commercial plywood for furniture, and calibrated surfaces for CNC applications. Below is a comprehensive breakdown of how leading Plywood Exporters in Vietnam dominate these two sectors.

🔹 7.1 Film Faced Plywood — Vietnam’s Global Export Powerhouse

Film Faced Plywood accounts for over 60% of Vietnam’s plywood exports, driven by strong demand from:

- Middle East (UAE, Saudi Arabia, Qatar, Oman)

- LATAM (Chile, Peru, Honduras)

- Asia-Pacific (Korea, Thailand, Philippines)

- Eastern Europe (Poland, Romania, Bulgaria)

Top Plywood Exporters in Vietnam meet the market’s high structural requirements through:

Core Strength

- Eucalyptus core (650–720 kg/m³ density)

- Acacia core (high bonding strength)

- Mixed hardwood core (cost-effective, stable)

Glue Systems

- WBP phenolic glue (48–72h boil test)

- High melamine content for hybrid mix

- Heat-resistant curing to prevent delamination

Surface Film

- Dynea brown/black film

- AICA brown film

- Anti-slip wire-mesh film

- UV-resistant options

Reuse Cycle Performance

- Standard grade: 5–8 times

- High-performance phenolic grade: 10–15 times

- Premium AICA/Dynea: 15–20 cycles (used in UAE mega projects)

Leading Film Faced Plywood Exporters in Vietnam, including HCPLY, supply customized density, glue, and film solutions based on project specifications — something smaller factories cannot consistently provide.

🔹 7.2 Commercial Plywood — The Backbone for Furniture & Interior Markets

Commercial plywood is essential for markets requiring clean surfaces, low emissions, and stable calibration. Key importing regions include:

- EU (Italy, Poland, Germany, Spain)

- North America (USA, Canada)

- Asia-Pacific (Japan, Korea, Malaysia)

Core strengths used by top Plywood Exporters in Vietnam include:

- Poplar core (lightweight, smooth)

- Acacia core (strong, durable)

- Eucalyptus core (high density)

- Mixed hardwood core (balanced cost–performance)

Applications

- Furniture production

- Cabinets & wardrobes

- Van interiors

- CNC routing

- Lamination & veneer pressing

- Interior partition & paneling

Technical Requirements

- CARB/EPA low emissions

- E1/E0/EO formaldehyde levels

- Calibrated surface (±0.2 mm tolerance)

- Clean jointing and uniform veneer thickness

HCPLY excels in commercial plywood exports due to its:

- laser-calibrated sanding lines

- clean veneer preparation

- consistent moisture control (8–12%)

- factory-direct production

This is why HCPLY is a preferred supplier for EU and North American distributors seeking stable quality.

🔹 7.3 Why Vietnam Excels in Both FFP & Commercial Plywood

Top Plywood Exporters in Vietnam outperform regional competitors because they offer:

- Dual specialization (construction-grade + furniture-grade)

- Flexible customization per destination market

- Large capacity clusters enabling stable monthly export volume

- In-house glue production ensuring consistent bonding

- FSC, CE, CARB/EPA, ISO, EUDR documentation

- Fast lead time due to optimized production clusters

- Competitive pricing vs China & Indonesia

This dual-competency allows Vietnam to dominate both construction and furniture plywood markets simultaneously.

🔹 7.4 HCPLY — A Leader in Both Specializations

HCPLY stands out among the top Plywood Exporters in Vietnam because we master both categories:

Film Faced Plywood (FFP):

- Phenolic WBP glue

- AICA/Dynea film

- High-density eucalyptus & acacia core

- 10–20 reuse cycles

- Perfect for Middle East & LATAM markets

Commercial Plywood (CP):

- CARB/EPA compliant

- Poplar/acacia/eucalyptus structure

- Clean surface and calibrated thickness

- Ideal for furniture, interiors & CNC

Our production systems allow HCPLY to switch quickly between product lines while maintaining stable quality, fast delivery times, and full export compliance.

Summary — Specialization Defines Export Leadership

In 2025 and beyond, buyers worldwide prefer exporters who can supply both FFP and CP in high volume, with identical quality across containers and across seasons.

This specialization is the hallmark of elite Plywood Exporters in Vietnam, and HCPLY is among the strongest — delivering both construction-grade and furniture-grade plywood with precision, scale, and reliability that global buyers depend on.

8️⃣ Price Comparison & Cost Structure — What Affects FOB/CIF Pricing?

Across 2023–2025, one of the biggest reasons global buyers shifted to Vietnam is the transparent and competitive pricing structure offered by leading Plywood Exporters in Vietnam. Unlike other markets where prices fluctuate heavily due to inconsistent raw materials or unstable supply chains, Vietnam provides a more predictable cost framework supported by strong veneer supply, optimized factory clusters, and efficient export logistics.

However, plywood pricing is never random. It is shaped by multiple technical and operational factors — veneer type, density, glue system, film brand, calibration processes, certifications, and even seasonal moisture conditions. The most experienced buyers analyze these variables carefully to avoid overpaying or receiving underperforming material. Below is a deeply detailed breakdown of everything that influences price among the top Plywood Exporters in Vietnam, along with HCPLY’s strategic advantages.

🔹 8.1 Core Veneer Type — The Largest Cost Component

Veneer contributes 60–70% of total panel cost.

Different veneer structures lead to different pricing levels:

| Core Type | Density | Durability | Price Level | Used For |

|---|---|---|---|---|

| Eucalyptus | 650–720 kg/m³ | Very High | High | Construction, FFP |

| Acacia | 600–680 kg/m³ | High | Mid–High | Construction & furniture |

| Mixed hardwood | 550–650 kg/m³ | Medium | Mid | General markets |

| Poplar | 450–520 kg/m³ | Low–Medium | Low | Furniture, CNC |

Top Plywood Exporters in Vietnam maintain strict veneer grading systems to stabilize costs while ensuring consistent mechanical performance.

HCPLY uses in-house veneer production for stable pricing even during peak season.

🔹 8.2 Glue System — Phenolic WBP vs Melamine vs MR

Glue quality directly affects price:

| Glue Type | Boil Test | Price Impact | Typical Application |

|---|---|---|---|

| Phenolic WBP | 48–72h | High | Film faced plywood |

| Melamine MUF | 6–12h | Mid | Furniture & laminated boards |

| MR | Non-boiling | Low | Interior use |

Phenolic resin is the most expensive, often accounting for 20–30% of the added value in Film Faced Plywood.

Leading Plywood Exporters in Vietnam, such as HCPLY, use high-solid-content phenolic glue (≥15%) for superior performance — ensuring higher durability for buyers in construction markets.

🔹 8.3 Surface Film — Brand Matters

Film choice significantly impacts pricing:

- AICA (Japan) — premium, longest durability → +$1.5 to $2.5/sheet

- Dynea (Finland/Asia) — high-quality phenolic → +$1 to $1.8/sheet

- Local film — cheaper → baseline price

Film selection directly changes the number of reuse cycles:

| Film Type | Expected Reuse Cycles |

|---|---|

| AICA | 15–20 cycles |

| Dynea | 10–15 cycles |

| Local film | 5–8 cycles |

Top Plywood Exporters in Vietnam choose film based on regional project requirements.

HCPLY provides all three options depending on budget and performance demands.

🔹 8.4 Thickness, Density & Layer Count

Higher thickness and density increase cost due to:

- More veneer layers

- Longer hot-pressing time

- Higher glue consumption

- Increased labor time

Typical cost differences per thickness:

| Thickness | Cost Impact |

|---|---|

| 12mm | Baseline |

| 15mm | +$0.6–$0.9/sheet |

| 18mm | +$1–$1.6/sheet |

Density calibration also adds cost:

- Standard density → no extra cost

- High density (≥680 kg/m³) → +$0.8–$1.4/sheet

HCPLY offers fully calibrated plywood for European, Middle Eastern, and LATAM buyers.

🔹 8.5 Certification & Documentation Costs

Importing regions like EU, USA, and Canada require:

- FSC

- CE + DoP

- CARB/EPA

- EUDR compliance

- ISO documentation

- Legal origin verification

Each certification adds administrative and audit costs.

Top Plywood Exporters in Vietnam include these charges transparently in quotations.

HCPLY provides full documentation with no hidden costs — a key value for global buyers.

🔹 8.6 Seasonal Effects on Pricing

Seasonal factors influence veneer availability:

Rainy Season (Jun–Sep):

- Higher veneer moisture

- Slower drying

- Higher reject rates

→ Price increases 3–6%

Dry Season (Oct–Apr):

- Lower moisture

- Higher veneer yield

→ More stable pricing

Professional Plywood Exporters in Vietnam adjust production capacity to minimize seasonal fluctuations.

HCPLY maintains buffer veneer stock to keep buyer prices stable year-round.

🔹 8.7 FOB vs CIF Pricing Differences

FOB Prices depend on:

- veneer cost

- glue

- density

- certifications

- film quality

- labor

- QC

- packing materials

CIF Prices add:

- freight rates

- container availability

- seasonal shipping surcharges

Freight to key markets (2024–2025 average):

- EU: $2,100–$2,600 per 40HC

- Middle East: $1,200–$1,600

- LATAM: $3,500–$4,800

- North America: $2,800–$3,400

HCPLY provides both FOB and CIF options depending on buyer preference.

🔹 8.8 Why HCPLY’s Prices Are More Stable & Competitive

HCPLY maintains one of the most optimized price structures among all Plywood Exporters in Vietnam because:

- In-house veneer production reduces market risk

- Glue production is fully internal

- Vertical integration lowers outsourcing costs

- Strong supplier relationships stabilize raw material pricing

- Year-round veneer storage ensures seasonal stability

- Efficient factory clusters reduce waste and labor costs

- High production volume reduces per-unit cost

This allows HCPLY to offer:

- more competitive pricing

- stronger quality consistency

- stable delivery times

- tailored solutions for every market segment

Summary — Price Reflects Structure, Not Guesswork

Understanding plywood pricing requires analyzing veneer, glue, film, density, certifications, and logistics — not just the final quotation.

This comprehensive price transparency is why top buyers around the world choose HCPLY and why HCPLY stands among the strongest, most trusted Plywood Exporters in Vietnam for 2025 and beyond.

9️⃣ Common Buyer Problems When Importing From Vietnam & How Top Exporters Solve Them

Even though Vietnam has become one of the strongest global supply hubs, importers still face several recurring issues when dealing with less-experienced factories. These problems are not caused by Vietnam as a market — they are caused by inconsistent production standards among small workshops that lack export experience. This is why buyers increasingly prefer working with established, high-capacity Plywood Exporters in Vietnam, who follow strict global standards and deliver predictable, stable results.

Below is the most comprehensive breakdown of the real issues international buyers commonly face — and exactly how top exporters, including HCPLY, solve every one of them with transparency, strong QC systems, and factory-direct control.

🔹 9.1 Inconsistent Moisture Levels (The Most Common Problem)

Buyer Problem:

Many factories fail to control moisture during rainy season (Jun–Sep), leading to:

- warping

- bending

- delamination

- weight fluctuation

- mold growth during shipping

How Top Exporters Solve It:

Leading Plywood Exporters in Vietnam use:

- kiln drying systems

- strict 8–12% moisture standard

- digital moisture meters for every pallet

- temperature-controlled storage

- pre-shipment moisture reports

HCPLY Advantage:

HCPLY performs triple moisture checks:

→ veneer stage → core layup → finished plywood → packing report.

🔹 9.2 Density Inconsistency & Core Gaps

Buyer Problem:

Some suppliers cut costs by reducing density or leaving gaps between veneer layers.

This leads to:

- low bending strength

- weak bonding

- poor CNC machining results

- higher failure in construction

How Top Exporters Solve It:

Top Plywood Exporters in Vietnam maintain:

- calibrated veneer thickness

- strict layer count control

- density testing for each batch

- anti-gap inspection using spot-light systems

HCPLY Advantage:

HCPLY maintains 620–720 kg/m³ for construction plywood and 580–650 kg/m³ for commercial-grade boards with zero tolerance for internal gaps.

🔹 9.3 Glue Quality Fluctuation

Buyer Problem:

Some factories use different glue quality in peak season to reduce costs, causing:

- boiling test failure

- delamination

- reduced reuse cycles for film faced plywood

How Top Exporters Solve It:

Professional exporters use:

- in-house glue production

- ISO-controlled mixing ratios

- solids-content verification

- standardized pressing cycles

- batch-specific glue QC reports

HCPLY Advantage:

HCPLY uses ≥15% phenolic solids for WBP and 8–12% melamine for MUF, ensuring stable, export-grade bonding every month of the year.

🔹 9.4 Outsourcing to Smaller Workshops (Hidden Risk)

Buyer Problem:

This is the biggest hidden danger in Vietnam.

Some exporters outsource 30–70% of production during peak season, causing:

- inconsistent quality

- different veneer sources

- no documentation traceability

- shipment delays

- customs problems

How Top Exporters Solve It:

Reliable Plywood Exporters in Vietnam operate factory-direct systems with:

- no outsourcing

- dedicated veneer peeling lines

- in-house layup and hot pressing

- strict QC checkpoints

HCPLY Advantage:

HCPLY is 100% factory-direct, fully controlling veneer, glue, pressing, calibration, and packing.

🔹 9.5 Thickness Tolerance Issues

Buyer Problem:

Inconsistent thickness leads to:

- CNC inaccuracy

- uneven laminating

- customer complaints

- rejected shipments

How Top Exporters Solve It:

Professional exporters ensure:

- laser-calibrated sanding

- ±0.2 mm tolerance

- calibrated finishing for EU & North America

- full thickness report for each batch

HCPLY Advantage:

HCPLY uses automated Italian sanding lines to ensure precise thickness for every container.

🔹 9.6 Poor Film Quality in FFP

Buyer Problem:

Cheap film (local production) results in:

- easy surface cracking

- low reuse cycles

- poor concrete finish

- short lifespan

How Top Exporters Solve It:

Top exporters use:

- AICA film

- Dynea film

- UV-resistant films

- anti-slip wire-mesh film variants

HCPLY Advantage:

HCPLY supplies AICA/Dynea for premium orders and ensures 10–20 reuse cycles depending on grade.

🔹 9.7 Delays in Lead Time

Buyer Problem:

Small factories struggle with:

- weak planning

- lack of veneer buffer

- rainy-season moisture delays

- labor shortages

- port congestion

How Top Exporters Solve It:

Leading Plywood Exporters in Vietnam maintain:

- 5,000–12,000 m³ veneer storage

- multi-line production

- dedicated export schedules

- coordinated shipping plans

HCPLY Advantage:

HCPLY delivers 20–40 containers/month with consistent lead time, even during peak season.

🔹 9.8 Incomplete Export Documentation

Buyer Problem:

Incorrect paperwork causes:

- customs delays

- port fines

- shipment holds

- buyer-side complaints

How Top Exporters Solve It:

Professional exporters provide:

- FSC

- CE + DoP

- CARB/EPA

- ISO

- EUDR provenance files

- HS code documentation

- packing lists & moisture/density reports

HCPLY Advantage:

HCPLY delivers full documentation sets for EU, Middle East, LATAM, and North America.

🔹 9.9 Communication Gaps with Factory Staff

Buyer Problem:

Buyers often struggle when communicating with:

- non-English-speaking factory workers

- inexperienced sales teams

- people who do not understand export requirements

How Top Exporters Solve It:

Top exporters employ:

- professional export teams

- technical support staff

- English-speaking QC staff

- clear reporting systems

HCPLY Advantage:

HCPLY’s export team provides:

- fast response times

- photo/video QC documentation

- shipment tracking

- problem-solving support

🔹 9.10 Why Buyers Trust HCPLY Over Others

HCPLY solves all major buyer problems by operating as one of the most reliable Plywood Exporters in Vietnam:

- factory-direct production

- stable veneer & glue quality

- strong QC systems

- certified documentation

- export-trained communication

- high monthly capacity

- competitive, transparent pricing

This is why HCPLY maintains one of the highest repeat-order rates in EU, Middle East, LATAM, and North America — delivering stable quality and trusted service year after year.

🔟 Why HCPLY Is a Leading Plywood Exporter in Vietnam — Scale, Consistency & Global Trust

Among all Plywood Exporters in Vietnam, only a few possess the scale, technical capability, and global compliance systems required to supply demanding markets such as the EU, USA, Canada, Middle East, and LATAM. HCPLY stands firmly in this top tier — not because of marketing claims, but because of measurable production power, factory-direct control, international certifications, and a proven track record of repeat buyers across continents.

Below is the most detailed and authoritative breakdown of why HCPLY is recognized as one of the strongest Plywood Exporters in Vietnam, consistently outperforming competitors in quality, stability, capacity, and export professionalism.

🔹 10.1 Large-Scale Production Capacity Backed by Vietnam’s Strongest Veneer Supply

HCPLY operates in one of Vietnam’s most concentrated plywood production zones, giving access to:

- massive eucalyptus & acacia plantations

- large veneer mills

- fast supply replenishment

- optimized logistics

Key capacity indicators:

- 20–40 containers per month (FFP + Commercial)

- 24/7 production schedule during peak season

- 3 hot-press lines + automated sanding lines

- 5,000–12,000 m³ veneer storage

This enables HCPLY to guarantee stable volume even during high-demand periods when other suppliers struggle.

🔹 10.2 Zero-Outsourcing Policy — 100% Factory-Controlled Production

Many suppliers in Vietnam outsource 30–70% of production.

HCPLY does not outsource at any stage.

Full in-house control includes:

- veneer peeling

- veneer drying

- veneer grading

- core layup

- hot pressing

- sanding calibration

- glue production

- final QC & packing

This is one of the main reasons HCPLY is considered among the most reliable Plywood Exporters in Vietnam — consistent quality across every container, every month.

🔹 10.3 Strongest QC System Among Vietnam Exporters

HCPLY maintains a multi-layer QC system:

Veneer QC

- moisture 8–12%

- density mapping

- clean jointing

- calibrated thickness

Glue QC

- solids-content measurement

- viscosity & curing checks

- batch-based testing

Pressing QC

- pressure & temperature monitoring

- delamination checks

- thickness tolerance verification

Final QC

- pallet-weight consistency

- surface inspection

- edge bonding review

- moisture re-check before packing

This level of control is why HCPLY consistently ranks among top-grade Plywood Exporters in Vietnam for demanding buyers.

🔹 10.4 Full Export Documentation — Zero Customs Issues

HCPLY supplies complete, buyer-ready documentation:

- FSC 100% / MIX / CW

- CE + DoP

- CARB/EPA

- EUDR compliance

- ISO 9001 / 14001 / 45001

- Packing list + moisture report

- HS code accuracy

- Certificate of Origin

- Fumigation certificate (where required)

This eliminates delays, fines, and customs rejections — a common issue with weaker exporters.

🔹 10.5 Global Market Specialization

HCPLY exports to all major global regions:

EU Market

- Italy, Poland, Germany, France, Spain

- strict EUDR & CE requirements

Middle East

- UAE, Qatar, Saudi Arabia, Oman

- high-strength formwork plywood

LATAM

- Chile, Peru, Honduras, Dominican Republic

- heavy construction & scaffolding

North America

- USA, Canada

- CARB/EPA compliance

Asia-Pacific

- Korea, Japan, Thailand, Philippines

This global footprint reinforces HCPLY’s standing among top Plywood Exporters in Vietnam, proving capability across diverse requirements.

🔹 10.6 AICA / Dynea Film + Premium Phenolic Glue Expertise

HCPLY is one of the very few exporters with verified experience in:

- AICA Japanese film

- Dynea phenolic film

- ≥15% phenolic solids-content glue

- 10–20 reuse cycle film faced plywood

This makes HCPLY a preferred supplier for government projects and high-spec construction buyers.

🔹 10.7 Competitive FOB/CIF Pricing Through Vertical Integration

HCPLY achieves lower production cost through:

- in-house veneer

- in-house glue

- zero outsourcing

- optimized pressing cycles

- efficient labor allocation

- minimized waste management

This allows HCPLY to offer aggressive pricing while maintaining top-tier quality — a combination rarely achieved by ordinary suppliers.

🔹 10.8 High Buyer Repeat Rate — The Ultimate Performance Indicator

Long-term buyers from:

- EU

- Middle East

- LATAM

- USA & Canada

continue to reorder from HCPLY because of:

- stable quality

- strong communication

- problem-free documentation

- reliable shipping schedules

This repeat rate is one of the clearest signs that HCPLY is a leading Plywood Exporter in Vietnam, trusted worldwide.

🔹 10.9 Fast Response, Professional Export Communication

HCPLY provides:

- real-time production updates

- detailed QC photos & videos

- container loading reports

- moisture & density test files

- fast quoting (1–2 hours)

In global trade, communication speed is a competitive weapon — and HCPLY treats it as such.

🔹 10.10 Final Proof — HCPLY’s Reputation as a Top Plywood Exporter in Vietnam

When comparing Vietnam’s export landscape, HCPLY consistently appears at the top due to:

- high production capacity

- strict QC standards

- full compliance systems

- technical expertise

- competitive pricing

- global reliability

HCPLY is not only a Plywood Exporter in Vietnam — it is one of the country’s most dependable, professional, and long-term partners for global plywood importers seeking performance, stability, and supply security.

⭐ Final Closing — The Global Market Chooses Vietnam, and Vietnam Chooses HCPLY

As global demand for reliable, high-performance plywood continues to rise, importers are becoming more selective than ever. They no longer search for the cheapest offer — they search for long-term partners, stable production, real factories, international compliance, and exporters who can protect their reputation in every shipment. This is exactly why Vietnam has become one of the world’s strongest plywood export hubs, and why the most serious buyers consistently choose HCPLY.

HCPLY is not just another name on the list of Plywood Exporters in Vietnam — we are a factory-direct, high-capacity manufacturer trusted by buyers across Europe, the Middle East, LATAM, North America, and Asia. Every container we ship reflects our commitment to quality, engineering, transparency, and long-term partnership. From eucalyptus and acacia veneer to phenolic glue, AICA/Dynea film, calibrated sanding, strict QC, and full international documentation, HCPLY delivers everything modern buyers expect from a world-class exporter.

If your business depends on stable supply, consistent quality, competitive pricing, and a reliable Vietnamese manufacturing partner — HCPLY stands ready as your strongest long-term plywood supplier.

Let’s build your market advantage together.