The global plywood market has entered a turning point.

For years, European buyers depended on China and Russia for birch and light interior panels. Today, sanctions, anti-dumping duties, unstable supply, and rising logistics costs have forced buyers to rethink their sourcing strategy — not by choice, but by necessity.

This is exactly where poplar plywood from Vietnam emerges as the smartest alternative.

Produced at factory scale, optimized for weight, cost, and EU compliance, poplar plywood from Vietnam is no longer a secondary option — it is a strategic material shift. As a leading manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood delivers poplar plywood solutions designed specifically for European furniture, interior, and panel applications where stability, consistency, and long-term supply matter most.

Table of contents

Top 10 Film Faced Plywood Manufacturers in Vietnam 2025

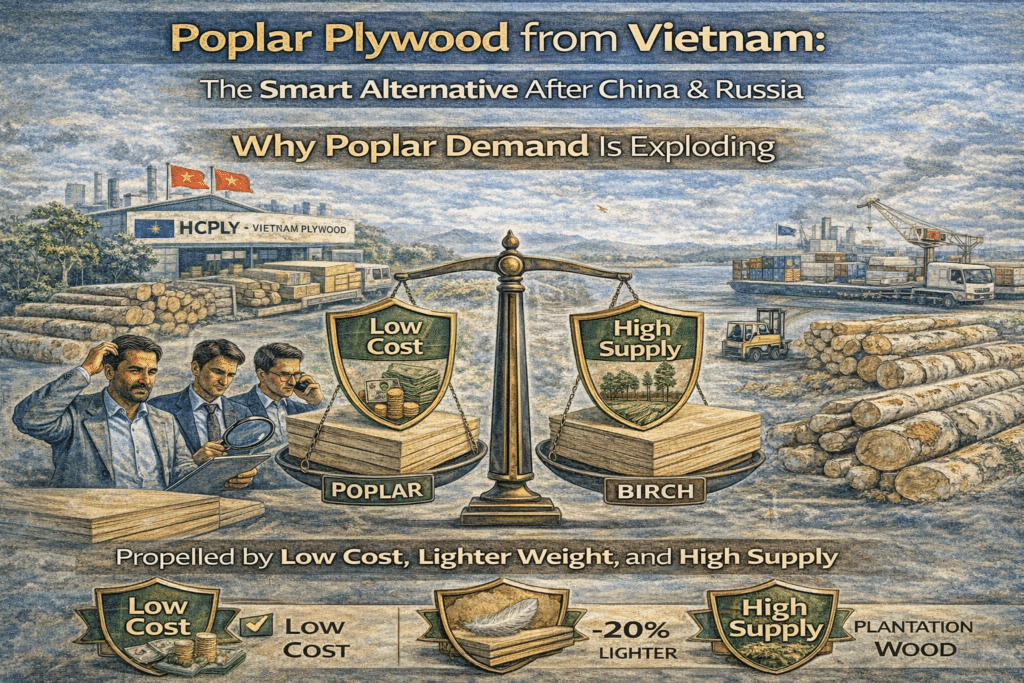

🔥 1️⃣ Why Poplar Demand Is Exploding

The surge in demand for poplar plywood from Vietnam is not a trend — it is a structural shift in global sourcing. European buyers are moving fast because the old supply model has collapsed.

For more than a decade, China and Russia dominated light interior plywood. Today, that dominance is broken. Sanctions, anti-dumping duties, geopolitical uncertainty, and unstable logistics have turned traditional sourcing into a liability. Buyers are no longer optimizing for cheap price — they are optimizing for supply certainty, compliance, and controllable risk.

This is where poplar plywood from Vietnam becomes the smart alternative.

Vietnam offers plantation-grown poplar and white core materials, factory-scale production, and export-ready systems aligned with EU requirements. Unlike temporary stop-gap suppliers, Vietnam has invested deeply in long-term manufacturing capacity, consistency, and compliance infrastructure.

As a leading manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood produces poplar plywood at industrial scale, with stable quality, optimized weight, and competitive factory pricing — exactly what European furniture brands, importers, and OEM factories now require.

Why demand is accelerating:

- ✔️ Collapse of Russia birch supply

- ✔️ Rising anti-dumping and trade risks from China

- ✔️ Strong EU acceptance of poplar plywood from Vietnam

- ✔️ Lightweight panels optimized for container efficiency

- ✔️ Factory-controlled production with long-term scalability

The market has already moved. Poplar plywood from Vietnam is no longer an alternative — it is becoming the new baseline.

2️⃣ Poplar vs Birch: Reality Check

For years, birch plywood has been treated as the default benchmark for European furniture and interior applications. Its reputation was built on strength, clean appearance, and predictable performance — but that benchmark was created under a supply reality that no longer exists.

Today, buyers are forced to face a hard truth: birch is no longer a stable material category.

Sanctions on Russia, shrinking legal supply, and heavy dependence on a limited number of origins have turned birch plywood into a high-risk material. Availability fluctuates, prices spike without warning, and long-term contracts are increasingly difficult to secure. In many cases, buyers are paying more — not for better performance, but for uncertainty.

This is where Poplar Plywood from Vietnam changes the conversation.

From a technical standpoint, poplar plywood is not designed to replace birch in every application — and that is exactly why it works. In furniture carcasses, interior panels, laminated boards, and painted surfaces, poplar plywood delivers the required performance without unnecessary excess weight or cost.

Birch is harder and heavier. Poplar is lighter, easier to machine, and more efficient in downstream processing. When paired with controlled white core or styrax core structures, Poplar Plywood from Vietnam achieves flatness, bonding strength, and dimensional stability that meet real-world EU requirements — not theoretical benchmarks.

The reality check is simple:

- Birch plywood is becoming a scarce premium material

- Many applications do not require full birch performance

- Buyers are now optimizing for supply security, consistency, and total cost

- Poplar Plywood from Vietnam fits this new decision framework

This shift is not about downgrading quality.

It is about matching material performance to actual application needs — and avoiding unnecessary risk in a volatile global plywood market.

The market is no longer asking “Is poplar as strong as birch?”

It is asking “Why are we still paying birch prices for applications that do not need birch?”

3️⃣ Styrax / White Core Advantage

One of the key reasons poplar plywood from Vietnam has gained strong acceptance in the EU market lies beneath the surface — in the styrax (white core) structure.

Unlike traditional mixed hardwood cores, styrax / white core plywood is engineered specifically for interior furniture and laminated applications where light weight, clean bonding, and dimensional stability matter more than brute strength.

Styrax wood is naturally light, uniform in fiber structure, and low in internal stress. When used as the core for poplar plywood from Vietnam, it delivers three critical advantages European buyers actively look for today.

First: weight control.

Styrax core significantly reduces panel weight compared to eucalyptus or full hardwood cores. This directly improves container loading efficiency, handling speed in factories, and overall logistics cost — a major advantage when shipping poplar plywood from Vietnam to Europe.

Second: superior bonding & lamination performance.

White core panels provide a clean, neutral surface for gluing, veneering, laminating, or painting. For furniture carcasses, laminated boards, and painted interiors, styrax-based poplar plywood from Vietnam ensures consistent glue absorption, reduced telegraphing, and stable surface finish.

Third: structural consistency.

Unlike mixed cores that vary batch to batch, controlled styrax core production allows factories to maintain uniform density, thickness tolerance, and internal balance. This consistency is critical for buyers running CNC cutting, edge banding, or automated furniture lines.

In practical terms, styrax core does not aim to compete with birch in strength — it outperforms birch in application efficiency. Most interior furniture components simply do not require heavy hardwood cores, but they do require predictability, flatness, and clean processing.

That is why more European manufacturers are shifting toward poplar plywood from Vietnam with white core, especially for:

- Furniture carcasses

- Laminated panels

- Painted interior components

- Lightweight modular systems

When properly manufactured, styrax-core poplar plywood from Vietnam is not a compromise — it is a smarter material choice aligned with modern EU furniture production.

⚖️ 4️⃣ Weight & Handling Benefits

Weight has become one of the most underestimated cost drivers in modern plywood sourcing — and this is where poplar plywood from Vietnam delivers a decisive advantage.

Compared to birch and heavy hardwood panels, poplar plywood from Vietnam is engineered to be significantly lighter while maintaining the structural stability required for furniture and interior use. This weight optimization is not accidental; it is the result of controlled core selection, calibrated pressing cycles, and factory-level production planning.

For European buyers, lighter panels translate directly into operational benefits across the entire supply chain.

In logistics and container loading, poplar plywood from Vietnam allows higher usable CBM per container without hitting weight limits. This improves freight efficiency and lowers landed cost per cubic meter — a critical factor in long-distance shipping from Asia to Europe.

In factory handling, lighter panels reduce labor strain, speed up processing, and minimize damage during internal movement. CNC cutting, edge banding, drilling, and assembly become faster and more consistent when panel weight is predictable and manageable.

In finished furniture, reduced weight improves ergonomics, simplifies installation, and lowers transportation costs for downstream distribution — especially important for flat-pack and modular furniture systems.

As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood designs poplar plywood specifications with weight control as a core performance parameter, not an afterthought. Panel density, thickness tolerance, and internal balance are optimized to meet real EU production conditions.

Why weight matters more than ever:

- ✔️ Higher container efficiency

- ✔️ Lower inland handling cost

- ✔️ Faster furniture processing

- ✔️ Reduced breakage and rejection

- ✔️ Better suitability for modular furniture

In today’s market, choosing poplar plywood from Vietnam is not only a material decision — it is a logistics and efficiency strategy built into the product itself.

🪑 5️⃣ Furniture Application Fit

The real strength of poplar plywood from Vietnam is revealed not in laboratory tests, but on the furniture production floor — where efficiency, consistency, and surface quality determine profit.

Across Europe, furniture manufacturers are redesigning products to reduce weight, simplify assembly, and stabilize sourcing. In this context, poplar plywood from Vietnam fits naturally into modern furniture architecture.

For carcass construction, poplar plywood provides sufficient structural rigidity while remaining easy to cut, drill, and edge-band. CNC machines operate faster, tooling wear is reduced, and dimensional tolerance remains stable across production batches — all critical for volume furniture lines.

For laminated and painted furniture, poplar plywood from Vietnam offers a clean, uniform base. Combined with white core or styrax core structures, panels deliver excellent bonding behavior for melamine, HPL, veneer, and paint finishes. This minimizes surface defects, reduces rejection rates, and improves final product appearance.

For flat-pack and modular furniture, weight becomes a decisive factor. Lighter panels reduce packaging stress, lower transport cost, and improve end-user handling. Many EU brands now actively specify poplar plywood from Vietnam for wardrobes, cabinets, shelving systems, and interior partitions.

Typical furniture applications include:

- ✔️ Furniture carcasses and frames

- ✔️ Wardrobes, cabinets, and shelving

- ✔️ Laminated panels and veneered boards

- ✔️ Painted interior furniture components

- ✔️ Modular and flat-pack furniture systems

As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood designs poplar plywood specifications specifically for furniture use — controlling core quality, glue systems, and pressing parameters to match real production requirements.

In practice, poplar plywood from Vietnam is not a compromise material.

It is a purpose-built solution for furniture manufacturers who prioritize efficiency, scalability, and long-term supply stability.

💰 6️⃣ Cost Optimization Without Quality Sacrifice

Cost optimization is no longer about choosing the cheapest plywood — it is about reducing total cost without increasing risk. This is exactly where poplar plywood from Vietnam delivers a structural advantage for European buyers.

Birch plywood prices have become volatile due to sanctions, limited legal supply, and high logistics costs. Buyers are paying premiums not for better performance, but for unstable availability. In contrast, poplar plywood from Vietnam is produced from plantation-grown raw materials with predictable input costs and scalable factory output.

From a factory perspective, poplar allows tighter cost control at every stage:

- Raw material sourcing is stable and plantation-based

- Core structures are optimized for yield and consistency

- Pressing cycles consume less energy due to lighter density

- Waste and rejection rates are significantly lower

These efficiencies translate directly into competitive factory pricing without compromising bonding strength, flatness, or surface quality.

Logistics further amplify the advantage. Because poplar plywood from Vietnam is lighter, buyers gain higher usable CBM per container and lower freight cost per panel. Over annual volumes, this difference becomes substantial — especially for furniture manufacturers running repeat shipments.

Just as important, cost predictability enables long-term contracts. European importers and OEMs increasingly value suppliers who can hold pricing bands across quarters, not just offer a low spot price. As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood structures poplar plywood programs around stable cost planning, not short-term speculation.

Why poplar optimizes cost without sacrificing quality:

- ✔️ Lower and more stable raw material cost

- ✔️ Reduced freight and handling expense

- ✔️ Consistent factory yield and quality

- ✔️ Fewer production disruptions

- ✔️ Reliable long-term pricing

In today’s market, poplar plywood from Vietnam is not a cheaper alternative — it is a smarter cost structure, engineered at factory level for buyers who think beyond FOB price.

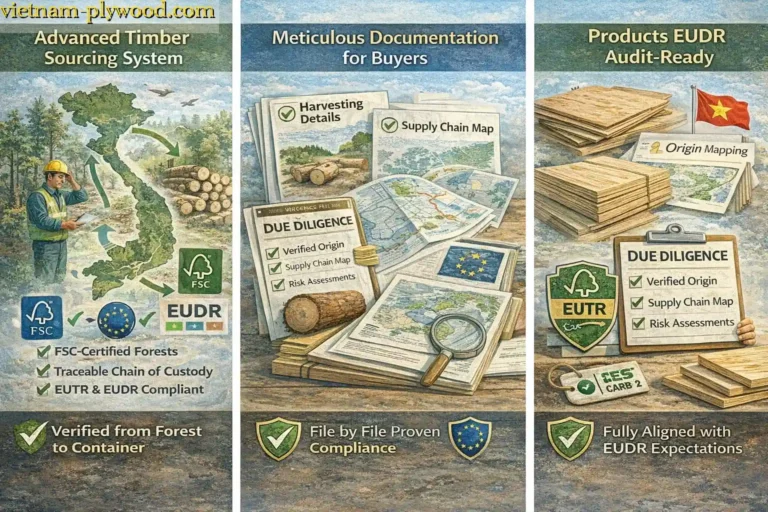

🌍 7️⃣ EU Market Acceptance Is No Longer a Question

A few years ago, European buyers asked whether poplar plywood from Vietnam would be accepted by their customers, inspectors, and downstream partners.

Today, that question has already been answered by the market itself.

Across Germany, France, the Netherlands, Italy, and Scandinavia, poplar plywood from Vietnam is now widely specified for furniture carcasses, interior panels, laminated boards, and painted applications. What began as a contingency solution has evolved into an approved, standardized material choice.

This acceptance did not happen by marketing — it happened through real performance at factory scale.

European importers and furniture brands have validated poplar plywood from Vietnam through:

- Long production runs

- Repeated container shipments

- Internal quality audits

- Customer feedback from finished products

The result is clear: when manufactured correctly, poplar plywood from Vietnam meets EU expectations for flatness, bonding, appearance, and consistency.

Regulatory confidence has also played a critical role. Plantation-based sourcing, stable species declaration, and transparent documentation have made poplar plywood from Vietnam far easier to position under EUTR and EUDR frameworks compared to high-risk hardwood origins. For compliance-focused buyers, this alone is a decisive factor.

Just as important is design acceptance. Many European brands have quietly updated internal material specifications — replacing birch with poplar plywood from Vietnam for non-structural components where weight, cost, and stability matter more than excess hardness.

Why EU buyers now accept poplar plywood from Vietnam as standard:

- ✔️ Proven performance in real furniture production

- ✔️ Stable appearance and surface quality

- ✔️ Easier compliance positioning under EU regulations

- ✔️ Lower logistics and handling risk

- ✔️ Consistent supply across multiple years

As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood has supported this shift by delivering poplar plywood programs aligned with EU technical standards, documentation requirements, and long-term supply planning.

In today’s European market, poplar plywood from Vietnam is no longer “under evaluation.”

It is already integrated into purchasing decisions, contracts, and product lines.

🏭 8️⃣ Manufacturing Requirements Behind Real Poplar Quality

The rapid success of poplar plywood from Vietnam in the EU market has revealed an important truth: poplar is only a smart alternative when it is manufactured correctly. Without proper factory systems, poplar plywood can quickly become inconsistent, unstable, and rejected by serious buyers.

High-quality poplar plywood from Vietnam requires far more than basic pressing. It demands industrial-scale manufacturing discipline, precise process control, and long-term investment — areas where only real factories with large capacity can deliver consistent results.

From a production standpoint, several requirements are non-negotiable:

- Controlled core selection

Poplar and styrax cores must be sorted by density and moisture content. Mixed or uncontrolled cores lead to warping, thickness variation, and bonding failure. - Advanced glue systems

Interior and furniture-grade poplar plywood from Vietnam relies on calibrated E0/E1 glue formulations. Glue spread rate, viscosity, and curing temperature must be precisely managed to ensure clean bonding without over-penetration. - Multi-stage pressing control

Pressing cycles for poplar are different from hardwood plywood. Temperature, pressure, and dwell time must be optimized to avoid internal stress while maintaining flatness and strength. - Moisture equilibrium management

Proper conditioning before and after pressing is critical. Without it, poplar panels may perform well initially but fail after shipment or installation in Europe. - Inline quality monitoring

Thickness tolerance, panel balance, and surface integrity must be checked continuously — not randomly. This is essential for buyers running CNC and automated furniture lines.

As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood operates poplar plywood production as a dedicated system — not as a secondary product. Factory layouts, machinery, and labor training are specifically designed around poplar panel characteristics and EU application requirements.

This is why serious European buyers increasingly focus not just on material type, but on manufacturing capability behind the material. Poplar plywood from Vietnam succeeds because it is supported by real factories with scalable capacity, disciplined processes, and export-focused quality control.

In today’s market, poplar plywood quality is not determined by the species alone —

it is determined by how the factory is built to produce it.

🏭 9️⃣ HCPLY Poplar Plywood Solutions Built for Europe

The success of poplar plywood from Vietnam in the European market does not come from theory — it comes from how the product is engineered, produced, and supplied at factory scale. This is exactly where HCPLY – Vietnam Plywood stands apart.

As a leading manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood does not treat poplar plywood as a side product. It is a core production line, designed specifically for European furniture, interior, and panel applications where consistency, compliance, and long-term supply matter more than short-term price.

HCPLY poplar plywood solutions are built on four factory-level pillars.

First: controlled raw material sourcing

HCPLY uses plantation-grown poplar and white core materials with stable species declaration. Core veneers are dried, sorted, and balanced to ensure moisture equilibrium and panel stability during long-distance export to Europe.

Second: application-driven core structures

Depending on end use, HCPLY produces poplar plywood from Vietnam with styrax (white core), balanced poplar core, or hybrid structures — optimized for furniture carcasses, laminated boards, and painted interiors. Core design is matched to application, not standardized blindly.

Third: export-grade production systems

Multi-opening presses, calibrated glue lines (E0 / E1 / CARB-ready), and industrial sanding systems allow HCPLY to maintain tight thickness tolerance and strong internal bonding across high-volume production. Quality is controlled batch by batch, not shipment by shipment.

Fourth: scalable capacity & long-term programs

European buyers need continuity. HCPLY operates poplar plywood production at large capacity, enabling stable monthly supply, repeat container programs, and long-term contracts without quality drift. This scalability is critical as buyers replace birch and China-origin panels across entire product lines.

What European buyers gain with HCPLY poplar plywood solutions:

- ✔️ Factory-direct poplar plywood from Vietnam

- ✔️ Stable quality across repeat shipments

- ✔️ Optimized weight and logistics efficiency

- ✔️ EU-ready compliance and documentation

- ✔️ Competitive factory pricing with long-term cost control

For European importers, furniture brands, and OEM manufacturers, HCPLY – Vietnam Plywood is not just a supplier — it is a production partner supporting material transition at scale.

In a market where poplar plywood from Vietnam has become a strategic alternative, HCPLY delivers not promises, but factory-built solutions designed for Europe’s next sourcing cycle.

🚀 🔟 Transition CTA – Move Forward with Poplar Plywood from Vietnam

The global plywood market has already crossed a point of no return. After China and Russia, European buyers are no longer searching for a temporary replacement — they are building a new, long-term sourcing structure.

This is where poplar plywood from Vietnam becomes a strategic decision, not just a material choice.

For furniture brands, importers, and OEM factories, the next step is clear:

- Replace unstable origins with plantation-based, factory-controlled supply

- Shift from short-term pricing to long-term cost predictability

- Work directly with a large-scale Vietnam plywood manufacturer, supplier, and exporter capable of supporting growth over years — not just containers

As a leading manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood supports this transition with:

- Factory-direct poplar plywood programs

- Stable monthly capacity and repeat shipments

- EU-ready specifications and documentation

- Competitive pricing backed by real production scale

If your sourcing strategy is evolving beyond China and Russia, poplar plywood from Vietnam is no longer the question.

The question is how fast you secure the right factory partner.

👉 Explore HCPLY – Vietnam Plywood poplar solutions

👉 Request samples and technical specifications

👉 Start building a stable, scalable plywood supply for Europe

🔗 Explore Related Vietnam Plywood Solutions from a Leading Manufacturer

As European buyers restructure sourcing beyond China and Russia, many are expanding their portfolios with factory-direct plywood products from Vietnam to balance cost, performance, and compliance.

Alongside poplar plywood from Vietnam, HCPLY – Vietnam Plywood manufactures and exports a full range of panels trusted by EU importers, furniture brands, and construction buyers:

For decorative and interior applications, buyers often combine poplar with birch plywood from Vietnam, okoume plywood from Vietnam, bintangor plywood from Vietnam, or gurjan plywood from Vietnam, depending on surface appearance and finishing requirements.

For lightweight structures and cost-controlled interiors, many programs integrate EV plywood from Vietnam, supported by stable raw material sourcing through core veneer from Vietnam produced under factory-controlled conditions.

In construction, formwork, and industrial use, buyers frequently specify film faced plywood from Vietnam and anti-slip plywood from Vietnam, benefiting from consistent pressing systems and scalable export capacity.

For packaging, crates, and non-structural logistics solutions, packing plywood from Vietnam remains a reliable option, often paired with pine plywood from Vietnam for optimized weight and cost.

Where higher strength or density is required, European buyers may selectively use eucalyptus plywood from Vietnam or matt plywood from Vietnam, depending on load and surface performance.

All these product lines — including poplar plywood from Vietnam — are manufactured, supplied, and exported directly by HCPLY – Vietnam Plywood, a leading Vietnam plywood manufacturer with large capacity, stable quality control, EU-ready compliance, and competitive factory pricing.

This integrated product range allows European buyers to consolidate sourcing with one reliable factory partner, while adapting materials to each application with confidence.