Table of contents

How to Choose the Right Plywood Core | plywood core selection from a Vietnam plywood manufacturer | HCPLY – Vietnam Plywood

European buyers often evaluate plywood by what they can see first — face veneer, thickness, or FOB price. But after years of exporting at factory scale, HCPLY – Vietnam Plywood has learned one critical truth: the plywood core quietly decides everything that really matters — weight, container loading efficiency, real landed cost, performance stability, and long-term buyer satisfaction.

From our position as a Vietnam plywood manufacturer, direct supplier, and exporter with large production capacity, we see daily how two buyers ordering the same face veneer can end up with completely different costs, margins, and complaints — simply because they chose different core materials. This is the hidden gap between trading descriptions and factory reality.

This article is not written from a sales desk or a reseller’s catalog. It is written from the factory floor of HCPLY – Vietnam Plywood, where plywood core selection is calculated in kilograms per cubic meter, container payload limits, glue bonding behavior, sanding tolerance, and EU market expectations — not marketing slogans.

If you source plywood from Vietnam for Europe, understanding plywood core selection is no longer optional. It is the difference between shipping profitably or paying invisible costs after the container arrives. And as a leading Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY shares this practical guide so buyers can choose cores based on facts, math, and manufacturing truth — not habit.

🔹 1️⃣ Why Plywood Core Choice Matters More Than Buyers Think

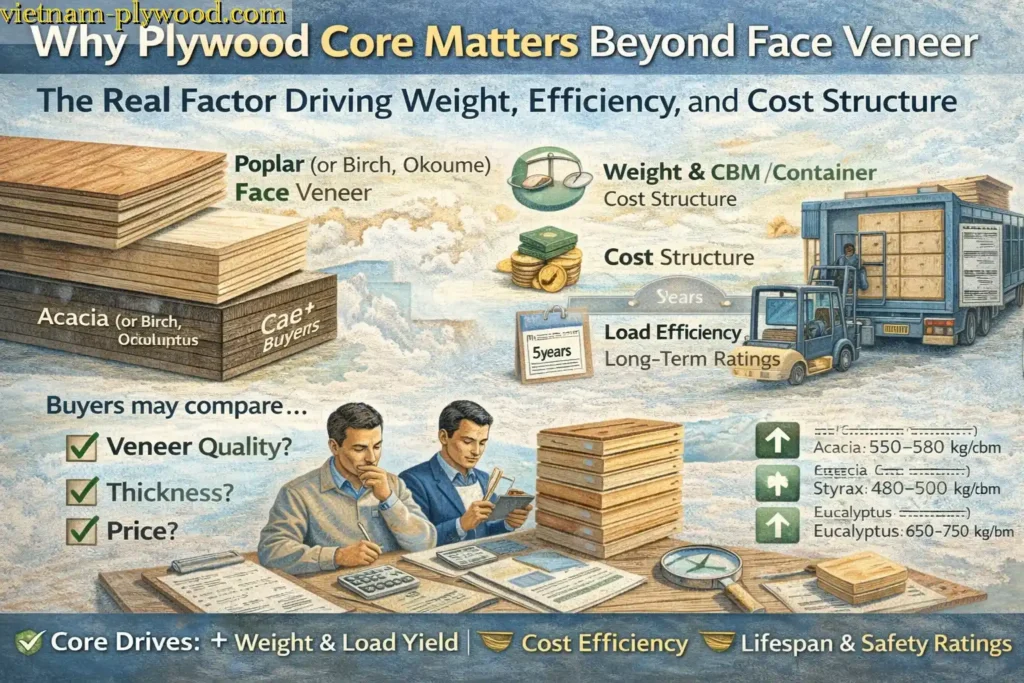

Most plywood buyers still compare products by face veneer appearance, thickness, or FOB price. From the trading side, this seems logical. But from the factory perspective of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, this approach misses the single most important factor: the plywood core.

At production scale, the core is not just a technical detail hidden inside the board. It is the real cost driver, the real performance driver, and the real risk driver behind every plywood shipment exported from Vietnam to Europe.

🔍 Core = The Hidden Cost & Performance Engine

From a factory standpoint, plywood core selection directly determines:

- ⚙️ Panel weight & density consistency

- 🚢 Container loading capacity (CBM per 40HQ)

- 💰 Real landed cost, not just FOB price

- 🧱 Bonding strength, sanding tolerance, and structural stability

- 📉 Risk of claims, warping, delamination, and surface issues

Two plywood panels with identical face veneer and thickness can perform very differently in real use — simply because the core inside is different. This is a daily reality at HCPLY – Vietnam Plywood, where thousands of cubic meters are produced, loaded, and exported every month.

🇪🇺 Why European Buyers Now Ask About Core Density

European importers, distributors, and OEM buyers are becoming more technical. Instead of asking only:

- “Is it birch face or poplar face?”

- “What is the FOB price per CBM?”

They increasingly ask:

- 📏 What is the core density (kg/cbm)?

- 🚛 How many CBM can be loaded per 40HQ?

- 📦 What is the weight per bundle or pallet?

- 📜 Is the core plantation-sourced and traceable?

This shift happens because European buyers understand that freight, compliance, and consistency now matter more than ever. As a leading Vietnam plywood manufacturer and exporter, HCPLY sees this change clearly in buyer inquiries year after year.

🏭 Factory Reality vs Trading Descriptions

From a trading description, many plywood products look the same:

- “Hardwood core”

- “Mixed core”

- “White core”

- “Strong core plywood”

From the factory floor, these terms are far too vague.

At HCPLY – Vietnam Plywood, plywood core selection is defined by:

- ✅ Exact wood species

- ✅ Measured density ranges

- ✅ Glue absorption behavior

- ✅ Pressing cycles and pressure tolerance

- ✅ Container payload math, not estimates

This is where the gap appears. Buyers working only with traders often discover core-related problems after the container arrives — when freight cost, weight limits, or end-use performance no longer match expectations.

As a Vietnam plywood manufacturer, supplier, and exporter with large production capacity, HCPLY emphasizes one principle across all export markets:

👉 You don’t buy plywood by its face — you buy it by its core.

Understanding this principle is the foundation for every block that follows in this practical plywood core selection guide.

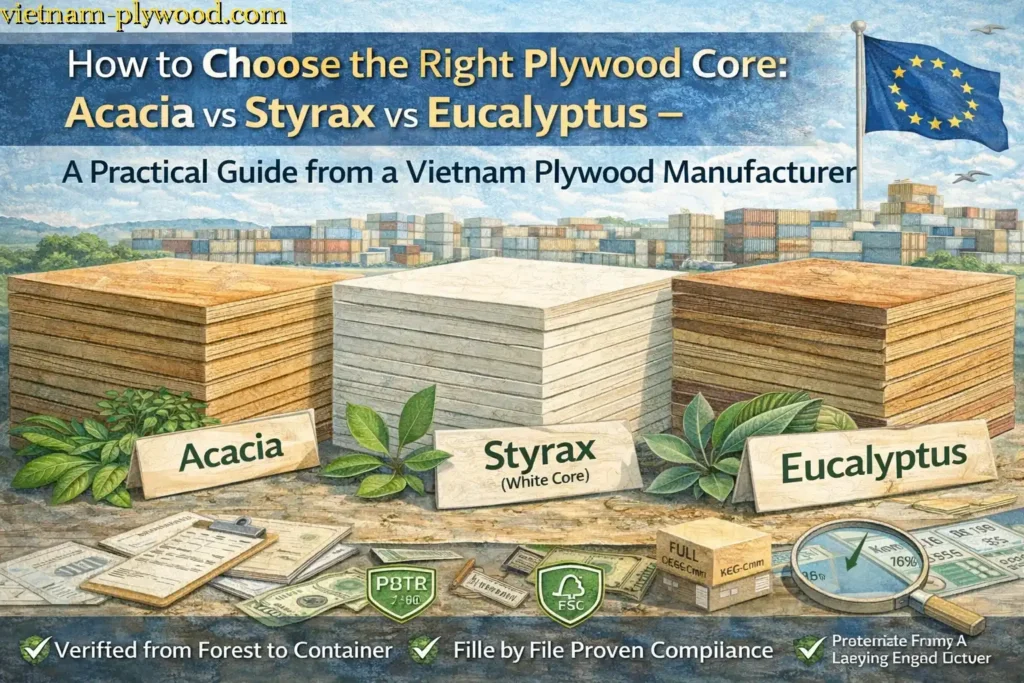

🔹 2️⃣ Overview of Common Plywood Core Options from Vietnam

Vietnam is one of the few countries capable of supplying multiple plywood core options at industrial scale, with stable plantation sources, experienced labor, and export-oriented factories. From the manufacturing perspective of HCPLY – Vietnam Plywood, a leading Vietnam plywood manufacturer, supplier, and exporter, the market is clearly dominated by three core types — each serving very different buyer needs.

🌳 Acacia Core

- Widely planted plantation wood in Vietnam

- Balanced density, strong internal bonding

- Cost-efficient and stable for mass export

- The volume backbone of Vietnam plywood exports

🌲 Styrax Core (White Core / Alstonia scholaris)

- Plantation-sourced light hardwood

- Naturally white color, uniform texture

- Ideal for high-end surface finishing

- Strong demand from European furniture and interior buyers

🌴 Eucalyptus Core

- Fast-growing hardwood plantation species

- Highest density and mechanical strength

- Heavier panels, lower CBM per container

- Used selectively for structural or load-critical applications

🇻🇳 Why Vietnam Is a Key Origin for All Three Cores

From the factory side, Vietnam offers a rare combination:

- 🌱 Large-scale plantation resources for acacia, styrax, and eucalyptus

- 🏭 Integrated plywood manufacturing capacity, not just trading

- 📦 Export-ready production lines optimized for EU standards

- 📜 Traceability and compliance frameworks aligned with EUTR / EUDR

At HCPLY – Vietnam Plywood, these three core types are not theoretical options — they are daily production decisions, calculated by density, loading efficiency, glue behavior, and buyer market requirements. Understanding their differences is the first step in making the right plywood core selection from a true Vietnam plywood manufacturer and exporter, not from generic trading descriptions.

In the next blocks, each core type will be analyzed in depth — with real density data, factory performance insight, and export math — to help buyers choose based on facts, not assumptions.

🔹 3️⃣ Acacia Core Explained: Cost-Efficient & High Bonding Strength

Among all plywood core options exported from Vietnam, acacia core remains the most widely used and commercially balanced solution. From the factory perspective of HCPLY – Vietnam Plywood, a leading Vietnam plywood manufacturer, supplier, and exporter, acacia is not chosen by accident — it is chosen by math, performance data, and export reality.

🌳 Acacia Core Density & Physical Profile

- ⚖️ Density range: 550–580 kg/cbm

- 📐 Medium-weight hardwood core

- 🔩 Stable structure with consistent veneer layers

- ⚙️ Excellent glue absorption and bonding behavior

This density range places acacia in the optimal middle ground — lighter than eucalyptus, yet stronger and more stable than many mixed or low-density cores commonly offered by traders.

🧱 High Bonding Performance at Factory Scale

At HCPLY – Vietnam Plywood, acacia core is favored in production because:

- ✅ Veneer fibers accept glue evenly

- ✅ Strong inter-layer bonding under hot press

- ✅ Low risk of delamination when pressed correctly

- ✅ Good sanding tolerance without core exposure

From a manufacturing standpoint, this translates into stable quality across large volumes, which is essential for a Vietnam plywood manufacturer exporting thousands of CBM to Europe every year.

💰 Cost-Efficient Without Sacrificing Stability

Acacia is widely planted in Vietnam as a plantation species, giving it:

- 🌱 Reliable raw material supply

- 📉 Competitive and predictable pricing

- 📦 Efficient yield in veneer production

This makes acacia core the most cost-efficient option for buyers who need:

- Consistent quality

- Scalable volumes

- Competitive FOB pricing

- Controlled production risk

🇪🇺 Why Price-Sensitive EU Buyers Choose Acacia

For many European importers and distributors, acacia core offers the best balance between price, performance, and freight efficiency:

- 🚢 Better CBM loading per container than eucalyptus

- 💶 Lower material cost than premium cores

- 📊 Predictable landed cost for repeat orders

- 🧾 Easier planning for long-term supply contracts

This is why, from the export data of HCPLY – Vietnam Plywood, acacia remains the volume driver for EU-bound plywood — especially for commercial plywood, film faced plywood, and cost-controlled interior applications.

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY positions acacia core not as a “cheap option,” but as a factory-proven, export-optimized solution when buyers want reliable performance at a competitive cost.

In the next block, we will move to a lighter and more surface-focused option increasingly favored by European furniture buyers: Styrax (White Core).

🔹 4️⃣ Styrax (White Core) Explained: Lightweight & Surface-Friendly

As European buyers move toward higher surface standards and lighter finished products, styrax core (white core / Alstonia scholaris) has become one of the fastest-growing plywood core choices. From the factory perspective of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, styrax is selected not for marketing appeal, but for weight efficiency, surface compatibility, and EU-end-use logic.

🌲 Styrax Core Density & Physical Characteristics

- ⚖️ Density range: 480–500 kg/cbm

- 📉 One of the lightest hardwood plywood cores available

- 🎨 Naturally full white core, uniform in color

- 📐 Smooth veneer layers with low density variation

This low-density profile allows styrax core plywood to significantly reduce panel weight without compromising basic structural integrity for furniture and interior applications.

🎯 Why White Core Matters for Surface Quality

From a manufacturing standpoint at HCPLY – Vietnam Plywood, white core is not an aesthetic concept — it is a technical advantage:

- 🪵 Reduced risk of dark core bleeding through thin face veneers

- 🧽 Cleaner sanding results with minimal color shadowing

- 🎯 More forgiving during lamination and finishing

- 🧱 Better consistency under thin decorative faces

This is why styrax core is strongly preferred when producing plywood with poplar, birch, okoume, or other light-colored face veneers.

🇪🇺 Why European Buyers Prefer Styrax Core

European furniture manufacturers and distributors increasingly specify styrax core because it delivers:

- 🪑 Lighter finished furniture products

- 🚢 Improved container weight optimization

- 🎨 Higher surface appearance consistency

- 📦 Lower risk of visual defects after cutting and finishing

From export data at HCPLY – Vietnam Plywood, styrax core plywood is commonly ordered for:

- Furniture-grade plywood

- Interior decorative panels

- OEM projects where surface perfection is critical

💰 Cost Positioning: Between Acacia and Eucalyptus

Styrax core typically sits between acacia and eucalyptus in cost:

- 💵 Higher than acacia due to lower yield and higher selection standards

- 💵 Lower than eucalyptus due to reduced density and pressing demand

- 📊 Balanced option for buyers seeking performance over raw strength

For buyers who value appearance, weight reduction, and premium surface quality, styrax core delivers a strong return despite a slightly higher FOB price.

🏭 Factory Insight from HCPLY – Vietnam Plywood

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY positions styrax core as:

- ✅ A surface-driven solution, not a structural one

- ✅ Ideal for EU furniture and interior markets

- ✅ Best paired with light face veneers

- ❌ Not recommended where maximum load-bearing strength is required

Styrax core is a strategic choice — not for every application, but for the right application. In the next block, we will examine the opposite end of the spectrum: Eucalyptus core, where strength and density dominate every calculation.

🔹 5️⃣ Eucalyptus Core Explained: Maximum Strength & Load Capacity

At the opposite end of the plywood core spectrum stands eucalyptus core — the densest, strongest, and most demanding option to manufacture. From the factory perspective of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, eucalyptus core is never positioned as a default choice, but as a purpose-driven material where strength truly matters.

🌴 Eucalyptus Core Density & Mechanical Profile

- ⚖️ Density range: 650–750 kg/cbm

- 🧱 High compression strength

- 📐 Superior bending and load-bearing performance

- 🏗️ Extremely rigid internal structure

This high-density profile makes eucalyptus the strongest plywood core commonly exported from Vietnam, but it also introduces weight, cost, and freight trade-offs that buyers must clearly understand.

🏋️ Maximum Strength Comes with Maximum Weight

From a production and export standpoint at HCPLY – Vietnam Plywood, eucalyptus core creates a very clear equation:

- ✅ Higher mechanical strength

- ❌ Heavier panels

- ❌ Lower CBM loading per container

- ❌ Higher freight cost per CBM

Compared to acacia or styrax, eucalyptus core plywood reaches container weight limits much faster, directly reducing the total volume that can be loaded into a 40HQ container.

💰 Why Eucalyptus Core Carries a Price Premium

The higher cost of eucalyptus core is driven by factory realities, not marketing:

- 🌱 Plantation cycles and log cost are higher

- 🔪 Harder wood increases veneer processing wear

- 🔥 Higher pressing pressure and energy consumption

- 📉 Lower CBM yield per container due to weight limits

As a Vietnam plywood manufacturer exporting to Europe, HCPLY – Vietnam Plywood must factor all of these into FOB pricing — making eucalyptus core the most expensive option on a per-CBM basis.

🧠 When Eucalyptus Is the Right Choice

Eucalyptus core is justified when buyers require:

- 🏗️ High structural integrity

- 🧱 Strong load-bearing performance

- 🛠️ Resistance to deformation under pressure

- 📐 Dimensional stability in demanding environments

Typical applications include:

- Structural plywood

- Heavy-duty industrial panels

- Certain film faced plywood requirements

- Applications where strength outweighs freight efficiency

⚠️ When Eucalyptus Is the Wrong Choice

From export experience at HCPLY – Vietnam Plywood, eucalyptus core is not recommended when:

- 🚢 Freight efficiency is critical

- 🪑 Furniture weight reduction is required

- 🎨 Surface appearance is the priority

- 💶 Buyers aim to optimize landed cost rather than raw strength

Many European buyers over-specify eucalyptus core based on assumptions — only to discover later that they paid more for strength they never needed.

🏭 Factory Insight from HCPLY – Vietnam Plywood

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY positions eucalyptus core as:

- ✅ A strength-driven solution

- ✅ Best for structural and industrial uses

- ❌ Inefficient for furniture and decorative panels

- ❌ Unsuitable for buyers optimizing CBM and freight cost

Eucalyptus core delivers unquestionable strength — but strength alone does not guarantee a better plywood solution. In the next block, we will connect core density directly to real container loading math, where the true cost impact becomes impossible to ignore.

🔹 6️⃣ Core Density vs Container Loading: Real 40HQ Math

From the export floor of HCPLY – Vietnam Plywood, one reality is always clearer than any brochure: containers are limited by weight long before they are limited by space. This is why plywood core density is not a theoretical number — it is the key variable that decides how much product actually ships, how much freight is paid, and how much margin remains after landing in Europe.

⚖️ Why Core Density Directly Controls Container Capacity

A 40HQ container has:

- 📦 Fixed internal volume

- 🚢 Strict maximum payload weight

As a Vietnam plywood manufacturer and exporter operating at large volume, HCPLY calculates container loading based on total weight tolerance, not optimistic CBM assumptions. The denser the core, the faster a container reaches its legal weight limit — even when physical space remains unused.

In practice, this means:

- ❌ You cannot “fill the container” just because space is available

- ❌ You cannot ignore density and rely on nominal CBM

- ✅ You must load based on kg first, CBM second

🏭 Factory-Calculated Loading Limits (Not Estimates)

At HCPLY – Vietnam Plywood, container planning is calculated using:

- 📐 Average panel density (kg/cbm)

- 📦 Bundle and pallet weight

- ⚖️ Container payload limits

- 🧮 Safety margins for port and shipping line regulations

This factory-level math determines real exportable volume, not the theoretical volume shown in trading offers.

📊 Cost-per-CBM vs Freight Efficiency

Many buyers focus only on:

- 💵 FOB price per CBM

But from an exporter’s perspective, the more accurate metric is:

- 💰 Freight cost per CBM actually loaded

A higher-density core may appear acceptable at FOB level, but:

- 🚢 Loads fewer CBM per container

- 📈 Increases freight cost per CBM

- 📉 Reduces landed cost efficiency

This is why, from HCPLY – Vietnam Plywood’s export data, two plywood orders with similar FOB pricing can result in very different landed costs, purely due to core density differences.

⚠️ The Hidden Mistake Many Buyers Make

Buyers often assume:

- “All plywood loads the same”

- “Core type only affects strength”

- “FOB price is the main comparison point”

From the manufacturing and exporting reality, all three assumptions are incorrect.

As a leading Vietnam plywood manufacturer, supplier, and exporter, HCPLY emphasizes one rule in every technical discussion with EU buyers:

👉 If you don’t calculate core density, you don’t know your real container cost.

In the next block, we will break this math into a direct 40HQ comparison — showing exactly how acacia, styrax, and eucalyptus cores translate into very different CBM outcomes inside the same container.

🔹 7️⃣ 40HQ Container Comparison: Acacia vs Styrax vs Eucalyptus

When plywood leaves the factory gate, the container becomes the real judge of profitability. From the export operations of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, we can confirm one fact without exception: core selection directly decides how much value fits inside a 40HQ container.

Below is not a theoretical comparison — it is based on factory loading practice, weight limits, and real export data.

🚢 Real 40HQ Loading Capacity by Core Type

| Plywood Core Type | Average Density (kg/cbm) | Typical Load per 40HQ | Export Reality |

|---|---|---|---|

| Acacia Core | 550–580 | ~54 CBM / 40HQ | Best volume balance |

| Styrax Core | 480–500 | ~47 CBM / 40HQ | Weight-optimized |

| Eucalyptus Core | 650–750 | ~42 CBM / 40HQ | Strength-driven |

These figures reflect payload-safe loading, not aggressive estimates that risk overweight penalties at port.

📉 How Buyers Unknowingly Lose Margin

Many buyers focus on FOB price per CBM, but ignore this simple reality:

- 🚢 Freight is paid per container

- 📦 Profit is earned per CBM landed

- ⚖️ Weight limits cap CBM before space is full

Choosing the wrong core can mean:

- ❌ Paying the same freight for fewer CBM

- ❌ Higher freight cost per CBM

- ❌ Reduced resale margin in Europe

- ❌ Lower competitiveness versus better-optimized suppliers

For example, comparing eucalyptus core to acacia core:

- Same 40HQ freight cost

- ~12 CBM less cargo

- Significantly higher landed cost per CBM

🧮 Factory Math vs Trading Assumptions

From the factory side of HCPLY – Vietnam Plywood, container planning always starts with:

- ⚖️ Core density

- 📦 Bundle weight

- 🚢 Payload compliance

- 📊 Landed cost optimization

Trading descriptions often say:

- “Strong core”

- “Heavy-duty plywood”

- “High density”

But factory math asks only one question:

👉 How many CBM can safely ship in one container?

🏭 Export Insight from HCPLY – Vietnam Plywood

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY uses container math to guide buyers toward:

- Acacia core for volume-driven imports

- Styrax core for weight-sensitive furniture markets

- Eucalyptus core only where strength justifies freight loss

This is why professional buyers increasingly ask for density data and container calculations before confirming orders.

In the next block, we will go one step further — connecting these loading differences to total landed cost, where FOB price alone completely loses its meaning.

🔹 8️⃣ Core Choice vs Total Landed Cost (Not Just FOB Price)

One of the biggest misconceptions in plywood sourcing is believing that FOB price equals cost competitiveness. From the export accounting and container planning perspective of HCPLY – Vietnam Plywood, a leading Vietnam plywood manufacturer, supplier, and exporter, this assumption consistently leads buyers to make expensive mistakes.

💵 Core Price Difference vs Freight Reality

Different plywood cores come with different raw material costs per CBM:

- Acacia: lower material cost, balanced density

- Styrax: mid-range material cost, lightweight advantage

- Eucalyptus: highest material cost, highest density

But FOB price per CBM tells only part of the story.

What truly matters is:

- 🚢 Freight cost per container

- 📦 CBM actually loaded per container

- 💰 Landed cost per CBM in Europe

A plywood core that looks “cheaper” at FOB level can easily become more expensive after freight is allocated.

📊 Why Cheaper Core ≠ Cheaper Landed Cost

From real export data at HCPLY – Vietnam Plywood, the pattern is clear:

- Higher-density cores load fewer CBM per container

- Freight cost is spread over fewer CBM

- Landed cost per CBM increases silently

This means:

- ❌ Buyers pay the same ocean freight

- ❌ Receive less sellable volume

- ❌ Lose margin without realizing why

In contrast, a slightly higher FOB-priced core with better loading efficiency can result in:

- 📉 Lower freight cost per CBM

- 📈 Better landed cost competitiveness

- 💼 Stronger resale margins in EU markets

🧮 Factory Insight: How HCPLY Calculates Real Cost

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY evaluates cost using:

- 📐 Core density (kg/cbm)

- 🚢 CBM per 40HQ container

- 💵 Ocean freight per container

- 📦 Freight allocation per CBM

- 📊 Final landed cost, not headline FOB

This factory-level calculation often reveals that:

- Styrax or acacia cores outperform eucalyptus on landed cost

- The “strongest” core is not the “most profitable” core

- Container math matters more than unit price comparisons

⚠️ The Hidden Margin Erosion Buyers Overlook

Many buyers compare supplier offers line by line:

- Same thickness

- Same face veneer

- Similar FOB price

Yet after arrival:

- Margins are thinner than expected

- Freight costs feel disproportionately high

- Competitors selling lighter-core plywood win on price

This erosion does not come from poor negotiation — it comes from choosing the wrong core.

🏭 Export Guidance from HCPLY – Vietnam Plywood

As a leading Vietnam plywood manufacturer and exporter, HCPLY advises buyers to:

- Compare landed cost per CBM, not FOB price

- Ask for core density and container loading data

- Select core based on end-market margin, not habit

- Treat plywood core selection as a financial decision, not just a technical one

In the next block, we will connect cost logic to real-world applications, showing how different plywood cores perform best in furniture, construction, and industrial use cases.

🔹 9️⃣ Core Selection by Application Type

From the manufacturing and export perspective of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, plywood core selection should never start from habit or past orders. It must start from end-use application, because each application places very different demands on weight, strength, surface quality, and cost structure.

🪑 Furniture & Interior Plywood

For furniture and interior applications, the priorities are:

- 🎨 Surface appearance

- ⚖️ Lightweight finished products

- 📐 Dimensional stability

- ✂️ Clean cutting and finishing

Recommended cores:

- ✅ Styrax (White Core) – preferred choice

- ✅ Acacia Core – acceptable for cost-controlled furniture

Why:

- Styrax delivers lighter panels and superior surface compatibility for poplar, birch, and okoume faces

- White core minimizes visual defects after cutting and sanding

- Better freight efficiency for furniture exporters targeting EU markets

From export data at HCPLY – Vietnam Plywood, most EU furniture buyers explicitly specify styrax core once surface quality becomes a priority.

🏗️ Construction & Structural Plywood

Construction and structural uses prioritize:

- 🧱 Load-bearing strength

- 🏗️ Compression resistance

- 📏 Panel rigidity

- 🌧️ Performance under stress and moisture exposure

Recommended cores:

- ✅ Eucalyptus Core – strength-driven choice

- ⚠️ Acacia Core – for medium-duty construction

Why:

- Eucalyptus provides the highest mechanical strength

- Better suited for structural and heavy-duty requirements

- Weight and freight efficiency are secondary to performance

As a Vietnam plywood manufacturer exporting structural plywood, HCPLY – Vietnam Plywood positions eucalyptus core only where strength is technically justified.

🏭 Film Faced & Industrial Plywood

Industrial and film faced plywood must balance:

- 🧱 Structural strength

- 🚧 Repeated use performance

- 🚢 Container loading efficiency

- 💰 Cost control at scale

Recommended cores:

- ✅ Acacia Core – most common and balanced choice

- ⚠️ Eucalyptus Core – for heavy-duty formwork only

Why:

- Acacia offers strong bonding and stable performance

- Better CBM loading per container than eucalyptus

- Lower landed cost for large-volume imports

This is why acacia remains the volume driver for film faced plywood exported by HCPLY – Vietnam Plywood.

🎯 Matching Core to End-Use, Not Habit

One of the most common mistakes HCPLY sees from new buyers is:

- Using eucalyptus “because it sounds stronger”

- Avoiding styrax “because it feels too light”

- Choosing acacia without understanding surface needs

From a factory and exporter viewpoint, these habits often lead to:

- ❌ Overpaying for unnecessary strength

- ❌ Higher freight cost

- ❌ Surface complaints or margin loss

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY emphasizes one rule across all applications:

👉 The right plywood core is defined by end-use — not by tradition, assumption, or generic trading terms.

In the next block, we will look at real European buyer preferences, showing how the EU market actually chooses between acacia, styrax, and eucalyptus in practice.

🔹 🔟 European Buyer Preferences: What the Market Really Chooses

After exporting plywood to Europe for many years, HCPLY – Vietnam Plywood sees a clear pattern: European buyers do not choose plywood cores randomly. Their preferences are shaped by regulations, freight economics, surface expectations, and long-term market positioning — not by generic strength claims.

As a Vietnam plywood manufacturer, direct supplier, and exporter with large production capacity, HCPLY works directly with EU importers, distributors, and OEM factories, giving us a clear view of what the market actually orders — not what it claims to prefer.

🇪🇺 Why EU Buyers Favor Styrax for Furniture-Grade Plywood

For furniture and interior applications, European buyers overwhelmingly lean toward styrax (white core) because it aligns with their core priorities:

- 🪑 Lightweight finished furniture

- 🎨 Clean, bright surface under thin veneers

- ✂️ Low defect visibility after cutting and sanding

- 🚢 Better container weight efficiency

From HCPLY – Vietnam Plywood export data:

- Styrax is most frequently specified for poplar, birch, okoume face plywood

- Common in OEM furniture projects and branded interior panels

- Preferred by buyers selling into premium or mid-high EU segments

For these buyers, surface quality and consistency outweigh raw strength, making styrax core the strategic choice.

🏗️ Why Eucalyptus Is Used Selectively, Not Universally

Although eucalyptus offers the highest strength, European buyers use it only when the application clearly demands it:

- Structural plywood

- Load-bearing or stress-intensive uses

- Certain industrial or formwork requirements

However, HCPLY – Vietnam Plywood consistently sees that:

- ❌ Eucalyptus is avoided for furniture

- ❌ Rarely chosen for decorative panels

- ❌ Often rejected once freight math is understood

EU buyers are highly cost-aware at landed level. If strength does not directly add value, eucalyptus core is seen as over-engineered and inefficient.

📦 How Acacia Remains the Volume Driver

Despite growing interest in styrax, acacia core remains the largest-volume core exported from Vietnam to Europe. The reason is simple:

- ⚖️ Balanced density

- 💰 Competitive FOB pricing

- 🚢 Acceptable container loading efficiency

- 🧱 Reliable bonding and structural stability

From the perspective of HCPLY – Vietnam Plywood, acacia is the go-to solution for:

- Commercial plywood

- Film faced plywood

- Mixed-use EU imports

- Buyers prioritizing volume and margin stability

Acacia does not dominate because it is trendy — it dominates because it works at scale.

🧠 What This Tells Us About the EU Market

European buyers are not chasing the “strongest” or “cheapest” plywood. They are choosing:

- ✔️ Styrax for appearance-driven products

- ✔️ Acacia for volume-driven imports

- ✔️ Eucalyptus only when strength is mandatory

As a leading Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY aligns production and export strategy around these real preferences — not assumptions.

In the next block, we will connect these market choices to core compatibility with face veneers, explaining why the right core-face pairing is critical for surface performance and buyer satisfaction.

🔹 1️⃣1️⃣ Core Compatibility with Face Veneers

From the factory production lines of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, one rule is consistently proven by real output data: face veneer quality can only perform as well as the core beneath it. Core–face compatibility is not a cosmetic detail — it is a structural and surface-critical decision.

🎨 Why Core Choice Directly Affects Face Veneer Results

Even with the same face veneer species, different cores will produce different final outcomes:

- Surface flatness after pressing

- Color consistency after sanding

- Risk of core shadowing or telegraphing

- Long-term dimensional stability

This is why professional buyers increasingly specify both face veneer and core type when sourcing from a Vietnam plywood manufacturer like HCPLY – Vietnam Plywood.

🌳 Poplar Face Veneer

Key priorities: light color, smooth finish, visual consistency

Best core matches:

- ✅ Styrax (White Core) – optimal match

- ⚠️ Acacia Core – acceptable with thicker face veneer

Factory insight from HCPLY – Vietnam Plywood:

- White core prevents dark color bleed-through

- Cleaner sanding results for furniture-grade panels

- Preferred by EU furniture and interior brands

🌲 Birch Face Veneer

Key priorities: premium appearance, uniform tone, high sanding precision

Best core matches:

- ✅ Styrax (White Core) – strongly recommended

- ⚠️ Acacia Core – only for cost-controlled projects

Why white core matters:

- Birch faces are often thin and unforgiving

- Dark or mixed cores increase rejection risk

- Styrax ensures visual stability across large batches

From export experience at HCPLY – Vietnam Plywood, most EU buyers pairing birch face with non-white cores eventually face surface inconsistency complaints.

🌴 Okoume Face Veneer

Key priorities: decorative appearance, light reddish tone, premium finishing

Best core matches:

- ✅ Styrax (White Core) – premium solution

- ✅ Acacia Core – widely used for balanced cost

Factory perspective:

- Styrax enhances surface brightness and uniformity

- Acacia provides stronger internal bonding for mixed-use panels

- Core selection depends on target market positioning

🌿 Bintangor Face Veneer

Key priorities: stability, moderate appearance, cost control

Best core matches:

- ✅ Acacia Core – most common choice

- ⚠️ Eucalyptus Core – only when strength is required

Export reality from HCPLY – Vietnam Plywood:

- Acacia delivers consistent bonding and cost efficiency

- White core advantage is less critical due to darker face tone

🌳 Gurjan Face Veneer

Key priorities: strength, durability, heavy-duty perception

Best core matches:

- ✅ Eucalyptus Core – strength-driven applications

- ✅ Acacia Core – balanced alternative for cost-sensitive buyers

Factory insight:

- Gurjan face is thick and robust

- Core color is less visible

- Structural performance often outweighs surface concerns

🏭 Factory Bonding & Sanding Considerations

From production control at HCPLY – Vietnam Plywood, core–face compatibility directly affects:

- 🧪 Glue absorption balance

- 🔥 Pressing pressure and cycle stability

- 🧽 Sanding tolerance without core exposure

- 📉 Rejection rate in large export batches

This is why HCPLY – Vietnam Plywood, as a Vietnam plywood manufacturer and plywood core Vietnam supplier, never recommends face veneers in isolation. Every export-grade panel is designed as a core + face system, optimized for EU expectations.

In the next block, we will shift from surface performance to compliance — examining how core selection influences EUDR / EUTR risk and traceability strategy for European buyers.

🔹 1️⃣2️⃣ Core Choice & EUDR / EUTR Risk Perspective

For European buyers today, plywood core selection is no longer only a technical or cost decision — it is a compliance and risk management decision. From the exporter and compliance-handling perspective of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, core choice directly influences how easily a shipment can pass EUTR and EUDR due diligence.

🌱 Plantation Sourcing vs Natural Forest Risk

European regulations increasingly focus on origin transparency, not just finished product quality.

From factory and sourcing control at HCPLY – Vietnam Plywood:

- 🌱 Acacia: almost entirely plantation-grown in Vietnam

- 🌱 Styrax (Alstonia scholaris): plantation-sourced, controlled harvesting

- 🌱 Eucalyptus: plantation-based, but with stricter traceability expectations

This matters because:

- Plantation wood carries lower deforestation risk

- Harvest cycles are documented and predictable

- Legal origin is easier to demonstrate during audits

Cores with unclear or mixed sourcing automatically increase compliance burden and buyer risk.

📜 Traceability Differences by Core Species

From real EUTR / EUDR file preparation experience at HCPLY – Vietnam Plywood, traceability strength varies by core:

Acacia Core

- ✔️ Widely documented plantation supply chains

- ✔️ Easier FSC or controlled wood alignment

- ✔️ Lower document complexity for EU buyers

Styrax (White Core)

- ✔️ Plantation-origin verification is straightforward

- ✔️ Often favored in furniture supply chains due to clean traceability

- ✔️ Lower risk perception for decorative and interior panels

Eucalyptus Core

- ⚠️ Strong traceability required due to higher scrutiny

- ⚠️ More documentation expected for volume exports

- ✔️ Acceptable when plantation sourcing is clearly proven

As a Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY structures sourcing and documentation by species, not generically.

⚠️ Why Core Selection Affects Compliance Strategy

Many buyers underestimate this point:

- EUDR does not evaluate plywood as a single object

- It evaluates each wood species inside the product

This means:

- Mixed or misdeclared cores create red flags

- Vague descriptions like “hardwood core” increase audit risk

- Species-specific traceability becomes mandatory

At HCPLY – Vietnam Plywood, core transparency is treated as a compliance shield, not a marketing claim.

🏭 Factory-Controlled Cores vs Trading Risk

From exporter audits and buyer feedback, one pattern is clear:

- Traders often rely on third-party declarations

- Core species may be mixed or inconsistently declared

- Documentation gaps appear only when buyers are audited

By contrast, HCPLY – Vietnam Plywood, as a direct Vietnam plywood manufacturer:

- Controls veneer sourcing at factory level

- Maintains species-specific sourcing records

- Aligns production batches with traceability files

- Supports EU buyers during EUTR / EUDR review

🧠 Compliance Insight from HCPLY – Vietnam Plywood

From a risk management perspective, HCPLY advises EU buyers:

- Choose plantation-based cores whenever possible

- Avoid vague or mixed-core specifications

- Match core species with traceability strength

- Treat plywood core selection as part of EUDR strategy, not just procurement

As a leading Vietnam plywood manufacturer and exporter, HCPLY integrates core selection, sourcing control, and compliance documentation into one unified export process.

In the next block, we will translate this technical and regulatory insight into practical recommendations by buyer profile, showing how different importers should choose the right core based on strategy, not guesswork.

🔹 1️⃣3️⃣ What HCPLY Recommends Based on Buyer Profiles

After years of exporting plywood to Europe, HCPLY – Vietnam Plywood has learned that there is no “best plywood core” — only the right core for the right buyer profile. As a large-scale Vietnam plywood manufacturer, supplier, and exporter, HCPLY does not recommend cores generically. We recommend them strategically, based on how buyers actually make money in their market.

💶 Price-Focused Importers (Trading Companies & Volume Buyers)

Core recommendation:

- ✅ Acacia Core (primary choice)

- ⚠️ Styrax Core (when surface quality is slightly prioritized)

Why HCPLY recommends this:

- ⚖️ Balanced density keeps freight cost under control

- 💰 Competitive FOB pricing at factory scale

- 📦 High CBM loading efficiency per 40HQ

- 🧱 Stable bonding performance with low production risk

From the export data of HCPLY – Vietnam Plywood, acacia core delivers the best margin protection for importers competing on price in Europe while still meeting standard quality expectations.

🏷️ Brand-Focused EU Distributors

Core recommendation:

- ✅ Styrax (White Core)

Why this profile fits styrax best:

- 🎨 Clean surface appearance under light face veneers

- ⚖️ Lightweight panels improve downstream logistics

- ✂️ Lower rejection rate after cutting and finishing

- 📊 Consistent quality across large branded batches

For distributors selling under their own brand, appearance complaints are more expensive than a higher FOB price. This is why HCPLY – Vietnam Plywood consistently supplies styrax core to EU buyers building long-term brand value.

📄 Long-Term Contract Buyers & Framework Agreements

Core recommendation:

- ✅ Acacia Core (standardized)

- 🔁 Styrax Core (for furniture-grade lines)

HCPLY factory rationale:

- 📈 Stable raw material availability

- 🔄 Predictable production scheduling

- 📦 Reliable container planning

- 📜 Easier documentation and compliance repetition

As a Vietnam plywood manufacturer operating at scale, HCPLY – Vietnam Plywood prioritizes cores that can be reproduced consistently year after year, minimizing risk for both factory and buyer.

🪑 OEM Furniture Producers

Core recommendation:

- ✅ Styrax (White Core)

- ⚠️ Acacia Core (only when surface tolerance allows)

Why OEMs choose styrax:

- 🎯 Surface perfection under thin veneers

- ⚖️ Lightweight finished furniture

- 🧽 Better sanding behavior

- 📉 Reduced rejection and rework costs

From HCPLY’s export experience, OEM furniture producers value process stability more than raw strength, making styrax core the preferred solution.

🏗️ Structural & Industrial Buyers

Core recommendation:

- ✅ Eucalyptus Core (application-driven only)

When HCPLY approves eucalyptus use:

- 🧱 Load-bearing or stress-intensive applications

- 🏗️ Structural or industrial performance requirements

- 📐 Strength clearly outweighs freight inefficiency

As a responsible Vietnam plywood manufacturer, HCPLY – Vietnam Plywood actively discourages eucalyptus core when strength does not add real value — even if buyers initially request it.

🧠 Strategic Advice from HCPLY – Vietnam Plywood

Across all buyer profiles, HCPLY follows one principle:

- ❌ Do not overspecify strength

- ❌ Do not chase the lowest FOB blindly

- ✅ Optimize for landed cost, surface performance, and compliance

This is why HCPLY – Vietnam Plywood, as a leading Vietnam plywood manufacturer and plywood core Vietnam supplier, positions itself not just as a supplier — but as a long-term sourcing partner.

In the next block, we will address a critical risk area many buyers underestimate: why core transparency matters more than marketing claims.

🔹 1️⃣4️⃣ Why Core Transparency Matters More Than Marketing Claims

In today’s plywood trade, marketing language has become dangerously vague. From the real-world export and claim-handling experience of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, we can state clearly: most plywood problems do not come from poor face veneer — they come from unclear or misrepresented cores.

🎭 Trading Descriptions vs Factory-Controlled Reality

Common trading terms often seen in offers:

- “Hardwood core”

- “Strong mixed core”

- “Premium core plywood”

- “Export quality core”

From a factory standpoint, these descriptions mean almost nothing.

At HCPLY – Vietnam Plywood, core transparency means:

- ✅ Declared wood species

- ✅ Measured density range

- ✅ Controlled veneer composition

- ✅ Traceable sourcing records

- ✅ Repeatable production parameters

Anything less introduces uncertainty, risk, and hidden cost for the buyer.

⚠️ The Risk of Mixed or Misdeclared Cores

One of the most common issues seen by HCPLY in buyer complaints is core inconsistency:

- Mixed species inside one panel

- Different densities across shipments

- Substitution without buyer awareness

- Inconsistent glue absorption and pressing behavior

These risks often surface after delivery, when:

- Panels sand unevenly

- Weight per pallet exceeds expectations

- Surface defects appear after cutting

- Compliance audits request species-level data

By then, FOB savings are irrelevant.

🧾 Why Transparency Is Now a Commercial Advantage

European buyers today face:

- Tighter compliance audits

- Higher freight sensitivity

- Lower tolerance for quality variance

In this environment, transparent core specification is no longer a technical detail — it is a commercial differentiator.

From HCPLY – Vietnam Plywood export experience:

- Buyers with clear core specs face fewer claims

- Repeat orders stabilize faster

- Long-term pricing becomes more predictable

- Compliance reviews become procedural, not stressful

🏭 Why Buyers Work Directly with Manufacturers

The shift we observe most clearly is this:

- Buyers move away from layered trading chains

- Buyers request factory-level core data

- Buyers want production accountability

As a direct Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY – Vietnam Plywood provides:

- Factory-controlled core selection

- Species-specific documentation

- Density and loading transparency

- Production consistency across contracts

This level of control is impossible when cores are sourced indirectly or changed opportunistically.

🧠 HCPLY Perspective: Transparency Is Risk Insurance

From a strategic viewpoint, HCPLY treats core transparency as:

- 🛡️ Protection against disputes

- 📦 Insurance for container loading assumptions

- 📜 Foundation for EUDR / EUTR compliance

- 🤝 Basis for long-term buyer trust

That is why HCPLY – Vietnam Plywood, as a leading Vietnam plywood manufacturer and exporter, does not compete on vague promises. We compete on measurable facts, factory data, and transparent core control.

In the final block, we will summarize everything into clear decision guidance, helping buyers confidently choose the right plywood core — and the right manufacturing partner.

🔹 1️⃣5️⃣ Final Guidance: Choosing the Right Core with HCPLY – Vietnam Plywood

After breaking down density, container math, landed cost, application fit, surface compatibility, and compliance risk, one conclusion becomes unavoidable: plywood core selection is the foundation of a successful import strategy. From the manufacturing and export perspective of HCPLY – Vietnam Plywood, a leading Vietnam plywood manufacturer, supplier, and exporter, the right core is not chosen by habit — it is chosen by logic.

🧭 Summary Decision Matrix (Factory Perspective)

- 🪵 Choose Acacia Core if you need:

- Competitive landed cost

- High CBM per 40HQ container

- Stable bonding and scalable volume

- Commercial, film faced, or mixed-use plywood

- Reliable, repeatable production from a Vietnam plywood manufacturer

- 🌲 Choose Styrax (White Core) if you need:

- Lightweight panels

- Premium surface appearance

- Clean sanding and finishing

- Furniture-grade plywood for EU markets

- Lower visual and rejection risk

- 🌴 Choose Eucalyptus Core if you truly need:

- Maximum strength and rigidity

- Structural or industrial performance

- Load-bearing capability where strength adds real value

- Acceptance of lower CBM loading and higher freight cost

⚠️ What Buyers Should Avoid

From real export experience at HCPLY – Vietnam Plywood, buyers should avoid:

- ❌ Selecting cores based only on FOB price

- ❌ Over-specifying strength without end-use justification

- ❌ Accepting vague descriptions like “hardwood core”

- ❌ Ignoring container weight and landed cost math

These shortcuts consistently lead to higher risk, lower margins, and long-term sourcing instability.

🏭 Why Work with HCPLY – Vietnam Plywood

As a large-scale Vietnam plywood manufacturer and plywood core Vietnam supplier, HCPLY offers:

- Factory-controlled core selection

- Species-specific transparency

- Real density and container loading data

- EU-focused production and compliance understanding

- Stable quality, competitive pricing, and scalable capacity

We do not position ourselves as a short-term supplier. We position HCPLY – Vietnam Plywood as a manufacturing partner who helps buyers make decisions that protect margin, quality, and compliance — shipment after shipment.

🤝 Final Word from the Factory

Choosing the right plywood core is not about choosing acacia, styrax, or eucalyptus.

It is about choosing:

- The right performance level

- The right cost structure

- The right compliance path

- The right manufacturing partner

If you are sourcing plywood from Vietnam for Europe and want transparent core options, factory data, and export-proven guidance, HCPLY – Vietnam Plywood is ready to support your next project — from core selection to container loading to long-term supply planning.

👉 The right core starts at the factory. The right decision starts with HCPLY – Vietnam Plywood.

🔗 Explore HCPLY Product Pages – Apply the Right Core to the Right Plywood

Choosing the right plywood core only creates value when it is applied to the correct plywood product, produced at factory scale with controlled cores, stable quality, and export-proven performance.

As a leading Vietnam plywood manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood invites you to explore our product pages below — each optimized by acacia core, styrax (white core), or eucalyptus core, depending on application, EU market demand, and compliance requirements.

👉 Click to explore HCPLY product lines:

- 🪵 Bintangor Plywood Vietnam

Balanced acacia core solutions for commercial and interior applications. - 🌲 Birch Plywood Vietnam

Furniture-grade plywood with strict white core control for premium EU markets. - 🧩 Core Veneer Vietnam

Plantation-sourced acacia, styrax, and eucalyptus core veneers for plywood factories. - 🏗️ Film Faced Plywood Vietnam

High-bonding acacia core and heavy-duty eucalyptus core for construction and formwork. - 🌳 Gurjan Plywood Vietnam

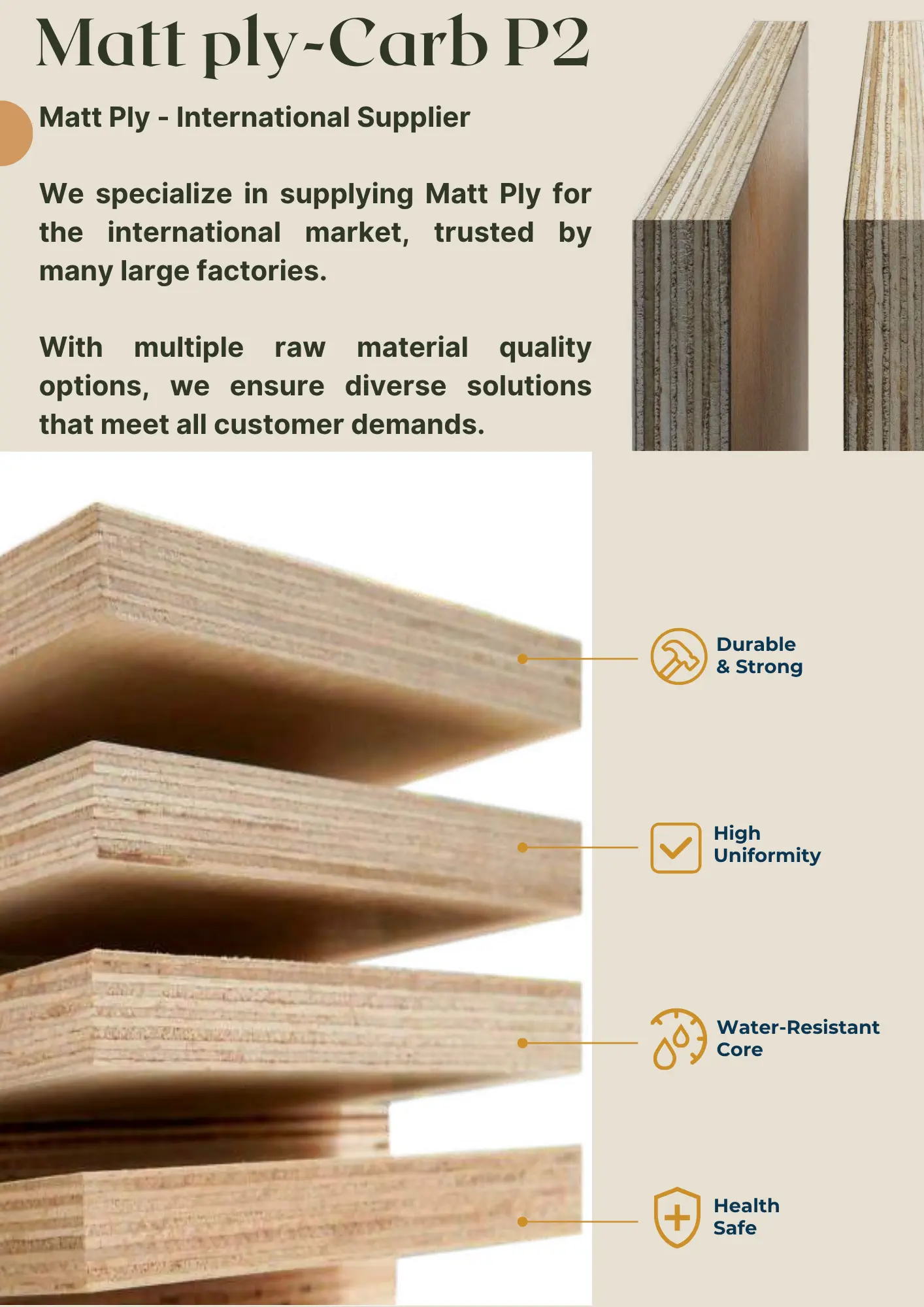

Strong face veneer combined with acacia or eucalyptus core for durability-focused buyers. - 🧱 Matt Plywood Vietnam

Core-only plywood optimized for lamination and face veneering applications. - 🌿 Okoume Plywood Vietnam

Premium decorative plywood paired with white core or balanced acacia core. - 📦 Packing Plywood Vietnam

Cost-efficient plywood with optimized core density for logistics and packaging use. - 🌲 Pine Plywood Vietnam

Lightweight plywood solutions with stable plantation-sourced cores. - 🪑 Poplar Plywood Vietnam

Furniture-grade plywood matched with styrax (white core) for surface perfection. - 🌴 Eucalyptus Plywood Vietnam

High-strength plywood for structural and industrial requirements. - 🌿 EV Plywood Vietnam

Engineered veneer plywood with controlled core structure and export consistency. - 🚧 Anti Slip Plywood Vietnam

Industrial flooring plywood with strength-driven core selection.

Each product page reflects real factory data, real core selection, real container loading math, and real EU export experience — not generic trading descriptions.

If you want to discuss which plywood product and core combination best fits your market, HCPLY – Vietnam Plywood is ready to support you as a direct manufacturer and exporter with large capacity, stable quality, and competitive pricing.

👉 Choose the product. Choose the core. Choose the manufacturer.