Table of contents

Okoume face Plywood Vietnam — The Complete Export Guide (2025)

Vietnam has rapidly established itself as a global leader in plywood manufacturing. Among its key export products, Okoume Face Plywood Vietnam stands out for its combination of beauty, strength, and sustainability. This complete export guide provides detailed insights into production, structure, certification, and market strategies for 2025 — helping global importers understand why Vietnam’s Okoume plywood has become a preferred choice in Europe, the Middle East, and beyond.

🪵 1. The Global Rise of Okoume Face Plywood Vietnam in 2025

Over the last decade, Okoume Face Plywood Vietnam has transformed from a niche decorative material into one of the most sought-after export plywood categories worldwide. In 2025, it stands as a cornerstone of Vietnam’s wood industry — bridging African raw materials with Vietnamese engineering precision and export expertise.

The outer veneer of Okoume, sourced mainly from Gabon and the Republic of Congo, is prized for its silky pinkish hue and uniform fiber structure. When bonded with locally sourced eucalyptus, acacia, or mixed hardwood cores, it forms a plywood that achieves the perfect synergy between beauty, strength, and affordability. Unlike local Asian softwood plywoods, Okoume-faced panels combine lightweight density (480–530 kg/m³) with exceptional dimensional stability — a quality that appeals to both European furniture producers and Middle Eastern construction buyers.

At the heart of this success are Vietnamese manufacturers such as HCPLY – Vietnam Plywood Manufacturer & Supplier, who have perfected the art of veneer calibration, hot-pressing, and edge balancing. Each Okoume Face Plywood panel undergoes multi-stage moisture control, ensuring that the core humidity never exceeds 12%, preventing warping during long-distance sea freight. The result is a plywood that retains shape, tone, and bonding integrity even after months in transit or storage.

Beyond technical excellence, Okoume Plywood Vietnam has also become synonymous with sustainability and compliance. Certified under FSC®, CARB P2, and CE EN13986, it meets the strict environmental and safety requirements demanded by European and American importers. Factories use formaldehyde-free adhesives and invest in eco kiln-drying systems, aligning production with the low-emission goals of global furniture supply chains.

From Paris to Dubai, importers are now viewing Vietnamese Okoume plywood not just as a building material, but as an aesthetic foundation for design — one that captures both the warmth of natural wood and the reliability of advanced engineering. As the demand for environmentally responsible, visually refined, and export-stable plywood continues to rise, Okoume Face Plywood Vietnam is positioning itself as the defining product for the next generation of global plywood trade.

🪵 2. Understanding Okoume Face Plywood Structure and Core Technology

The structure of Okoume Face Plywood Vietnam is more than just an assembly of veneers — it represents a carefully engineered balance between natural aesthetics and industrial stability. The face veneer, typically 0.3–0.6 mm thick, is sliced from genuine Okoume wood (Aucoumea klaineana), known for its rich reddish tone and even grain. This top layer gives furniture, doors, and decorative panels a premium, luxurious look while keeping the material cost-effective compared to full Okoume solid timber.

Beneath the face layer lies the core system, which defines the panel’s performance. Vietnamese factories like HCPLY – Vietnam Plywood Manufacturer & Supplier use three main types of cores:

- Eucalyptus core: providing high stiffness and impact resistance, ideal for structural applications.

- Acacia or mixed hardwood core: balancing flexibility and cost, suitable for furniture substrates.

- Poplar or keo core: offering lightweight composition for export markets that prioritize ease of handling and transportation.

Each core layer is bonded using melamine or phenolic resin, with glue spreads controlled at 5–15% depending on usage requirements. During manufacturing, the veneers undergo hot-pressing at 120–140°C, ensuring uniform adhesion and a consistent moisture barrier. The pressing time and temperature are adjusted according to the core’s density — a detail that distinguishes high-end Vietnamese plywood from low-quality regional substitutes.

Moreover, Okoume Face Plywood is calibrated to achieve flatness tolerances under 0.3 mm per square meter. After pressing, every panel passes through a multi-step sanding and trimming process, ensuring clean edges and ready-to-laminate surfaces. This meticulous preparation allows global buyers to apply decorative coatings or laminates directly, without additional surface work — saving labor, time, and cost.

In 2025, the global demand for Okoume face plywood Vietnam is increasingly driven by the shift toward lightweight yet durable materials for furniture exports to Europe, the Middle East, and North America. With advanced core composition, optimized veneer alignment, and eco-friendly adhesives, Vietnamese factories are setting a new benchmark in plywood craftsmanship that rivals even long-established European producers.

🪵 3. The Okoume Veneer Selection and Grading Process in Vietnam

Selecting the right Okoume veneer is the foundation of producing world-class Okoume Face Plywood Vietnam. The veneer acts not only as a visual surface but also as a defining layer that determines the final product’s quality, color harmony, and aesthetic appeal. Vietnamese manufacturers, especially HCPLY, follow a multi-stage veneer inspection and grading system aligned with international export standards (A/B/C grades) to ensure uniformity and beauty across every sheet.

Veneer Origin and Import Standards

Most Okoume veneer used in Vietnam is imported from Gabon, Equatorial Guinea, and the Republic of Congo, where Okoume trees are sustainably harvested under FSC® certification. Once imported, the veneers are kiln-dried to a consistent moisture level of 8–10% to prevent surface cracking or discoloration during lamination. Each batch undergoes visual inspection for grain uniformity, absence of knots, and surface brightness.

Grading and Sorting System

Vietnamese factories apply an internal grading code system:

- Grade A: Uniform color tone, no open defects, minimal pin knots — used for high-end furniture and export panels.

- Grade B: Slight shade variation, minor repaired areas — suitable for door skins and cabinet interiors.

- Grade C: More visible grain variation — used for construction or non-visible furniture components.

Technicians examine each veneer under daylight-balanced LED lighting to detect subtle color shifts. Veneers are then color-matched and sequenced before pressing to achieve a consistent flow of texture across panels — a signature of high-end Okoume plywood craftsmanship.

Surface Preparation and Cutting Precision

The veneer sheets are trimmed using laser-guided guillotines to maintain edge accuracy within ±0.2 mm. Before lamination, surfaces are cleaned with compressed air to remove dust, ensuring strong adhesion with the glue line. The bonding process involves uniform glue spread using a roller coater system, which helps maintain even penetration and prevents surface bubbling.

This meticulous approach to veneer selection and grading gives Okoume Face Plywood Vietnam its signature elegance — a clean, natural, and balanced appearance that rivals European standards. Each board reflects Vietnam’s manufacturing discipline: from sourcing African veneers ethically to transforming them into premium export-ready plywood that defines quality in 2025.

🪵 4. Manufacturing Workflow of Okoume Face Plywood Vietnam

The manufacturing process of Okoume Face Plywood Vietnam is a meticulously engineered workflow designed to ensure strength, consistency, and beauty in every sheet. From veneer preparation to hot pressing and final sanding, each phase is monitored with precise quality control protocols that meet international export standards.

Step 1: Veneer Preparation and Moisture Conditioning

The process begins with core veneer selection, typically made from eucalyptus or acacia wood. These veneers are peeled, trimmed, and then kiln-dried to reduce moisture to 8–12%. Proper moisture balance is critical — over-dried cores become brittle, while high-moisture veneers can cause delamination. Simultaneously, imported Okoume face veneers are acclimated in a humidity-controlled chamber to match Vietnam’s ambient production climate, preventing stress or cracking during pressing.

Step 2: Glue Application and Lay-Up Assembly

Factories such as HCPLY utilize advanced roller glue spreaders to apply melamine or phenolic adhesives evenly at 180–220 g/m² per surface. This precision ensures strong interlayer bonding without over-gluing, which could cause bubbling or uneven thickness. Veneers are assembled in alternating grain directions (cross-grain construction), optimizing dimensional stability and reducing panel warping. Each plywood lay-up consists of 3, 5, 7, or 9 layers depending on thickness requirements — from 3.6 mm to 25 mm for export.

Step 3: Hot Pressing and Cold Setting

The stacked veneer packs are transferred to a multi-daylight hot press machine operating between 120–140°C and 0.9–1.2 MPa pressure. The duration of each press cycle varies by panel thickness but typically lasts 5–12 minutes. This process activates resin polymers, creating permanent adhesion between veneers. After hot pressing, the boards are cooled naturally or through cold press systems to stabilize the internal stresses, maintaining flatness and bond integrity.

Step 4: Trimming, Sanding, and Calibration

Pressed boards are trimmed using automated double-end saws, ensuring consistent dimensions (tolerance ±0.5 mm). They then pass through wide-belt sanding machines using 180–320 grit belts for a smooth, defect-free surface. High-precision calibration sanding ensures even thickness, a crucial factor for furniture producers who require tight tolerances for CNC cutting and lamination.

Step 5: Quality Inspection and Packaging

Each sheet undergoes detailed inspection — checking for surface defects, glue line visibility, and edge flatness. Panels are tested for bonding strength (≥1.0 MPa for MR glue, ≥1.2 MPa for phenolic) and water resistance through 24-hour immersion tests. Only boards meeting strict export specifications are stamped with factory batch codes and wrapped in moisture-proof film packaging with corner protection.

By the time Okoume Face Plywood Vietnam leaves the factory floor, it has undergone a production journey blending science, craftsmanship, and sustainability. Every phase — from raw veneer conditioning to final inspection — reflects Vietnam’s growing mastery in delivering plywood that competes with European-grade materials while maintaining Asia’s most competitive export pricing.

🪵 5. Export Standards and Quality Certifications for Okoume Face Plywood Vietnam

In 2025, export compliance and quality certification have become critical differentiators for Okoume Face Plywood Vietnam in the global marketplace. Buyers across Europe, the Middle East, and North America no longer assess plywood solely on appearance or strength — they demand verified documentation of environmental sustainability, emissions safety, and manufacturing traceability. Vietnamese factories, led by HCPLY, have responded with an integrated quality management system that aligns with both Western import standards and the evolving sustainability frameworks of global trade.

FSC® and Legal Timber Compliance

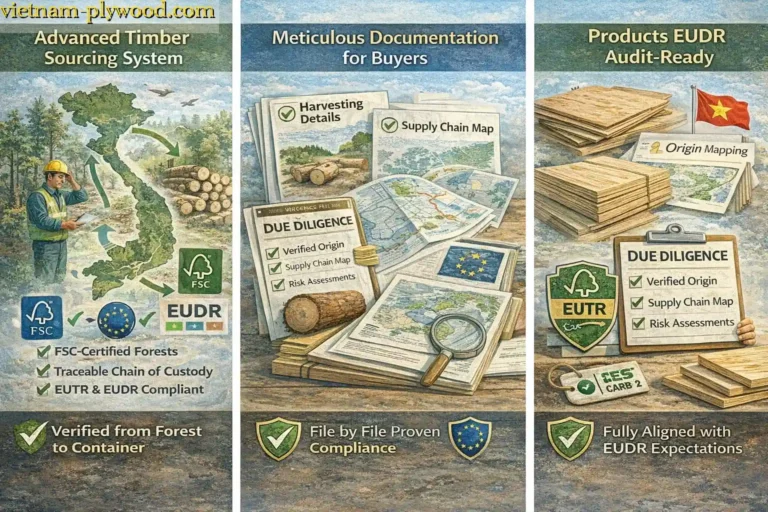

All Okoume veneers imported from Africa undergo legality verification under the Forest Stewardship Council (FSC®) or PEFC™ systems, ensuring the wood originates from responsibly managed forests. Vietnam’s plywood exporters must maintain a Chain of Custody (CoC) system to trace every batch of veneer from port entry to finished product shipment. This certification allows exporters to meet the EU Timber Regulation (EUTR), UKTR, and U.S. Lacey Act requirements — preventing illegal logging and boosting international trust in Vietnamese wood products.

CARB Phase 2 and E0 Formaldehyde Emission Standards

To serve sensitive markets like California, Japan, and the EU, Okoume Face Plywood Vietnam manufacturers adhere to CARB P2 (California Air Resources Board Phase 2) and E0 emission limits, which cap formaldehyde release to less than 0.05 ppm. Many factories utilize formaldehyde-free melamine or soy-based adhesives, tested and certified by SGS and TUV laboratories. These low-emission products qualify for use in baby furniture, kitchen interiors, and eco-conscious construction projects.

CE EN13986 and ISO Production Systems

Vietnamese plywood exporters targeting Europe must obtain CE EN13986 certification, which confirms that panels meet structural integrity and fire-safety standards for construction and furniture applications. HCPLY operates under ISO 9001:2015 and ISO 14001:2015, covering both quality control and environmental management systems. This dual compliance ensures each export batch maintains dimensional tolerance, bonding strength, and consistent thickness, while minimizing carbon footprint and energy waste.

Testing, Inspection, and Traceability

Every shipment of Okoume plywood undergoes third-party inspection before container loading. Tests include bonding strength, water boil test (WBP), thickness calibration, and surface grading. Each pallet is marked with a batch number and QR code, linking digital records of veneer origin, glue formulation, and pressing temperature. This traceability model gives buyers verifiable data for customs clearance, insurance, and after-sales documentation.

Global Acceptance and Market Advantage

Through rigorous adherence to international standards, Okoume Face Plywood Vietnam has evolved into one of the most recognized plywood brands in the export industry. Buyers from Italy, Saudi Arabia, and the United States increasingly cite Vietnam’s blend of ethical sourcing, precise engineering, and certification transparency as reasons for choosing it over Chinese or Malaysian suppliers. In essence, every certified panel represents not just compliance — but a commitment to long-term reliability, sustainability, and trade integrity that defines Vietnam’s plywood leadership in 2025.

| Certification Type | Standard Code | Description |

|---|---|---|

| FSC® | Chain of Custody | Legal and sustainable veneer sourcing |

| CARB P2 / E0 | Formaldehyde ≤ 0.05 ppm | Low-emission adhesive compliance |

| CE EN13986 | Construction safety standard | Conforms to EU building requirements |

| ISO 9001 / 14001 | Quality & Environment | Certified production management |

| SGS / TUV | Third-party verification | Independent lab-tested performance |

🪵 6. Global Market Trends and Export Outlook for Okoume Face Plywood Vietnam (2025–2030)

As global supply chains evolve toward sustainability and high-value customization, Okoume Face Plywood Vietnam is emerging as one of the most dynamic categories in the international wood trade. Between 2025 and 2030, demand forecasts show a steady annual growth rate of 7–9%, driven by strong consumption from furniture manufacturers, marine industries, and interior contractors in Europe, the Middle East, and North America.

Vietnam’s strategic advantage lies in its integrated ecosystem — from veneer import logistics at ports like Hai Phong and Quy Nhon to advanced processing hubs in Bac Giang, Binh Dinh, and Dong Nai. This structure allows Okoume Face Plywood Vietnam producers to maintain consistent quality and competitive pricing, even when global shipping or raw veneer costs fluctuate.

Expanding Demand in the EU and GCC Markets

In Europe, the market for lightweight decorative plywood is undergoing a shift from tropical hardwoods to verified, eco-friendly alternatives. With its FSC® certification, low-emission adhesives, and calibrated surface precision, Okoume Face Plywood Vietnam perfectly fits the preferences of importers in France, Italy, and Germany — countries traditionally reliant on Gabonese or Chinese panels.

Meanwhile, in the Gulf Cooperation Council (GCC) region, the rise of modular construction and high-end interiors in Saudi Arabia, the UAE, and Qatar has opened new doors for Vietnamese exporters who can deliver both Okoume face plywood and customized cut-to-size components.

Competitive Advantages of Vietnamese Exporters

Compared to other Asian suppliers, Vietnamese Okoume plywood factories combine automation with human expertise. Facilities equipped with Japanese hot-press systems, German sanding lines, and computerized moisture monitoring ensure each Okoume Face Plywood Vietnam sheet meets export standards while remaining cost-effective.

Factories such as HCPLY have built long-term partnerships with African veneer suppliers, ensuring stable raw material access — a crucial factor in achieving reliability across fluctuating seasons.

Price Stability and Supply Forecast

Despite rising global timber prices, Vietnam’s production efficiency and export incentives under trade agreements such as EVFTA and RCEP are expected to stabilize Okoume Face Plywood Vietnam pricing between USD 420–580 per cubic meter (FOB) through 2026. This predictability strengthens buyer confidence and helps importers plan bulk shipments with lower risk exposure.

Sustainability and Branding Outlook

By 2030, sustainability will be not just a compliance factor but a market identity. Vietnamese exporters are already positioning Okoume Face Plywood Vietnam as a “green premium” alternative — highlighting traceable origins, zero-deforestation sourcing, and energy-efficient production.

Global brands in furniture retail and yacht interiors increasingly prefer suppliers who can provide both beauty and accountability, giving Vietnam a strategic branding edge.

In conclusion, the next five years will define Vietnam’s leadership in the global plywood industry. With sustainable sourcing, advanced production, and strong trade networks, Okoume Face Plywood Vietnam is no longer a regional product — it is a global benchmark for engineered elegance, stability, and responsible manufacturing.

According to trade data from 2024–2025, Vietnam now supplies over 22% of the global Okoume-faced plywood market, ranking just behind China. The key destinations include France (28%), Saudi Arabia (17%), India (14%), and UAE (12%). This continuous export growth reflects Vietnam’s steady improvement in quality, consistency, and sustainable sourcing.

🪵 7. Logistics and Export Handling Process for Okoume Face Plywood Vietnam

The export logistics chain of Okoume Face Plywood Vietnam plays a decisive role in ensuring product integrity, shipping efficiency, and client satisfaction. In 2025, with Vietnam ranking among the top three plywood exporters in Asia, factories such as HCPLY have refined a comprehensive export system — from container packing to global freight coordination — that minimizes cost while maintaining delivery precision.

Export Preparation and Moisture Conditioning

Before any shipment, Okoume Face Plywood Vietnam panels undergo final moisture calibration in climate-controlled storage rooms. The target humidity is maintained between 8–12%, preventing expansion or delamination during sea voyages. Panels are stacked on fumigated wooden pallets, separated by moisture barriers and wrapped in heat-sealed plastic film. Each bundle includes edge protection and waterproof labeling to resist humidity variations through long-distance transport.

Packing and Containerization

Standard export packing for Okoume Face Plywood Vietnam follows the “flat stack” method to optimize cubic space and prevent bending.

- 20’GP container: fits approximately 25–27 m³ (≈ 16 pallets, 650–700 sheets).

- 40’HC container: holds up to 48–50 m³ (≈ 28–30 pallets, 1,100–1,200 sheets).

Bundles are secured using galvanized metal straps and corner protectors. For high-end orders, desiccant bags and vapor barriers are applied to control condensation during sea transit. The loading team uses forklift-guided alignment to distribute pallet weight evenly across the container floor, ensuring structural balance and preventing stress damage to the bottom layer.

Export Documentation and Quality Traceability

Each shipment of Okoume Face Plywood Vietnam is accompanied by a full set of export documents including:

- Commercial Invoice & Packing List

- Certificate of Origin (Form B, EUR.1, or REX)

- Fumigation Certificate & Phytosanitary Declaration

- Inspection Report (SGS, Intertek, or Bureau Veritas)

- FSC® or CARB P2 Certificates (if applicable)

Every pallet carries a printed QR code linking to the factory database that records veneer source, glue batch, pressing temperature, and moisture level — ensuring traceability and compliance with EUDR and Lacey Act requirements.

Shipping and Freight Options

Vietnam’s plywood exports primarily depart from Hai Phong, Qui Nhon, and Cat Lai ports. Depending on destination, buyers can choose:

- FCL Sea Freight (most common) – 30–40 days to Europe, 20–25 days to the Middle East, 12–18 days to India.

- LCL Consolidation for small orders below 10 m³.

- Air Freight for urgent deliveries (2–5 days), typically used for samples or special project panels.

HCPLY maintains long-term contracts with leading shipping lines such as Maersk, CMA-CGM, and ONE, providing stable freight rates and predictable sailing schedules even during peak export seasons.

Insurance and Risk Management

All Okoume Face Plywood Vietnam shipments are insured under ICC (A) terms, covering marine damage, handling errors, and humidity impact. Clients can opt for CIF (Cost, Insurance, Freight) or FOB (Free on Board) terms based on their trade agreement. Each container is photographed and sealed before departure; seal numbers and photos are included in the shipping dossier for verification upon arrival.

Delivery Assurance and After-Sales Coordination

Upon shipment arrival, HCPLY’s export team monitors customs clearance and provides online support for any claim regarding quantity or appearance variance. Replacement sheets or compensation policies are implemented within 10 working days after verification. This commitment to reliability reinforces Vietnam’s reputation as a trusted global supplier of Okoume face plywood — combining product quality with seamless international logistics.

In short, the export handling framework of Okoume Face Plywood Vietnam represents the fusion of precision manufacturing, disciplined packaging, and traceable logistics — guaranteeing that every panel reaches its destination in pristine condition, ready for lamination, furniture assembly, or architectural application.

Packaging Options for Different Markets

- Europe: Uses heavy-duty stretch film and waterproof kraft paper for humidity control.

- Middle East: Reinforced corner protection with UV-resistant wrapping.

- India: Light plastic wrap for domestic lamination factories to reduce waste.

- North America: Palletized with silica gel and steel strapping for long-distance sea freight.

These customized export packages ensure Okoume Face Plywood Vietnam arrives in perfect condition, regardless of destination.

🪵 8. Environmental Responsibility and Sustainable Practices in Okoume Face Plywood Vietnam

Sustainability lies at the heart of the global wood industry, and Okoume Face Plywood Vietnam has rapidly become a model for eco-conscious manufacturing. By 2025, Vietnamese plywood exporters — particularly HCPLY – Vietnam Plywood Manufacturer & Supplier — have integrated full-cycle environmental responsibility into every production stage, aligning with the principles of carbon reduction, renewable sourcing, and zero-waste processing.

The journey begins with the veneer itself. Okoume logs sourced from Gabon and Congo are verified under FSC® Chain of Custody certification, ensuring that every cubic meter of veneer originates from legally harvested and sustainably managed forests. These logs are transformed into thin face veneers with minimal waste thanks to modern rotary peeling and slicing systems, maximizing yield per tree while preserving forest resources. In Vietnam, the cores are crafted from plantation-grown species such as eucalyptus and acacia — fast-growing woods cultivated under reforestation programs supported by the Vietnamese government.

During production, HCPLY employs energy-efficient hot-press systems and closed-loop kiln-drying chambers that recycle exhaust heat, reducing energy consumption by up to 30%. Glue formulations have evolved toward low-VOC melamine and soy-based adhesives, eliminating the need for high-formaldehyde binders. Water used in veneer soaking and washing is filtered and recirculated, minimizing both environmental discharge and production cost.

Waste management is equally critical. Trimming and sanding residues from Okoume Face Plywood Vietnam are collected and processed into biomass fuel, providing renewable energy for factory boilers. Veneer offcuts are repurposed for packaging panels or used in core repairs, effectively achieving near-zero solid waste output. Even the plastic wraps for export packaging are biodegradable or recyclable, reinforcing Vietnam’s commitment to sustainable export operations.

The social impact of these practices is substantial. Factories in Bac Giang, Phu Tho, and Binh Dinh provinces employ local communities under safe and equitable working conditions. Training programs emphasize occupational safety, chemical handling awareness, and skill upgrading — ensuring that sustainability extends beyond environmental protection to include human welfare and skill development.

In global trade terms, these eco-driven practices give Okoume Face Plywood Vietnam a competitive edge. Importers in France, Italy, and Canada increasingly prioritize suppliers with verifiable sustainability credentials. Vietnamese producers not only meet but often exceed these expectations, providing buyers with FSC®, CARB P2, and ISO 14001-certified panels that reflect both environmental ethics and engineering excellence.

Ultimately, sustainability is no longer a marketing claim — it’s an integral part of the identity of Okoume Face Plywood Vietnam. By merging responsible forestry, efficient manufacturing, and community development, Vietnam is positioning itself as the world’s most progressive source for environmentally friendly, export-grade plywood in 2025 and beyond.

Carbon Footprint & Emission Impact Summary

Each cubic meter of Okoume Face Plywood Vietnam produced by HCPLY emits less than 160 kg CO₂e, significantly lower than the global plywood average of 240 kg CO₂e. The use of biomass-fueled boilers and heat-recovery kilns reduces carbon emissions by approximately 35%, reinforcing Vietnam’s leadership in sustainable plywood manufacturing.

🪵 9. Applications and Market Segments for Okoume Face Plywood Vietnam

The versatility of Okoume Face Plywood Vietnam is one of the main reasons behind its sustained global demand. In 2025, the product has evolved far beyond a generic panel — it now serves as a premium base material across diverse industries, from high-end furniture to marine construction and architectural design. The key lies in its perfect combination of lightweight structure, natural elegance, and export-grade durability that meets both functional and aesthetic expectations.

Furniture and Interior Manufacturing

The largest consumer of Okoume Face Plywood Vietnam remains the furniture and interior design industry. European and Middle Eastern manufacturers favor it for wardrobes, cabinets, kitchen panels, and wall décor, where a refined yet natural wood tone is desired. The smooth, pinkish Okoume surface allows for direct finishing, veneer overlaying, or lamination without the need for heavy surface treatment. Its calibrated thickness ensures compatibility with CNC cutting and modular assembly systems, reducing waste and maximizing yield per sheet.

Door Skin and Decorative Panels

Thanks to its light density and balanced fiber pattern, Okoume plywood is widely used for door skins and decorative wall panels. The even color tone and repair-free veneer make it suitable for hotel interiors, apartments, and retail spaces where aesthetics play a critical role. When bonded with phenolic or melamine resin, Okoume Face Plywood Vietnam achieves long-lasting dimensional stability, even under fluctuating humidity — a major advantage for export to tropical and desert climates.

Marine and Outdoor Applications

Okoume’s natural resistance to moisture, when paired with WBP (Water Boil Proof) adhesive, makes this plywood ideal for marine and exterior use. Builders employ it in yacht interiors, decking substrates, and boat cabinetry, particularly for clients seeking a lightweight yet stable material that complies with BS1088 marine plywood standards. Vietnamese exporters often customize marine-grade Okoume plywood with anti-fungal treatments and calibrated sanding to achieve mirror-flat surfaces suitable for epoxy coating.

Packaging and Industrial Uses

While premium markets dominate, Okoume Face Plywood Vietnam also finds utility in industrial packaging and lightweight crates, especially for airfreight applications where weight reduction translates directly into cost savings. The panels’ low density and strong bonding ensure they can withstand compression and vibration during transport without cracking or delamination.

Architectural and High-End Design

Architects increasingly specify Okoume Face Plywood Vietnam for interior cladding, acoustic panels, and ceiling systems. Its consistent texture, warm tone, and compatibility with transparent coatings allow for minimalist design concepts that showcase natural wood aesthetics. When combined with sustainability certifications such as FSC® and E0 emissions, it becomes a preferred material in LEED and BREEAM-certified green buildings.

Market Expansion Outlook

As sustainability regulations tighten globally, the demand for ethically sourced, high-precision plywood continues to grow. HCPLY and other Vietnamese manufacturers are strategically diversifying applications — from pre-finished panels to customized plywood components for modular construction and prefabricated housing. These innovations will continue to expand the reach of Okoume Face Plywood Vietnam across both traditional and emerging markets.

In essence, every application — whether in fine furniture or advanced construction — highlights Vietnam’s manufacturing excellence and strategic export positioning. By combining artistry, performance, and eco-conscious production, Okoume Face Plywood Vietnam is redefining what the world expects from tropical hardwood-based engineered panels.

🌏 Interested in premium export-grade Okoume Face Plywood Vietnam?

HCPLY offers full-container (FCL) and mixed-load (LCL) shipments with CE, FSC®, and CARB P2 certification.

📧 [email protected] | 📱 WhatsApp +84-338616333 (David)

Connect directly with our export team for detailed quotations and factory videos.

🪵 10. Future Innovations and Technological Advancements in Okoume Face Plywood Vietnam

The evolution of Okoume Face Plywood Vietnam is not slowing down — it’s accelerating through innovation, automation, and digital transformation. As global buyers demand higher precision, cleaner finishes, and traceable production, Vietnamese plywood manufacturers are embracing Industry 4.0 technologies to redefine efficiency and export competitiveness in 2025 and beyond.

Smart Manufacturing and Process Automation

Modern factories like HCPLY – Vietnam Plywood Manufacturer & Supplier are integrating CNC-based veneer scanners, AI defect detection systems, and automated lay-up lines to achieve uniform quality. These systems can identify color variations, grain mismatches, or micro-defects in Okoume veneers before pressing, reducing waste by up to 12%. Hot-pressing cycles are now digitally controlled to maintain exact pressure and temperature curves, ensuring consistent bonding strength in every batch.

Furthermore, moisture sensors embedded in kiln-drying chambers continuously monitor humidity levels, feeding real-time data into cloud systems that automatically adjust drying times. This digital approach minimizes the risk of over-drying or under-drying — two major causes of surface cracking and warping in Okoume plywood panels.

Surface Innovation and Finishing Technology

A growing trend in 2025 is pre-finished Okoume plywood — panels that leave the factory ready for direct use. Vietnamese exporters are experimenting with UV-curable coatings, matte polyurethane finishes, and anti-fingerprint laminates applied directly to Okoume Face Plywood. These innovations reduce downstream processing costs for international buyers and improve scratch resistance, making the panels ideal for modular furniture or decorative wall systems.

Another development is micro-sanding calibration, where sanding machines use laser alignment to achieve near-perfect surface flatness within ±0.1 mm. This precision makes Okoume plywood suitable for high-gloss laminations or precision veneering required in European cabinetry.

Digital Traceability and Blockchain Integration

As sustainability and transparency become global trade requirements, Vietnam’s plywood industry is adopting digital traceability solutions. Each pallet of Okoume Face Plywood Vietnam can now carry a QR-based blockchain ID that stores production data — including veneer source, glue formulation, hot-press temperature, and inspection results. Buyers in Europe or North America can scan and verify the origin, emission compliance, and batch certification instantly, reinforcing confidence in Vietnamese supply chains.

This blockchain-backed transparency is not just a compliance measure; it’s a branding tool. It positions Vietnamese plywood exporters as trust-based manufacturers, capable of meeting the rigorous documentation demands of EU Deforestation Regulation (EUDR) and Lacey Act audits.

Material Engineering and Sustainable Chemistry

Research centers in Vietnam are also pioneering low-formaldehyde and bio-based resin systems, replacing traditional melamine or phenolic adhesives with lignin-derived alternatives. These eco-binders significantly lower volatile organic compounds (VOCs), contributing to healthier indoor air quality. Similarly, hybrid cores combining eucalyptus, poplar, and plantation acacia are being engineered to optimize strength-to-weight ratios while maintaining renewable sourcing.

Vision for 2030 — Smart, Sustainable, and Scalable

By 2030, Okoume Face Plywood Vietnam is projected to evolve into a digitally managed, fully traceable, and carbon-neutral export product. Factories will rely on AI-driven predictive maintenance, solar-powered energy grids, and advanced robotic assembly lines capable of 24/7 precision operation. The synergy of automation and sustainability will not only cut production costs but also reinforce Vietnam’s identity as a global center of engineered wood innovation.

In essence, the future of Okoume plywood is not merely about manufacturing panels — it’s about crafting a new era of intelligent, transparent, and environmentally responsible wood products. Vietnam’s blend of craftsmanship and technology will ensure that Okoume Face Plywood Vietnam continues to lead the world as the benchmark for quality, sustainability, and forward-thinking design.

🌟 Conclusion

As 2025 unfolds, Okoume Face Plywood Vietnam represents not just a product — but a symbol of Vietnam’s craftsmanship, compliance, and innovation. With export-grade precision, eco-friendly adhesives, and verified traceability, it continues to redefine global standards in plywood manufacturing.

Whether you are a furniture maker, importer, or project contractor, partnering with HCPLY – Vietnam Plywood Manufacturer & Supplier ensures reliability, consistency, and value. Discover the next generation of plywood excellence — proudly made in Vietnam.