Table of contents

Is Full Birch Plywood Possible Outside Russia & China? Vietnam Explained | HCPLY – Vietnam Plywood

For decades, full birch plywood meant one thing for European buyers: Russia.

Birch face.

Birch core.

Heavy panels.

Premium pricing.

Stable supply.

Today, that reality no longer exists.

Sanctions, trade restrictions, logistics disruption, and raw material shortages have fundamentally changed global plywood sourcing. European buyers are now asking a question that would have sounded impossible just a few years ago:

Is full birch plywood possible outside Russia & China?

As a Vietnam plywood manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood answers this question from the factory floor — not from theory, not from trading assumptions, but from real production capability, material science, and export experience to EU markets.

The answer is not emotional.

It is technical.

And it requires buyers to separate myth from manufacturing reality.

This article explains clearly:

- What “full birch plywood” truly means

- Why it has become nearly impossible outside Russia

- What Vietnam can and cannot realistically deliver

- And why European buyers increasingly accept smarter, factory-controlled alternatives

This is not a downgrade.

It is the evolution of professional plywood sourcing.

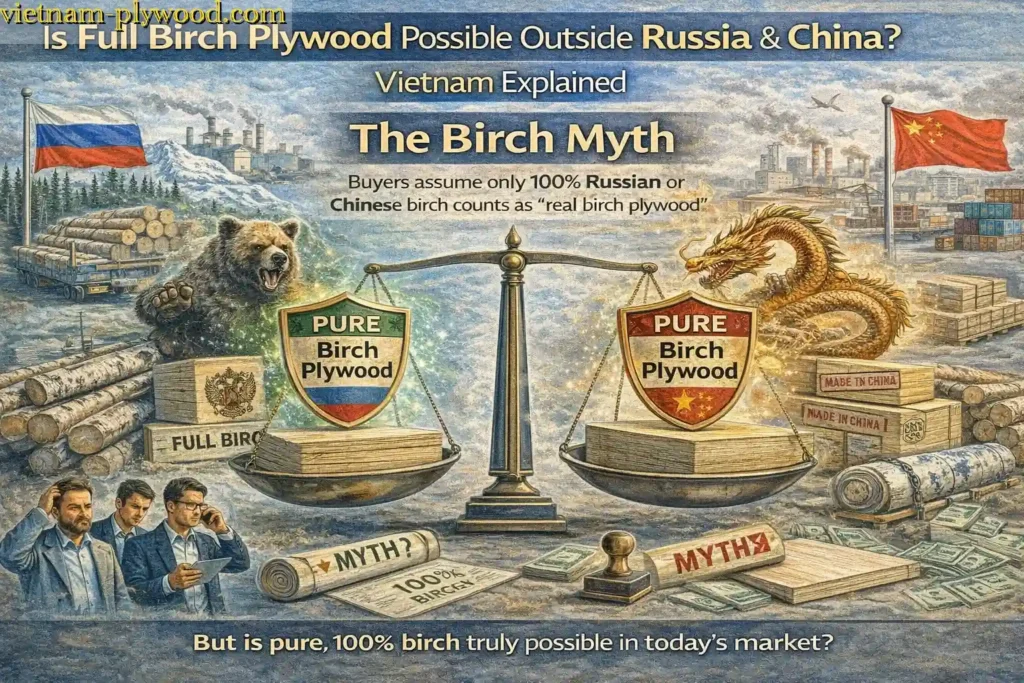

🔹 1️⃣ The Birch Myth

For decades, full birch plywood was treated as a non-negotiable standard in Europe.

If it was not Russian, it was not “real birch”.

If it was not heavy, it was not “strong”.

If it was not expensive, it was not “premium”.

This belief shaped purchasing habits for years — but it was never based on manufacturing logic. It was based on supply monopoly.

From a factory perspective, HCPLY – Vietnam Plywood, as a large-scale plywood manufacturer, supplier, and exporter, sees this clearly: the “birch myth” was created by geography, not by universal technical necessity.

Birch is a slow-growing species, concentrated in cold climates. Russia controlled both forest volume and industrial plywood capacity, which allowed one narrative to dominate the market:

- Birch face equals birch core

- Birch core equals performance

- Performance equals no alternative

That narrative ignored production reality.

In real plywood manufacturing, performance is never defined by a single species name. It is defined by:

- Veneer structure

- Core engineering

- Glue system

- Pressing cycle

- Moisture control

- Factory consistency at scale

European buyers did not buy “full birch plywood” because it was technically the only solution.

They bought it because no large alternative manufacturing system existed — until global supply chains broke.

Today, sanctions, logistics risk, and cost volatility have exposed the myth. Buyers are no longer asking where birch comes from. They are asking how plywood actually performs, and whether the structure is engineered or assumed.

As a Vietnam plywood manufacturer exporting at scale, HCPLY – Vietnam Plywood approaches birch plywood not as a legend, but as a material system — measurable, adjustable, and optimizable for modern EU requirements.

🔹 2️⃣ Why “Full Birch” Became Impossible

For many European buyers, the disappearance of full birch plywood feels sudden. In reality, it has been a slow structural collapse — hidden for years by habit, contracts, and legacy supply chains.

From a manufacturer’s perspective, not a trading narrative, the reason is simple:

👉 the raw material system that made full birch plywood possible no longer exists outside Russia and partially China.

🌲 Birch Is Not a Global Wood Species

Birch is a slow-growing hardwood, naturally concentrated in cold northern regions. Unlike poplar, eucalyptus, or acacia, it cannot be replanted and harvested on short cycles.

Only two regions historically supported true full birch plywood at scale:

- 🇷🇺 Russia – dominant forest volume + integrated plywood factories

- 🇨🇳 Northern China – partial access + mixed industrial control

Once those systems fractured, full birch plywood production collapsed globally.

❌ What Changed — And Why It’s Irreversible

From the factory floor of HCPLY – Vietnam Plywood, exporting to EU markets every month, the breakpoints are clear:

- 🚫 Sanctions & payment barriers eliminated Russian supply

- 🚫 Logistics instability destroyed cost predictability

- 🚫 Birch log export restrictions tightened raw material access

- 🚫 Environmental pressure reduced legal harvesting quotas

- 🚫 Rising energy & labor costs killed heavy-panel economics

Even where birch veneer still exists, birch core volume does not.

🏭 Manufacturing Reality (Not Marketing)

To produce true full birch plywood, a factory needs:

- Continuous supply of birch logs (not veneers)

- Uniform density across all plies

- Long press cycles and heavy glue consumption

- Weight tolerance accepted by logistics and buyers

Today, no country outside Russia can sustain this at industrial export scale — including Vietnam.

And Vietnam does not pretend otherwise.

As a Vietnam plywood manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood does not sell myths. We design what is physically, economically, and legally manufacturable for EU buyers.

⚠️ The Critical Buyer Mistake

Many buyers still ask:

“Can Vietnam make full birch plywood?”

The correct factory-level question is:

“Should full birch plywood still be the reference standard?”

Because insisting on an impossible structure creates:

- Higher rejection risk

- Inconsistent quality

- Unstable pricing

- Hidden compliance exposure

The market didn’t lose full birch plywood overnight.

👉 It outgrew it.

And professional buyers are already adapting — with engineered alternatives that deliver performance without dependence on a broken supply system.

That is where Vietnam enters the picture — realistically, transparently, and at scale.

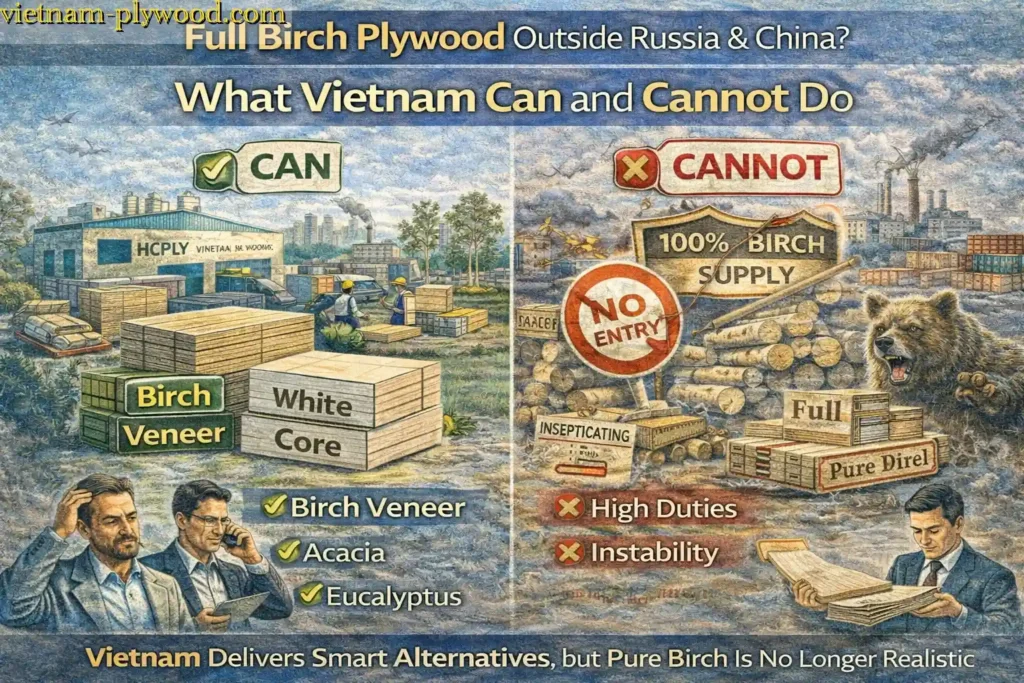

🔹 3️⃣ What Vietnam Can and Cannot Do

When European buyers ask whether full birch plywood is possible outside Russia & China, the most professional answer is not marketing — it is manufacturing truth.

As a Vietnam plywood manufacturer, supplier, and exporter at industrial scale, HCPLY – Vietnam Plywood draws a clear line between what Vietnam can realistically deliver and what no factory should promise.

✅ What Vietnam CAN Do — At Scale, Consistently

Vietnam does not attempt to copy a broken Russian model. Instead, Vietnam builds engineered plywood systems optimized for today’s EU market realities.

From the factory floor of HCPLY – Vietnam Plywood, Vietnam can deliver:

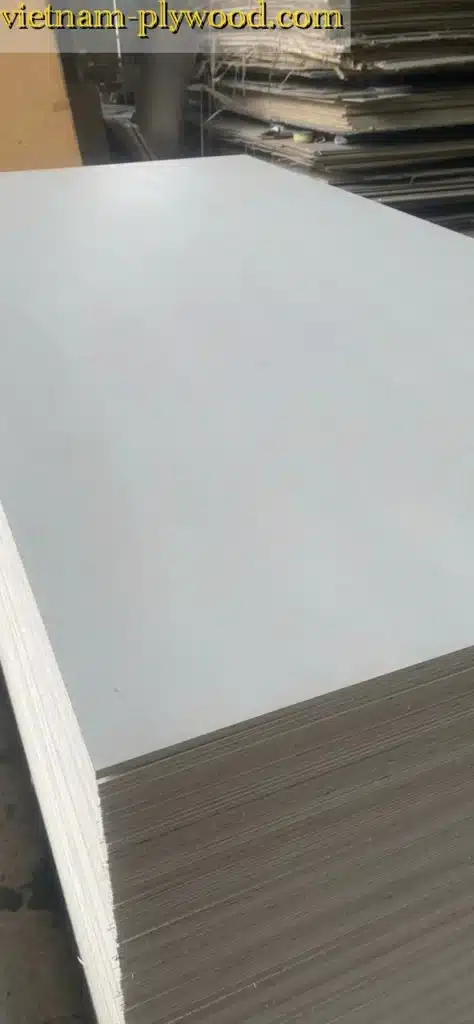

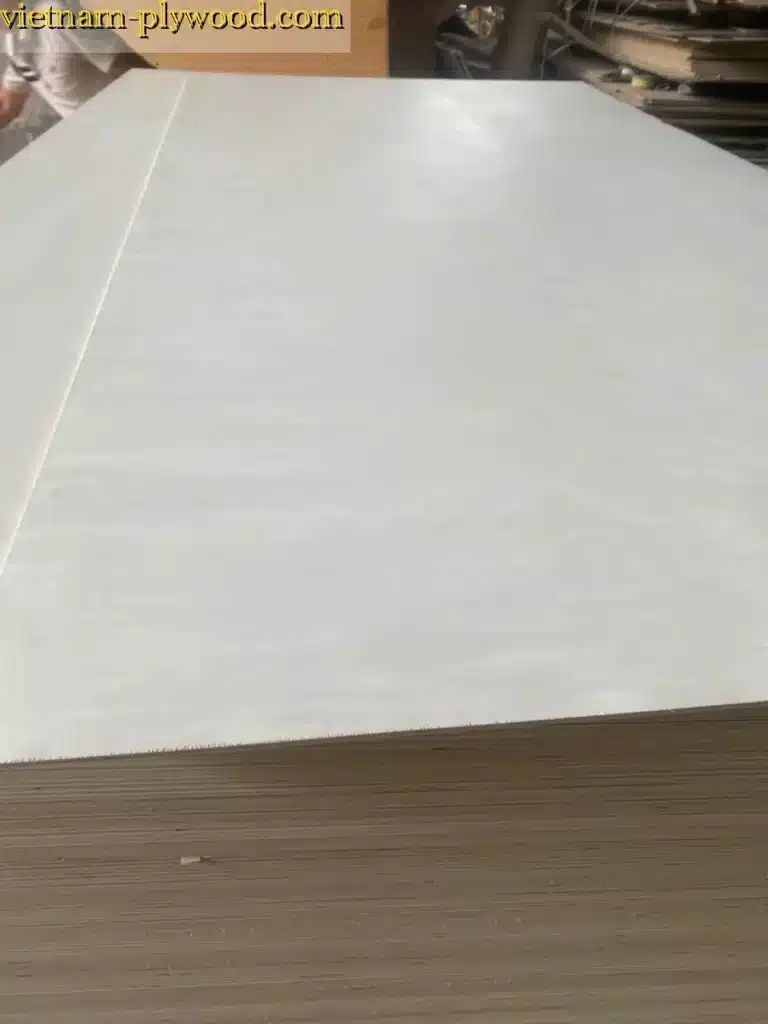

- ✔️ High-quality birch face veneers

Imported, selected, and controlled for grain, thickness, and moisture - ✔️ Full white engineered core

Using poplar / styrax / selected hardwood layers with uniform density - ✔️ Precision veneer layup

Balanced structure, controlled ply count, and stress symmetry - ✔️ EU-compliant glue systems

E0 / E1 / CARB P2 phenolic & melamine systems - ✔️ Stable mass production

Large volumes, repeatable quality, predictable lead times - ✔️ Export-ready compliance

FSC, EUDR-ready documentation, CE-oriented production control

This is not imitation birch plywood.

It is engineered birch-faced plywood, designed to perform — not to satisfy outdated definitions.

❌ What Vietnam CANNOT Do — And Will Not Pretend

Equally important, Vietnam cannot and should not do the following:

- ❌ Source continuous volumes of birch logs for full birch core

- ❌ Produce ultra-heavy birch-core panels without logistics penalties

- ❌ Replicate Russian forest economics under EU regulations

- ❌ Sustain unstable raw material dependency for long-term contracts

Any supplier claiming otherwise is selling risk, not plywood.

As a responsible Vietnam plywood manufacturer and exporter, HCPLY – Vietnam Plywood does not label limitations as disadvantages — we treat them as design constraints.

🏭 Factory-Level Comparison (Reality Check)

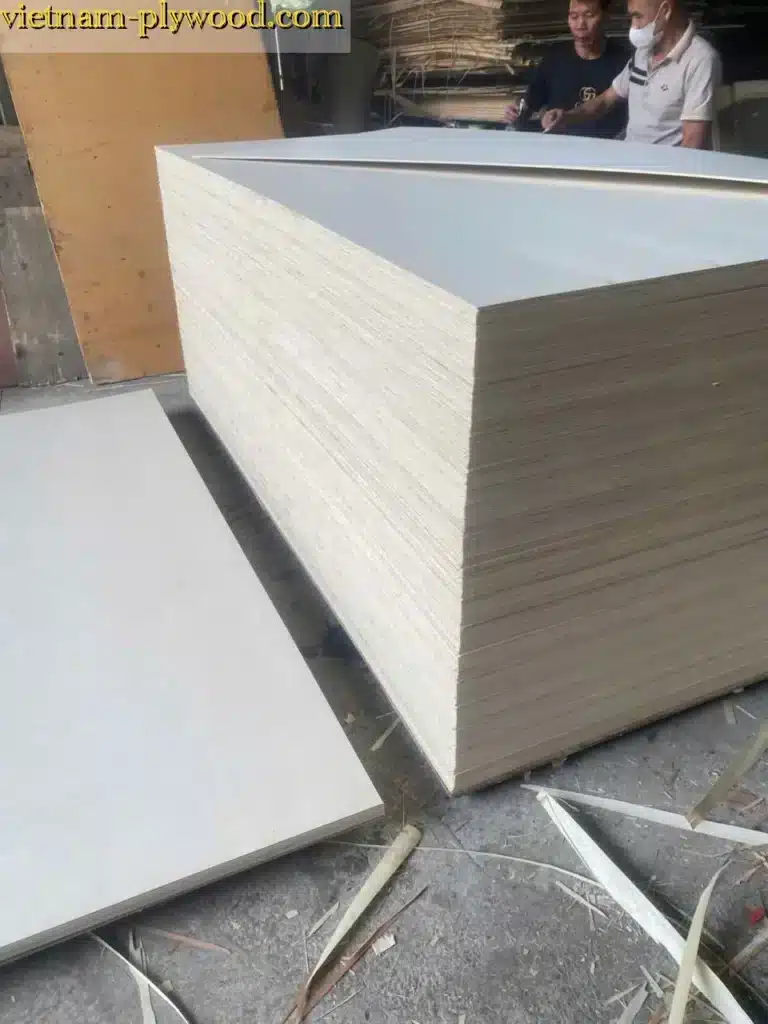

| Factor | Old “Full Birch” Model | Vietnam Engineered Model |

|---|---|---|

| Raw material | Birch logs only | Birch face + white core |

| Supply stability | Broken / restricted | Stable & scalable |

| Weight | Very heavy | Optimized |

| Cost control | Unpredictable | Competitive |

| EU compliance | High risk | Controlled |

| Export consistency | Declining | Strong |

🔧 Manufacturing Philosophy at HCPLY

At HCPLY – Vietnam Plywood, we do not ask:

“Can we recreate the past?”

We ask:

👉 “Can we engineer a better-performing, lower-risk solution for European buyers today?”

That philosophy is why Vietnam has become the preferred alternative manufacturing base — not because it replaces birch, but because it redefines how birch plywood should be built in a post-Russia market.

Vietnam does not sell myths.

Vietnam sells manufacturing logic.

And that logic starts with knowing exactly what is possible — and what is not.

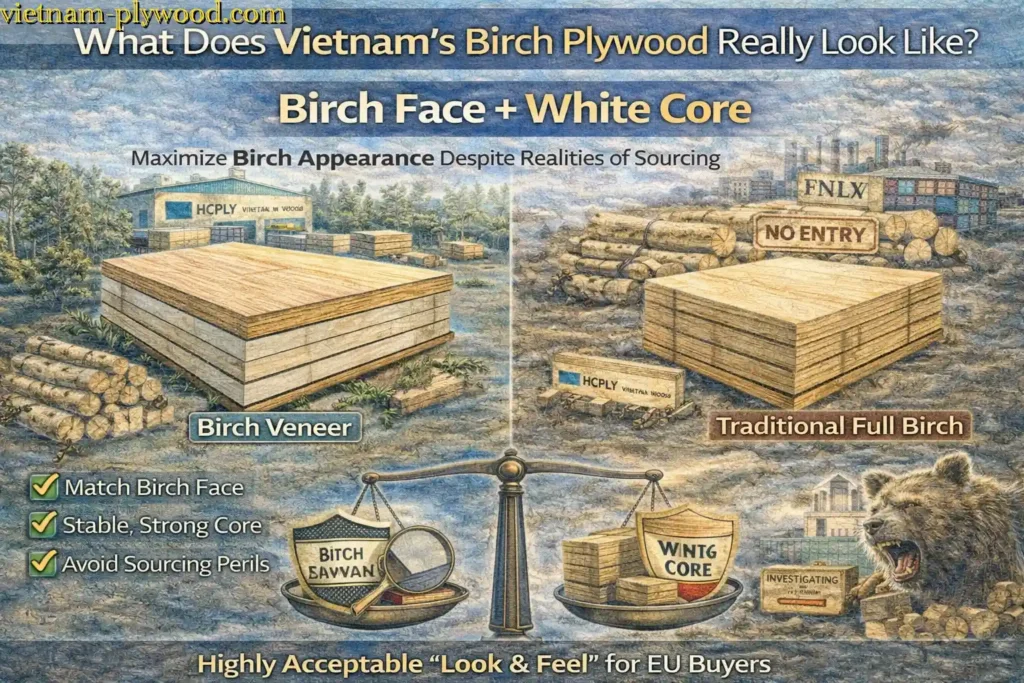

When European buyers ask “is full birch plywood possible outside Russia & China?”, many suppliers still answer emotionally instead of technically.

As a Vietnam plywood manufacturer, HCPLY – Vietnam Plywood addresses this question based on actual birch plywood Vietnam production capability, not assumptions.

First, one fact must be clarified clearly:

Full birch plywood (birch face + birch core + birch crossbands) is not realistically possible in Vietnam today.

This is not a limitation of technology.

It is a limitation of raw material geography and sustainable supply.

Vietnam does not grow industrial birch forests. Therefore, any claim of “full birch plywood Vietnam” is either:

- A misunderstanding of structure, or

- A marketing shortcut that hides mixed-core reality.

So what does birch plywood Vietnam actually mean when produced by a professional Vietnam plywood manufacturer?

🏭 Birch-Faced Engineered Plywood (The Real Answer)

Modern birch plywood Vietnam is engineered plywood, not imitation plywood.

At HCPLY – Vietnam Plywood, birch plywood is designed as a performance system, consisting of:

- Genuine birch face veneers (imported, graded, and controlled)

- Engineered white core (poplar / styrax / eucalyptus, depending on application)

- Cross-banded structure for strength balance

- CARB P2 / E0 glue systems suitable for EU interior standards

This structure delivers functional equivalence to traditional full birch plywood in:

- Interior furniture

- Cabinet carcasses

- Drawer systems

- Wall panels

- Commercial interiors

And it does so without depending on an impossible birch core supply chain.

⚖️ Why This Structure Works (And Why Buyers Accept It)

From a Vietnam plywood manufacturer perspective, performance comes from engineering, not species obsession.

Compared to traditional full birch plywood, engineered birch plywood Vietnam offers:

- ✅ More stable weight control

- ✅ Better container loading efficiency

- ✅ Lower moisture movement risk

- ✅ Predictable pricing across contracts

- ✅ Easier EUDR & legality documentation

- ✅ Consistent quality across batches

This is why European buyers asking “is full birch plywood possible outside Russia & China?” are increasingly reframing the question to:

“Can birch plywood Vietnam deliver the same performance with lower supply risk?”

For most interior and commercial uses, the answer is yes.

🚫 What Birch Plywood Vietnam Is NOT

To avoid confusion, a professional Vietnam plywood manufacturer must also be honest about limits.

Birch plywood Vietnam is not:

- Structural plywood for heavy load-bearing formwork

- A 1:1 replacement for 100% Russian birch in extreme mechanical tests

- A cosmetic product for buyers who only trade on weight perception

And HCPLY – Vietnam Plywood does not position it as such.

🎯 The Buyer’s Real Decision Point

The real question is no longer “is full birch plywood possible?”

The real question is:

Is full birch plywood still necessary for your application?

For many European importers, insisting on “full birch only” now creates:

- Supply instability

- Higher rejection risk

- Price volatility

- Compliance exposure

Meanwhile, engineered birch plywood Vietnam, produced by an experienced Vietnam plywood manufacturer, delivers:

- Control

- Transparency

- Performance consistency

- Long-term sourcing security

This is why birch plywood Vietnam has become a professional alternative — not a compromise.

And this shift is already happening across EU interiors, furniture manufacturing, and panel distribution networks.

4️⃣ What “Birch Plywood from Vietnam” Really Means Today (Factory Reality, Not Marketing)

When European buyers ask “is full birch plywood possible outside Russia & China?”, many suppliers still answer emotionally instead of technically.

As a Vietnam plywood manufacturer, HCPLY – Vietnam Plywood addresses this question based on actual birch plywood Vietnam production capability, not assumptions.

First, one fact must be clarified clearly:

Full birch plywood (birch face + birch core + birch crossbands) is not realistically possible in Vietnam today.

This is not a limitation of technology.

It is a limitation of raw material geography and sustainable supply.

Vietnam does not grow industrial birch forests. Therefore, any claim of “full birch plywood Vietnam” is either:

- A misunderstanding of structure, or

- A marketing shortcut that hides mixed-core reality.

So what does birch plywood Vietnam actually mean when produced by a professional Vietnam plywood manufacturer?

🏭 Birch-Faced Engineered Plywood (The Real Answer)

Modern birch plywood Vietnam is engineered plywood, not imitation plywood.

At HCPLY – Vietnam Plywood, birch plywood is designed as a performance system, consisting of:

- Genuine birch face veneers (imported, graded, and controlled)

- Engineered white core (poplar / styrax / eucalyptus, depending on application)

- Cross-banded structure for strength balance

- CARB P2 / E0 glue systems suitable for EU interior standards

This structure delivers functional equivalence to traditional full birch plywood in:

- Interior furniture

- Cabinet carcasses

- Drawer systems

- Wall panels

- Commercial interiors

And it does so without depending on an impossible birch core supply chain.

⚖️ Why This Structure Works (And Why Buyers Accept It)

From a Vietnam plywood manufacturer perspective, performance comes from engineering, not species obsession.

Compared to traditional full birch plywood, engineered birch plywood Vietnam offers:

- ✅ More stable weight control

- ✅ Better container loading efficiency

- ✅ Lower moisture movement risk

- ✅ Predictable pricing across contracts

- ✅ Easier EUDR & legality documentation

- ✅ Consistent quality across batches

This is why European buyers asking “is full birch plywood possible outside Russia & China?” are increasingly reframing the question to:

“Can birch plywood Vietnam deliver the same performance with lower supply risk?”

For most interior and commercial uses, the answer is yes.

🚫 What Birch Plywood Vietnam Is NOT

To avoid confusion, a professional Vietnam plywood manufacturer must also be honest about limits.

Birch plywood Vietnam is not:

- Structural plywood for heavy load-bearing formwork

- A 1:1 replacement for 100% Russian birch in extreme mechanical tests

- A cosmetic product for buyers who only trade on weight perception

And HCPLY – Vietnam Plywood does not position it as such.

🎯 The Buyer’s Real Decision Point

The real question is no longer “is full birch plywood possible?”

The real question is:

Is full birch plywood still necessary for your application?

For many European importers, insisting on “full birch only” now creates:

- Supply instability

- Higher rejection risk

- Price volatility

- Compliance exposure

Meanwhile, engineered birch plywood Vietnam, produced by an experienced Vietnam plywood manufacturer, delivers:

- Control

- Transparency

- Performance consistency

- Long-term sourcing security

This is why birch plywood Vietnam has become a professional alternative — not a compromise.

And this shift is already happening across EU interiors, furniture manufacturing, and panel distribution networks.

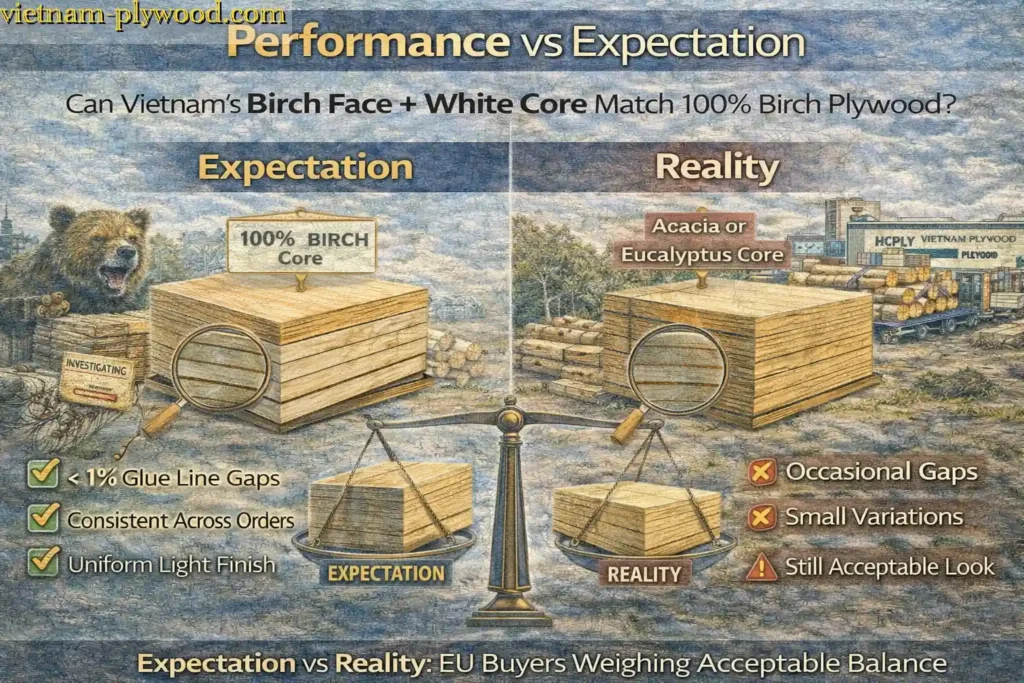

🔹 5️⃣ Performance vs Expectation: When “Full Birch” Is No Longer the Benchmark

For years, European buyers measured plywood quality against one fixed expectation: full birch plywood.

Heavy panels, dense core, and a belief that more weight automatically meant more performance.

Today, that expectation no longer matches manufacturing reality.

As a Vietnam plywood manufacturer, supplier, and exporter at large industrial scale, HCPLY – Vietnam Plywood sees a clear gap between what buyers expect from full birch plywood and what their applications actually require.

⚖️ The Old Expectation: “Full Birch Equals Maximum Performance”

The traditional expectation behind full birch plywood possible was based on three assumptions:

- 🟤 Higher density = higher strength

- 🟤 Birch core = universal solution

- 🟤 Heavier panel = better quality

Those assumptions were shaped by a time when Russian supply was stable and alternatives did not exist.

They are no longer technically accurate.

🔬 Real Performance Comes From Structure, Not Myth

From the factory floor of HCPLY – Vietnam Plywood, plywood performance is evaluated by measurable criteria — not by legacy labels.

Key performance drivers include:

- ✔️ Face veneer quality (grain, thickness, bonding)

- ✔️ Core balance and density consistency

- ✔️ Cross-banding accuracy

- ✔️ Glue penetration and curing cycle

- ✔️ Moisture stability under EU climate conditions

- ✔️ Rejection rate across large production batches

None of these depend exclusively on a full birch core.

🧪 Engineered Birch-Faced Plywood vs Full Birch Plywood

In controlled factory testing and real EU usage, engineered birch plywood Vietnam delivers equivalent or superior results for most interior and furniture applications.

| Performance Factor | Traditional Full Birch | Birch-Faced Engineered (Vietnam) |

|---|---|---|

| Bending stability | High | High / more balanced |

| Screw holding | High | High (optimized core zones) |

| Surface finish | Excellent | Excellent |

| Moisture movement | Higher risk | More stable |

| Weight control | Very heavy | Optimized |

| Batch consistency | Declining | Controlled |

This is why the question “is full birch plywood possible?” is increasingly replaced by:

👉 Is full birch plywood still necessary to achieve the performance we need?

🏭 Factory Reality at Scale

At export scale, performance is not judged by a single test panel — it is judged by thousands of sheets per month.

As a leading Vietnam plywood manufacturer, HCPLY – Vietnam Plywood prioritizes:

- 📦 Consistent performance across containers

- 📦 Low rejection rates at customer factories

- 📦 Predictable machining behavior

- 📦 Stable long-term supply contracts

Full birch plywood, where still available, often fails these criteria due to raw material inconsistency and weight-related logistics stress.

🎯 Where Buyer Expectations Are Shifting

European buyers who once insisted on full birch plywood possible are now redefining success as:

- ✅ Functional equivalence, not species purity

- ✅ Performance under real use, not lab mythology

- ✅ Stability over time, not one-off shipments

- ✅ Factory-controlled structure, not trader promises

This shift explains why birch plywood Vietnam, produced by an experienced Vietnam plywood manufacturer, is increasingly specified by engineers, not just purchasers.

🚫 When Expectations Become Risk

Clinging to outdated expectations creates real problems:

- ❌ Overweight panels increase freight cost

- ❌ Unstable supply increases production delays

- ❌ Inconsistent quality increases rejection risk

- ❌ Compliance documentation becomes harder to control

From a manufacturer’s perspective, these risks outweigh any symbolic value of “full birch”.

✅ Performance That Matches Today’s Reality

At HCPLY – Vietnam Plywood, performance is engineered to match today’s EU furniture, interior, and commercial requirements — not yesterday’s myths.

This is why engineered birch plywood Vietnam is not a downgrade.

It is the professional evolution of what full birch plywood was supposed to deliver — without depending on a supply chain that no longer exists.

🔹 6️⃣ Weight & Logistics Reality: When Birch Becomes a Freight Problem

For decades, European buyers accepted one uncomfortable truth without questioning it: full birch plywood is heavy.

What was once considered a sign of quality has now become one of the biggest hidden costs in global plywood sourcing.

From the perspective of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, weight is not an abstract concept — it is a logistics equation that directly affects margins, delivery reliability, and buyer competitiveness.

🚢 The Forgotten Cost of “Heavy Quality”

Traditional full birch plywood typically reaches densities of:

- ⚖️ 650–720 kg/m³

- ⚖️ Extremely high container weight per CBM

- ⚖️ Limited CBM per 40HQ due to weight caps

In today’s freight environment, this creates immediate problems:

- ❌ Containers hit weight limits before volume limits

- ❌ Fewer CBMs per shipment

- ❌ Higher freight cost per square meter

- ❌ Increased port and inland handling fees

What buyers once saw as “solid quality” is now logistics inefficiency.

📦 Real 40HQ Container Math (Factory Reality)

From actual export data at HCPLY – Vietnam Plywood:

| Plywood Type | Avg Density | Typical Load / 40HQ |

|---|---|---|

| Full Birch Plywood | 680–720 kg/m³ | ~42–44 CBM |

| Birch-Faced Engineered (Vietnam) | 520–560 kg/m³ | ~52–55 CBM |

This difference is not theoretical.

👉 It directly impacts landed cost, stock planning, and price competitiveness in EU markets.

💸 Weight vs Landed Cost (The Hidden Trap)

Many buyers still compare plywood by FOB price only.

As a Vietnam plywood manufacturer exporting at scale, HCPLY – Vietnam Plywood sees this mistake repeatedly:

- 🧾 Full birch plywood FOB looks “acceptable”

- 🚢 Freight cost quietly increases

- 📉 Cost per usable m² rises

- 📦 Inventory turns slow down

In contrast, birch plywood Vietnam with engineered white core delivers:

- ✔️ Higher CBM per container

- ✔️ Lower freight cost per m²

- ✔️ More predictable landed pricing

- ✔️ Better warehouse efficiency

⚖️ Structural Performance Does NOT Scale with Weight

A critical misunderstanding among buyers is assuming that more weight = more performance.

From factory testing and EU customer feedback:

- Structural performance plateaus beyond a certain density

- Excess weight adds stress to joints, fixtures, and transport

- Machining becomes less forgiving

- Handling costs increase across the supply chain

Performance is about structure, not mass.

🏭 Why Vietnam’s Engineered Model Wins Logistics

As a professional Vietnam plywood manufacturer, HCPLY – Vietnam Plywood designs birch plywood structures to balance:

- 🌍 EU logistics constraints

- 🧱 Mechanical performance

- 📦 Container efficiency

- 💶 Total landed cost

This is why birch plywood Vietnam is increasingly specified not by purchasing teams — but by engineers, logistics managers, and production planners.

🚫 When Full Birch Becomes a Liability

Insisting on full birch plywood today often results in:

- ❌ Overweight containers

- ❌ Reduced shipment flexibility

- ❌ Higher carbon footprint per unit

- ❌ Margin erosion hidden inside freight invoices

These are risks, not advantages.

✅ Logistics-Aligned Performance Is the New Standard

At HCPLY – Vietnam Plywood, plywood is engineered to move efficiently — not just to look traditional on a spec sheet.

For modern European buyers, the real question is no longer:

“Is this plywood heavy enough?”

The real question is:

👉 “Does this plywood deliver performance without punishing logistics?”

In today’s market, the answer increasingly comes from Vietnam plywood manufacturers who understand that weight control is not compromise — it is professional supply chain design.

🔹 7️⃣ Cost Advantage Explained: Why “Not Full Birch” Wins Economically

For many European buyers, the discussion around full birch plywood possible often stops at material purity.

In reality, the decisive factor today is cost structure, not species label.

From the factory-level view of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, the cost advantage of engineered birch plywood Vietnam is structural, transparent, and repeatable — not temporary.

💶 The Old Cost Model: Full Birch = Compounding Expense

Traditional full birch plywood carries multiple cost layers that buyers rarely see in one picture:

- 🪵 Raw material premium – birch logs are scarce and politically sensitive

- ⚡ Energy-intensive pressing – higher density, longer press cycles

- 🧪 Higher glue consumption – dense core requires more adhesive

- 🚢 Freight penalty – overweight panels reduce CBM per container

- 📉 Risk buffer pricing – suppliers price in instability

Each layer compounds the final landed cost.

🧾 FOB Is Not the Real Cost

As an export-oriented Vietnam plywood manufacturer, HCPLY – Vietnam Plywood works with buyers who have learned this the hard way:

| Cost Layer | Full Birch Plywood | Birch-Faced Engineered (Vietnam) |

|---|---|---|

| Raw material | Very high & volatile | Controlled & diversified |

| Production cost | High | Optimized |

| FOB price | Looks comparable | Competitive |

| Freight per m² | High | Lower |

| Rejection risk | Rising | Controlled |

| Landed cost | Unstable | Predictable |

👉 The true comparison is cost per usable square meter, not FOB per sheet.

📦 Container Efficiency = Direct Savings

Because engineered birch plywood Vietnam is lighter and structurally balanced:

- ✔️ More CBM per 40HQ

- ✔️ Lower freight cost per panel

- ✔️ Better inventory turnover

- ✔️ Reduced cash tied in transit

For importers and distributors, this difference alone often offsets any perceived “premium” of birch face veneers.

🏭 Factory-Controlled Cost Stability

At HCPLY – Vietnam Plywood, cost advantage is not created by cutting corners — it is created by control:

- 🌱 Plantation-based core sourcing

- 🔁 Repeatable production recipes

- 📊 Yield optimization across batches

- 📑 Compliance-ready documentation (no risk premium)

- 📆 Long-term supply planning, not spot buying

This allows HCPLY – Vietnam Plywood to offer competitive pricing that remains stable across contracts, even when global conditions fluctuate.

⚠️ Why “Cheapest Birch” Is the Most Expensive Choice

Buyers leaving Russia or China often fall into one trap:

chasing the cheapest “birch plywood” label.

This usually results in:

- ❌ Mixed or misdeclared cores

- ❌ Inconsistent density

- ❌ Higher rejection rates

- ❌ Hidden rework and downtime costs

From a manufacturer’s standpoint, cheap birch plywood is rarely economical.

✅ Cost Advantage That Scales With Volume

For medium to large EU buyers, the cost advantage of engineered birch plywood Vietnam becomes stronger as volume increases:

- 📦 Lower cost per container

- 📉 Lower variance across shipments

- 🤝 Easier long-term price agreements

- 🔄 Reliable repeat orders

This is why professional buyers no longer ask:

“Is full birch plywood possible?”

They ask:

“Which structure gives us the lowest total cost without sacrificing performance?”

🎯 HCPLY’s Position on Cost

As a leading Vietnam plywood manufacturer and exporter, HCPLY – Vietnam Plywood positions birch plywood not as a nostalgic product, but as a cost-engineered solution.

The result is not cheaper plywood.

It is smarter plywood — designed for today’s freight reality, compliance environment, and competitive EU market.

And that is where real cost advantage lives.

🔹 8️⃣ EU Buyer Acceptance Trend: From Resistance to Standard Practice

Only a few years ago, many European buyers reacted defensively when the idea of moving away from full birch plywood was raised.

Today, that resistance has largely disappeared — replaced by pragmatism, engineering logic, and supply-chain realism.

From the export data and long-term customer feedback of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, the acceptance trend is no longer emerging.

👉 It is already established.

🇪🇺 How EU Buyers Actually Think Today

European buyers are no longer asking:

- “Is this 100% birch core?”

- “Is it as heavy as Russian birch?”

Instead, they are asking:

- ✅ Is the performance consistent across containers?

- ✅ Is the structure stable under EU climate conditions?

- ✅ Is supply secure for 12–36 months?

- ✅ Is documentation compliant with EUDR / EUTR?

- ✅ Is the landed cost predictable?

These questions favor engineered birch plywood Vietnam, not legacy full birch plywood.

📈 Acceptance by Buyer Segment

From HCPLY – Vietnam Plywood’s export portfolio, acceptance follows a clear pattern:

- 🪑 Furniture manufacturers

Focus on machining, surface quality, and repeatability

→ Strong adoption of birch-faced white core plywood - 🏬 EU distributors & importers

Focus on stock turnover and freight efficiency

→ Preference for lighter, stable panels - 🏗️ Commercial interior contractors

Focus on compliance and delivery reliability

→ Engineered birch plywood becomes default - 🏭 OEM factories

Focus on cost control and long-term contracts

→ Engineered structure preferred over species purity

🧠 What Changed Buyer Psychology

The turning point was not marketing.

It was experience.

Buyers learned that:

- ❌ “Full birch” did not guarantee consistency

- ❌ Heavy panels did not prevent rejections

- ❌ Legacy suppliers did not ensure stability

- ❌ Species purity did not reduce risk

Meanwhile, engineered birch plywood Vietnam delivered:

- ✔️ Stable panel behavior

- ✔️ Lower freight cost

- ✔️ Fewer quality disputes

- ✔️ Easier compliance management

📊 Acceptance Curve (Factory Reality)

| Buyer Stage | Typical Reaction |

|---|---|

| First inquiry | Skeptical |

| Sample testing | Neutral |

| Trial container | Positive |

| Second order | Confident |

| Contract supply | Fully accepted |

This curve repeats consistently across EU markets.

🏭 Why Manufacturer-Origin Matters

Acceptance is fastest when buyers work directly with a Vietnam plywood manufacturer, not traders.

At HCPLY – Vietnam Plywood, acceptance accelerates because:

- Core structure is disclosed

- Performance limits are clearly defined

- Specifications are engineered, not improvised

- Quality is repeatable at volume

Transparency builds trust faster than promises.

🚫 Where Resistance Still Exists

Resistance remains mainly among:

- Buyers trading on resale myths

- Buyers selling “weight as quality”

- Buyers without technical evaluation capability

These segments are shrinking rapidly.

✅ The New EU Reference Standard

For most EU applications, the new reference standard is:

- Birch face quality

- White engineered core

- Controlled density

- Stable logistics

- Documented compliance

This standard aligns perfectly with what HCPLY – Vietnam Plywood manufactures at scale.

🎯 Conclusion of the Trend

European buyers did not abandon full birch plywood emotionally.

They moved on professionally.

And as long as global supply chains demand stability over nostalgia, birch plywood Vietnam, produced by experienced Vietnam plywood manufacturers, will continue to gain acceptance — not as an alternative, but as a modern standard.

🔹 9️⃣ HCPLY Manufacturing Approach: How Vietnam Builds Birch Plywood the Right Way

When European buyers ask whether full birch plywood possible outside Russia & China, the most important factor is not theory — it is how the plywood is actually manufactured.

At HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, our approach is not to replicate a broken model, but to engineer a solution that works at volume, with consistency, compliance, and cost control.

🏭 Manufacturer-First, Not Trader-Driven

HCPLY – Vietnam Plywood operates as a direct factory, not a trading intermediary.

This distinction defines everything:

- 🪵 Full control over face veneer selection

- 🧱 Full control over core composition

- 🧪 In-house glue formulation & pressing cycles

- 📏 Tight tolerance management across batches

- 📦 Export-focused production planning

This factory-controlled model is why HCPLY – Vietnam Plywood can deliver birch plywood Vietnam consistently — not opportunistically.

🌳 Raw Material Strategy: Honest & Sustainable

Unlike suppliers who claim “full birch” without disclosing structure, HCPLY – Vietnam Plywood defines materials transparently:

- ✔️ Genuine birch face veneers (imported, graded, moisture-controlled)

- ✔️ White engineered core (poplar / styrax / eucalyptus depending on application)

- ✔️ Plantation-based sourcing for long-term legality and EUDR readiness

We do not rely on speculative birch log supply.

We rely on repeatable material systems.

🔧 Engineered Core Philosophy

From a Vietnam plywood manufacturer perspective, the core is not filler — it is a performance component.

HCPLY – Vietnam Plywood engineers core structures to achieve:

- ⚖️ Balanced density across plies

- 📐 Symmetrical stress distribution

- 🔩 Reliable screw holding in furniture zones

- 🌡️ Reduced moisture movement

- 🚢 Optimized panel weight for logistics

This is how birch plywood Vietnam achieves functional equivalence to traditional full birch plywood in real EU applications.

🧪 Glue, Pressing & Quality Control

Performance consistency comes from process discipline:

- 🧪 E0 / E1 / CARB P2 glue systems

- 🔥 Controlled hot-press temperature & time

- 📊 Batch-level QC tracking

- 📦 Final inspection aligned with EU buyer specs

As a professional Vietnam plywood manufacturer, HCPLY – Vietnam Plywood designs production for thousands of sheets per month, not for showroom samples.

📑 Compliance Built Into Manufacturing

Compliance is not an add-on at HCPLY – Vietnam Plywood — it is embedded:

- 📄 FSC / controlled wood systems

- 📍 Traceability aligned with EUTR & EUDR frameworks

- 🧾 Export documentation consistency

- 🏷️ Honest labeling of structure and species

This reduces buyer risk and eliminates the need for “explanations after shipment”.

🔁 Repeatability Over Promises

The real test of any manufacturing approach is not the first order — it is the tenth.

HCPLY – Vietnam Plywood focuses on:

- 🔁 Repeat orders, not one-off deals

- 📆 Long-term contracts, not spot shipments

- 🤝 Partnership with EU buyers, not transactional sales

This is why buyers who initially ask “is full birch plywood possible?” eventually stop asking that question.

They start asking:

“Can this factory deliver the same quality every time?”

🎯 HCPLY’s Manufacturing Position

As a leading Vietnam plywood manufacturer and exporter, HCPLY – Vietnam Plywood does not claim to replace Russia’s past.

We offer something more valuable:

- Stability

- Transparency

- Engineering logic

- Export reliability

That is how birch plywood Vietnam is manufactured correctly today — and why professional European buyers increasingly choose factories like HCPLY – Vietnam Plywood to build their next supply chain.

🔹 🔟 When This Solution Is Ideal: Clear Use Cases for Birch Plywood Vietnam

After understanding the reality behind the question full birch plywood possible, the final and most practical issue for European buyers is simple:

👉 When is birch plywood Vietnam the right solution — and when is it not?

From the factory-level experience of HCPLY – Vietnam Plywood, a large-scale Vietnam plywood manufacturer, supplier, and exporter, the answer is very clear when evaluated by application, not emotion.

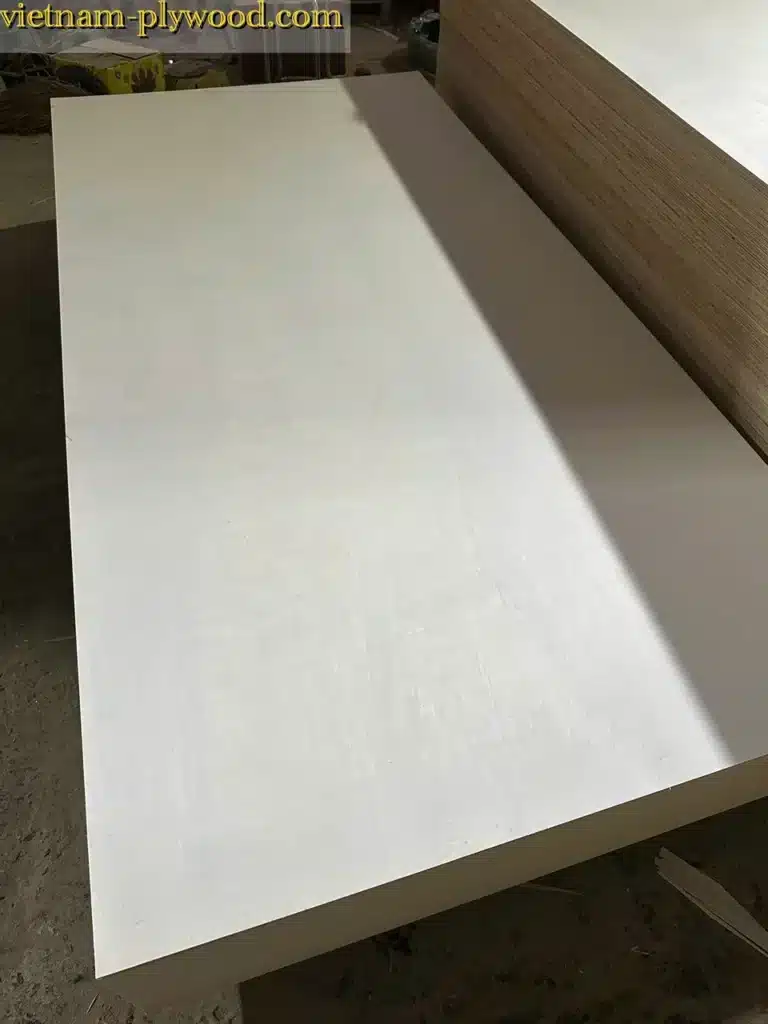

✅ Ideal Applications Where Birch Plywood Vietnam Excels

Birch-faced engineered plywood manufactured by HCPLY – Vietnam Plywood is ideal when buyers prioritize performance, stability, and supply security.

🪑 Furniture Manufacturing

- Cabinet carcasses

- Drawer systems

- Shelving units

- Table components

- Flat-pack furniture

Why it works

- Excellent surface quality from birch face

- Predictable machining behavior

- Stable screw holding

- Consistent panel thickness at volume

🏬 Commercial & Residential Interiors

- Wall panels

- Interior partitions

- Shopfitting

- Office furniture

- Hospitality interiors

Why it works

- Lighter weight reduces installation strain

- Controlled moisture movement

- Clean white core for edge finishing

- Compliance-ready for EU projects

🏭 OEM & Contract Manufacturing

- Private-label furniture

- Long-term supply programs

- Multi-container monthly orders

Why it works

- Stable pricing across contracts

- Factory-controlled repeatability

- Lower landed cost per m²

- Reduced rejection and downtime risk

⚖️ Where Full Birch Is Still Justified (Limited Cases)

As an honest Vietnam plywood manufacturer, HCPLY – Vietnam Plywood also clarifies where birch plywood Vietnam may not be the best fit:

- Heavy structural load-bearing applications

- Extreme mechanical stress environments

- Buyers trading solely on legacy “full birch” labels

- Projects where weight is mistakenly used as a quality signal

In these niche cases, full birch plywood may still be specified — but availability, cost, and risk must be clearly accepted.

📊 Decision Guide: Birch Vietnam vs Full Birch

| Decision Factor | Birch Plywood Vietnam | Traditional Full Birch |

|---|---|---|

| Supply stability | ✅ High | ❌ Uncertain |

| Landed cost | ✅ Competitive | ❌ Volatile |

| Logistics efficiency | ✅ Optimized | ❌ Heavy |

| Batch consistency | ✅ Controlled | ❌ Declining |

| EU compliance | ✅ Documented | ❌ Risky |

| Volume scalability | ✅ Strong | ❌ Limited |

🏭 Why Manufacturer Choice Determines Success

The success of birch plywood Vietnam depends less on the concept — and more on who manufactures it.

At HCPLY – Vietnam Plywood:

- Core structure is transparent

- Performance limits are clearly defined

- Quality is repeatable at industrial scale

- Export documentation is standardized

- Long-term supply is planned, not improvised

This factory-first model is why professional EU buyers transition smoothly — while others struggle.

🎯 The Final Answer to the Question

So, is full birch plywood possible outside Russia & China?

Technically: No, not sustainably.

Practically: It is no longer necessary.

For the majority of modern EU applications, birch plywood Vietnam, manufactured by a reliable Vietnam plywood manufacturer like HCPLY – Vietnam Plywood, delivers:

- The performance buyers actually use

- The stability supply chains now demand

- The cost structure markets require

- The compliance Europe enforces

This is not a compromise.

It is the next-generation standard for birch plywood sourcing — and it is already being adopted across Europe.

And that is where the future of birch plywood truly lies.

🔗 Explore Our Export-Grade Plywood Solutions – Direct from HCPLY – Vietnam Plywood

As a leading Vietnam plywood manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood invites European and global buyers to explore our factory-produced plywood ranges. Every product below is manufactured at industrial scale with controlled core structure, stable quality, EU-ready compliance, and competitive factory-direct pricing.

🌳 Birch, Poplar & Engineered Interior Plywood

Discover our birch plywood Vietnam solutions, engineered specifically for EU furniture and interior applications where surface quality, stability, and repeatability matter most.

For lightweight and cost-efficient alternatives, our poplar plywood Vietnam and EV plywood Vietnam are widely adopted by furniture brands and OEM factories.

Interior producers looking for smooth finishing often choose matt plywood Vietnam from HCPLY – Vietnam Plywood, manufactured under strict thickness and sanding control.

🌲 Face Veneer & Decorative Plywood

For decorative and furniture-facing panels, HCPLY – Vietnam Plywood manufactures bintangor plywood Vietnam, okoume plywood Vietnam, and gurjan plywood Vietnam, all produced with transparent core structures and export-grade bonding.

Natural-look applications and packaging furniture components are well served by our pine plywood Vietnam, supplied directly from our factory lines.

🧱 Construction, Industrial & Packaging Plywood

For construction and infrastructure projects, European buyers rely on film faced plywood Vietnam and anti-slip plywood Vietnam manufactured by HCPLY – Vietnam Plywood for consistent load performance and surface durability.

Exporters and logistics operators choose our packing plywood Vietnam for cost efficiency, strength, and stable supply.

🌱 Core & Structural Strength Solutions

At the core of our manufacturing advantage is full control over raw materials. HCPLY – Vietnam Plywood produces core veneer Vietnam in-house, ensuring consistent density and bonding across all plywood ranges.

For high-strength applications, our eucalyptus plywood Vietnam delivers superior compression and bending performance while remaining export-optimized.

🏭 Why Global Buyers Choose HCPLY – Vietnam Plywood

As a large-scale Vietnam plywood manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood is chosen for:

- ✔️ Direct factory production (no trading risk)

- ✔️ Stable, repeatable quality at volume

- ✔️ Transparent core structure & specifications

- ✔️ EUTR / EUDR-ready documentation

- ✔️ Competitive pricing for long-term contracts

Whether you are sourcing birch plywood Vietnam, poplar plywood Vietnam, or industrial plywood by the container, HCPLY – Vietnam Plywood is your reliable manufacturing partner for sustainable, professional plywood supply.

👉 Contact our factory team to receive samples, technical data, and export quotations tailored to your market.