Anti-Termite & Anti-Mold Treatments in Vietnam Plywood

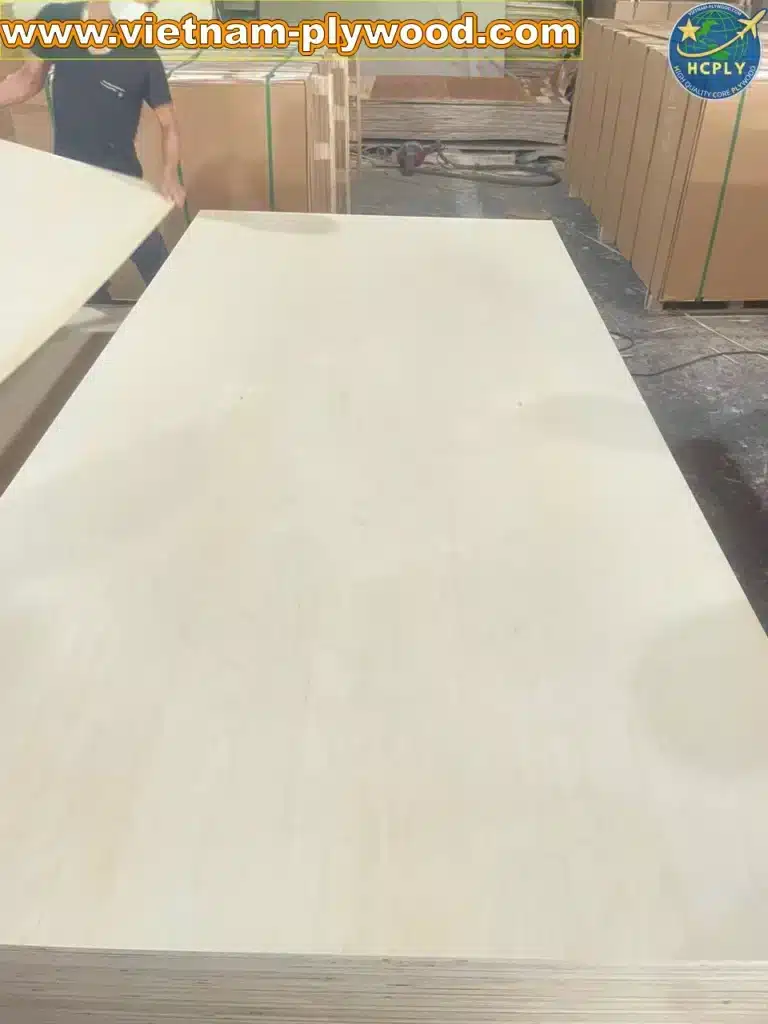

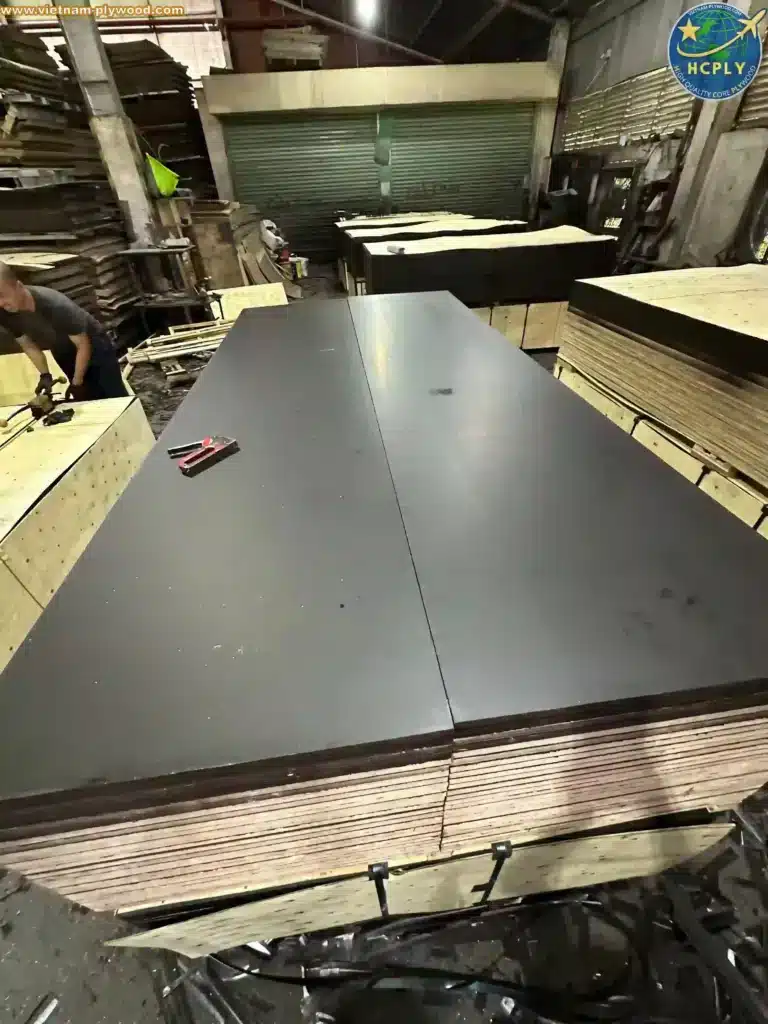

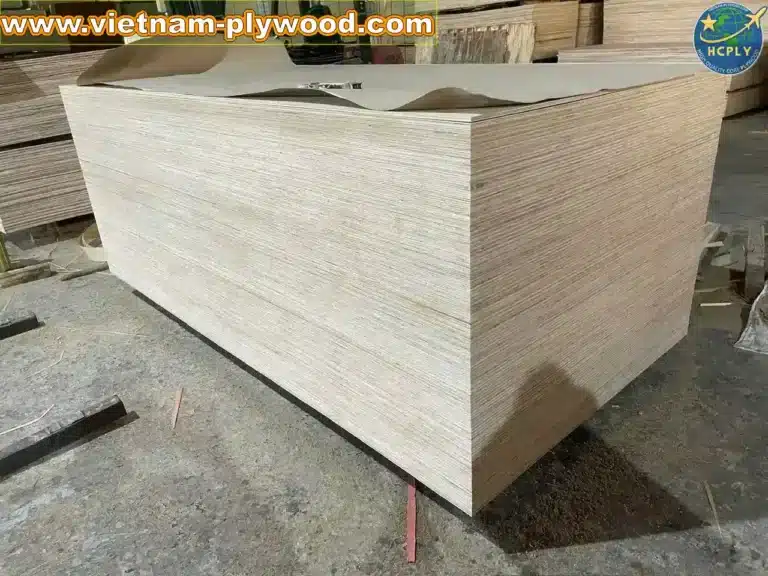

Termites and mold are two of the most common threats to plywood longevity, especially in tropical and humid climates. Vietnam plywood manufacturers use specialized anti-termite and anti-mold treatments to protect panels during storage, transport, and long-term use. These processes ensure that plywood remains durable, pest-free, and compliant with international standards.