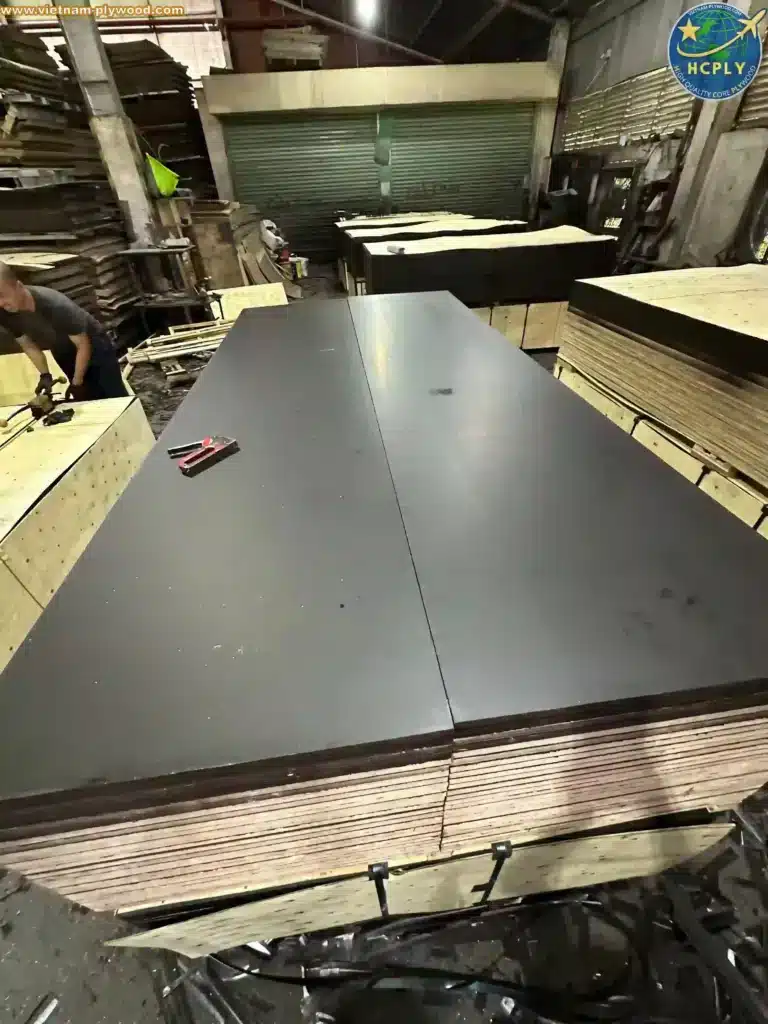

At the heart of every beautifully finished okoume veneer lies not only craftsmanship — but also the passion of those who make it possible. 🌳

At HCPLY, we don’t just manufacture plywood; we bring life, strength, and elegance into every panel we export from Vietnam.

Each shipment represents our promise: consistent quality, reliable partnership, and the spirit of Vietnamese craftsmanship reaching the world. 🌏

Let’s build the future of fine furniture and sustainable materials together — with HCPLY, your trusted plywood manufacturer and exporter in Vietnam. ❤️