Birch Plywood from Vietnam – Smart Alternative for European Importers After Russia & China

European plywood buyers are facing a historic shift.

With Russian birch plywood restricted by sanctions and Chinese plywood hit by anti-dumping duties exceeding 65%, importers across Europe are actively searching for a stable, legal, and cost-effective alternative.

Vietnam has emerged as the most strategic sourcing destination — and birch-faced plywood from Vietnam is now at the center of attention.

At HCPLY – Vietnam Plywood, we work directly with European buyers to bridge the gap between traditional Russian birch plywood and a new-generation solution:

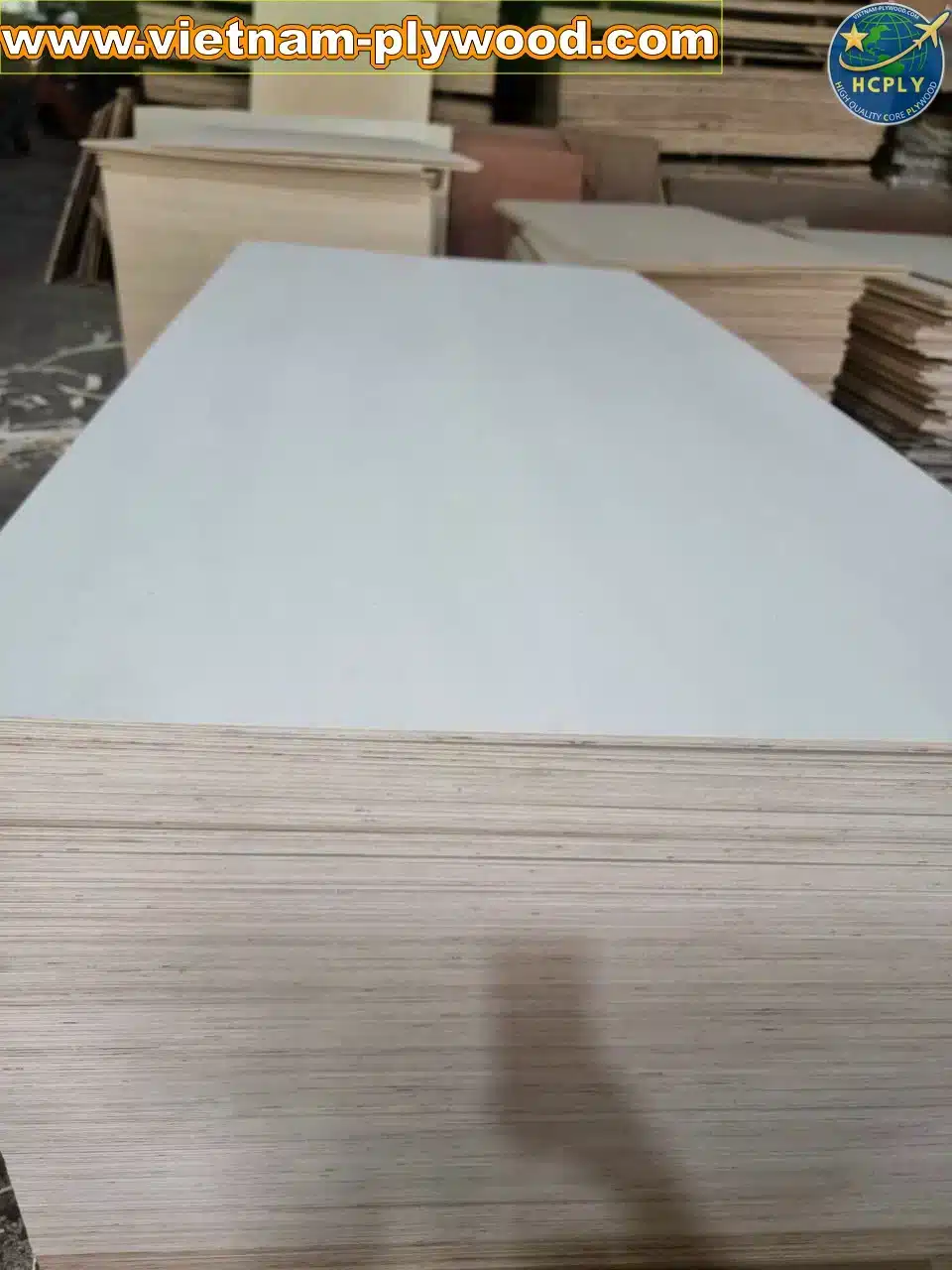

✔️ Birch veneer faces

✔️ Full white core alternatives (Styrax / Bồ Đề / Mỡ)

✔️ Competitive pricing — often 30–50% lower than Russian birch

✔️ Fully compliant with EU & US interior standards

This article explains why birch plywood from Vietnam is not a compromise — but a smarter evolution for European importers.

① 🌍 Europe’s Plywood Market Shift: Why Birch Plywood from Vietnam Is Gaining Momentum

European plywood importers are living through one of the largest sourcing transitions of the past two decades.

For years, Russian birch plywood and Chinese plywood dominated the European market. Russia supplied premium full birch panels with consistent density, while China covered the volume segment with aggressive pricing. That balance has now collapsed.

Geopolitical sanctions on Russia, combined with anti-dumping duties on Chinese plywood exceeding 65%, have fundamentally changed how European buyers think about risk, legality, and long-term supply security.

As a result, procurement managers are no longer asking “Where is the cheapest birch plywood?”

They are asking a much more strategic question:

“Which country can supply birch plywood legally, consistently, and at a competitive price for the next 5–10 years?”

This is exactly where birch plywood from Vietnam enters the conversation.

Vietnam is not a short-term replacement.

It is emerging as a structural alternative—offering birch-faced plywood engineered specifically for European interior standards, with transparent sourcing, stable production capacity, and pricing that remains competitive even under tightening EU trade regulations.

At HCPLY – Vietnam Plywood, we work directly with European importers, distributors, and furniture manufacturers who are actively transitioning away from Russia and China. What they are looking for is not a copy of the past—but a smarter evolution:

- ✔️ Legal, sanction-free supply

- ✔️ Stable production outside high-risk regions

- ✔️ Birch veneer appearance for premium interiors

- ✔️ Lightweight, white-core structures for modern furniture

- ✔️ Pricing starting from ~360 USD/CBM, often 2/3 to 1/2 the cost of Russian birch plywood

This article begins by explaining why the European market is shifting, before guiding buyers step-by-step through what birch plywood from Vietnam really is—and why it is becoming the preferred choice for forward-looking importers.

If you are sourcing for Europe today, this shift is not optional.

It is already happening.

② ⚖️ Anti-Dumping Duties Explained: Why Chinese Plywood Is No Longer Competitive in Europe

For many European importers, the turning point did not come from geopolitics alone —

it came from anti-dumping duties on Chinese plywood, which in some cases now exceed 65%.

This single policy change has reshaped the entire plywood sourcing strategy across the EU.

The reality behind anti-dumping duties

Anti-dumping duties are not temporary taxes.

They are long-term trade defense measures imposed when the EU determines that imported products are being sold below fair market value, damaging local industries.

For plywood imported from China, investigations over the past years have concluded that:

- Export prices were artificially low

- Subsidies distorted competition

- Traceability and origin verification were inconsistent

As a result, Chinese plywood now carries heavy additional duties, often calculated on top of:

- CIF value

- Regular customs duty

- VAT

What used to be “cheap plywood” is no longer cheap once it lands in Europe.

How 65%+ duties change the real landed cost

On paper, Chinese plywood may still look attractive.

In practice:

- A CIF price of 300–350 USD/CBM can turn into 480–550 USD/CBM or more

- Duty rates vary by exporter, creating pricing uncertainty

- Retroactive duty risks expose importers to unexpected liabilities

For professional buyers, this level of risk is unacceptable.

Procurement managers are not just comparing prices anymore —

they are calculating total landed cost + legal exposure + supply continuity.

Why European buyers are actively exiting China

Beyond cost, European importers face structural problems when sourcing from China today:

- ❌ Unpredictable duty enforcement

- ❌ Frequent regulation changes

- ❌ Increased customs scrutiny

- ❌ Higher documentation burden

- ❌ Reputation risk with downstream clients

In contrast, buyers increasingly favor origins with clear trade status, transparent documentation, and stable regulatory relationships with the EU.

This is exactly why sourcing strategies are shifting.

Vietnam’s position in the new trade landscape

Vietnam is not affected by the anti-dumping measures applied to Chinese plywood.

For European buyers, this means:

- ✅ No punitive anti-dumping duties

- ✅ Stable tariff structure

- ✅ Predictable landed cost

- ✅ Easier long-term contract planning

When combined with competitive manufacturing costs, Vietnam becomes not just an alternative —

but a strategic upgrade.

Why birch plywood from Vietnam benefits directly from this shift

As Chinese plywood loses its cost advantage, European buyers still need:

- Birch-look surfaces for interiors

- Light, white-core panels for furniture

- Compliance with EU interior standards

This demand does not disappear — it moves.

Birch plywood from Vietnam, engineered with birch veneer faces and full white core structures, steps in precisely where Chinese plywood can no longer compete.

And crucially:

- Pricing starts from ~360 USD/CBM

- No anti-dumping penalty

- No sanction risk

- No legal uncertainty

The strategic takeaway for European importers

Anti-dumping duties have turned China from a “low-cost option” into a high-risk source.

The smartest buyers are not waiting for policies to reverse.

They are already restructuring their supply chains toward:

- Vietnam

- Transparent manufacturing

- Long-term legal stability

This shift sets the stage for the next question every buyer asks:

If China is no longer viable — and Russia is sanctioned — where does birch plywood really come from now?

That question leads directly to the next block.

③ 🚫 Why Russian Birch Plywood Is No Longer a Viable Option for Europe

For decades, Russian birch plywood was considered the gold standard for European interior applications.

It offered high density, consistent strength, and the prestige of “full birch” construction — face and core from the same species. Many European furniture brands, shopfitting contractors, and panel distributors built their entire product lines around it.

That era has effectively ended.

Sanctions have changed more than supply — they changed risk

The restrictions placed on Russian-origin wood products are not just political statements.

They translate directly into operational and legal risk for European importers.

Today, importing Russian birch plywood involves:

- ❌ Sanction compliance uncertainty

- ❌ Banking and payment restrictions

- ❌ Insurance complications

- ❌ Heightened customs scrutiny

- ❌ Reputational risk with EU clients

Even when material is technically available through indirect routes, risk does not disappear — it compounds.

For professional buyers, this is no longer a sourcing challenge.

It is a risk management issue.

Indirect sourcing is not a real solution

Some buyers initially attempted to source “Russian birch” via third countries.

In reality, this approach introduces new problems:

- ⚠️ Origin traceability becomes unclear

- ⚠️ Documentation may not withstand EU audits

- ⚠️ Long-term contracts become impossible

- ⚠️ One investigation can disrupt entire supply chains

European importers increasingly understand that what cannot be audited cannot be scaled.

The structural problem: birch trees don’t grow everywhere

There is also a biological reality many buyers now face.

Birch trees suitable for plywood core growth are concentrated in:

- Northern Europe

- Russia

- Parts of Eastern Europe

They do not grow naturally in Vietnam or Southeast Asia.

This leads to an unavoidable conclusion:

👉 Vietnam cannot produce “full birch plywood” in the Russian sense.

And this is exactly where many buyers get confused.

The wrong question vs. the right question

The wrong question:

“Can Vietnam supply 100% full birch plywood like Russia?”

The right question:

“Can Vietnam supply a plywood solution that delivers the same performance and appearance — with lower risk and lower cost?”

This distinction is critical.

What European buyers actually need today

When we speak directly with European clients at HCPLY – Vietnam Plywood, their priorities are clear:

- ✔️ Birch appearance for premium interiors

- ✔️ Light, white core for modern furniture

- ✔️ Stable panels for CNC, lamination, and finishing

- ✔️ Predictable legality and documentation

- ✔️ Competitive pricing that protects margins

They are not chasing species purity.

They are chasing performance, compliance, and continuity.

Why Vietnam enters the picture now

Vietnam’s role is not to “replace Russia” one-to-one.

Vietnam’s role is to engineer a smarter alternative:

- Birch veneer where it matters — on the surface

- Optimized white core where weight and stability matter

- Manufacturing built for export, not domestic shortcuts

This is how birch plywood from Vietnam has emerged — not as a compromise, but as a redesign.

Cost reality: the final turning point

Even before sanctions, Russian birch plywood carried a premium.

Today, the gap is undeniable:

- Russian birch plywood: high price + high risk

- Birch plywood from Vietnam: starting from ~360 USD/CBM, often 2/3 to even 1/2 the total cost

For European buyers operating in competitive retail and contract markets, this difference is decisive.

The transition is already happening

Large importers are not waiting for Russian supply to normalize.

They are:

- Testing birch-faced plywood from Vietnam

- Adjusting specifications for white core solutions

- Locking long-term contracts with Vietnamese manufacturers

This is no longer a future trend.

It is a current migration.

The bridge to the next question

Once buyers accept that full Russian birch plywood is no longer viable, a new question naturally follows:

👉 If Vietnam does not have birch trees — what exactly is inside these panels, and how do they perform?

That question leads directly to the next block.

④ 🎯 What European Buyers Are Really Looking For Now (Beyond “Full Birch”)

After the shock of sanctions and anti-dumping duties, European buyers have entered a much more mature phase of sourcing.

The conversation has clearly shifted away from species purity toward performance, legality, and long-term stability.

In reality, most professional buyers today are not asking for “100% full birch like Russia” anymore.

Instead, they are redefining their priorities based on market pressure, customer expectations, and margin protection.

From species obsession to functional performance

Historically, “full birch plywood” was treated as a benchmark.

But in practice, what European manufacturers truly need is what birch plywood delivers, not necessarily where the tree comes from.

That includes:

- A clean, light-colored surface suitable for premium interiors

- Stable panels that perform well in CNC machining

- Consistent thickness and bonding for furniture production

- Predictable weight for logistics and assembly

- Reliable documentation for EU compliance and audits

When buyers step back and analyze usage, they quickly realize that face veneer + engineered core solves most real-world requirements.

Interior applications drive the new demand

The strongest demand today comes from:

- 🪑 Furniture manufacturers (flat-pack & custom)

- 🏬 Shopfitting and retail interior contractors

- 🏠 Cabinetry, wardrobes, and interior panels

- 📦 Premium packaging and display systems

In these applications, buyers value:

- Smooth birch appearance on the surface

- Lightweight structure to reduce handling and transport costs

- Low defect rates for visible finishes

- Compatibility with lamination, coating, or oil finishes

A birch-faced plywood with a white, lightweight core fits these needs exceptionally well.

Compliance is now non-negotiable

European buyers are under increasing pressure from:

- Customs authorities

- Retail chains

- Architects and project owners

- ESG and sustainability audits

This has changed purchasing behavior fundamentally.

Buyers now prioritize:

- ✅ Clear country of origin

- ✅ Transparent core composition

- ✅ Stable supply chains

- ✅ Consistent technical documentation

- ✅ Predictable landed cost (no surprise duties)

Vietnamese plywood suppliers that can offer traceable materials and export-grade manufacturing are therefore strongly favored.

Cost efficiency without sacrificing appearance

Another major shift is price sensitivity at scale.

With inflation, energy costs, and tighter margins across Europe, buyers are under pressure to optimize material cost per project, not per sheet.

This is where birch plywood from Vietnam becomes especially attractive:

- Birch-faced plywood starting from ~360 USD/CBM

- Often 2/3 or even 1/2 the cost of Russian birch plywood

- No sanction risk

- No anti-dumping exposure

For large-volume buyers, this difference can define whether a product line remains profitable.

The new buyer mindset (summary)

European buyers today are asking:

- “Will this panel look like birch on the finished product?”

- “Will it perform consistently in our production line?”

- “Can we import it legally for the next 5–10 years?”

- “Does it protect our margins at scale?”

When these questions are answered positively, the exact tree species in the core becomes far less critical.

This mindset sets the stage for the next essential topic:

👉 If Vietnam doesn’t have birch trees, what exactly replaces birch in the core — and how does it perform?

⑤ 🌱 Does Vietnam Have Full Birch Plywood? (An Honest, Clear Answer)

This is one of the most frequently asked questions from European buyers transitioning away from Russia:

“Can Vietnam supply full birch plywood – birch face and birch core – like Russian plywood?”

The honest answer is no.

And understanding why is far more important than the answer itself.

🌍 Birch Trees: A Geographic Reality, Not a Manufacturing Choice

Birch trees suitable for plywood core production grow naturally in:

- Northern Europe

- Russia

- Parts of Eastern Europe

They do not grow in Vietnam or anywhere in Southeast Asia due to climate and soil conditions.

This means:

- Vietnam cannot produce 100% birch-core plywood in the Russian sense

- Any claim of “full birch plywood from Vietnam” should be treated with caution

This transparency matters — especially for European buyers facing audits, origin checks, and ESG scrutiny.

❌ Why “Full Birch” Is No Longer the Right Benchmark

For many years, full birch became shorthand for quality.

But in today’s market, that benchmark is no longer practical:

- Russian birch is restricted by sanctions

- Alternative sources are limited and expensive

- Risk now outweighs material purity

European buyers are learning an important lesson:

The value of plywood lies in performance, not botanical purity.

🔍 What Buyers Actually Mean When They Ask for “Full Birch”

When buyers request full birch, they are usually looking for:

- Light-colored, clean appearance

- High surface quality for visible interiors

- Stable panels for CNC and lamination

- Consistent strength and screw holding

- Predictable weight and thickness

None of these requirements strictly require birch wood in the core.

They require smart engineering.

🇻🇳 Vietnam’s Role: Engineering, Not Imitation

Vietnam’s strength is not copying Russian plywood.

Vietnam’s strength is designing a modern alternative:

- Birch veneer on the surface (where it matters visually)

- Optimized white core inside (where weight and stability matter)

- Export-focused manufacturing with full documentation

This approach delivers the same functional outcome — often with:

- Lower weight

- Better cost control

- Lower supply risk

- Full EU compliance

💡 Why Honest Suppliers Say “No” First

At HCPLY, we deliberately start with clarity:

- ❌ We do not sell fake “full birch plywood”

- ✅ We explain what is technically possible

- ✅ We design solutions that meet real European needs

This honesty protects buyers from:

- Customs disputes

- Mislabeling risks

- Failed inspections

- Long-term sourcing problems

🧭 The Right Question to Ask Moving Forward

The question is no longer:

“Is this plywood 100% birch?”

The right question is:

“Does this plywood deliver the same appearance, performance, and compliance — at lower risk and lower cost?”

That question leads directly to Vietnam’s core innovation.

👉 In the next block, we explain what wood Vietnam uses instead of birch, and why Styrax full white core has become the preferred solution for European interiors.

⑥ 🌳 The Reality Check: Where Birch Trees Actually Grow (and Why It Matters)

One of the biggest misunderstandings among European buyers today is the assumption that birch plywood can be produced anywhere as long as the technology exists.

In reality, birch is not just a veneer choice — it is a geographic limitation.

Birch is a cold-climate hardwood

Birch trees suitable for structural plywood grow almost exclusively in cold and temperate regions, where long winters create slow growth and dense fiber structure.

This is why traditional full birch plywood has historically come from:

- Northern & Eastern Europe

- Russia

- Baltic states

- Parts of Scandinavia

These regions offer the natural conditions required for birch core production — conditions that simply do not exist in Southeast Asia.

Why birch does NOT grow in Vietnam

Vietnam’s climate is tropical to subtropical.

While this environment is excellent for fast-growing hardwoods, it is not suitable for birch trees, especially those needed for plywood cores.

This leads to a simple but critical truth:

❗ Vietnam does not and cannot produce birch core plywood in the Russian sense.

Any claim suggesting “100% full birch plywood made in Vietnam” should immediately raise questions about origin, legality, or mislabeling.

The mistake buyers often make

Many buyers initially ask:

“Can you supply full birch plywood like Russia?”

This question is understandable — but it is based on old supply logic.

The more important question today is:

“Can Vietnam supply a plywood solution that delivers the same appearance and performance — without sanctions, duties, or extreme cost?”

That shift in thinking changes everything.

Birch appearance vs. birch biology

In real-world interior applications, what matters most is not the tree species inside the core, but how the panel behaves:

- Surface appearance after finishing

- Weight for furniture and logistics

- Stability during CNC cutting

- Screw holding and bonding performance

- Compliance with EU interior standards

Birch veneer already delivers the visual and tactile identity buyers want on the surface.

The core’s role is to support performance — not to satisfy a botanical label.

Why this reality opens the door for smarter engineering

Once buyers accept that birch trees don’t grow in Vietnam, a more productive discussion begins:

- How can we replace birch core with functionally equivalent wood?

- Can we achieve lighter weight without sacrificing strength?

- Can we reduce cost while improving legality and supply security?

This is exactly where Vietnam’s engineered solutions come into play — and where full white core technologies begin to outperform traditional full birch in many interior uses.

👉 In the next block, we explain how Vietnam replaces birch core intelligently, rather than pretending to copy it.

⑦ 🧠 Vietnam’s Smart Solution: Birch Face + White Core (Engineered for Europe)

Once European buyers accept a fundamental truth — that full birch plywood (face + core) like Russia is no longer viable — the conversation finally becomes productive.

The question is no longer “Can Vietnam copy Russian birch?”

The real question is:

👉 How can Vietnam deliver the same visual, technical, and functional performance — with lower risk and far better cost control?

The answer is engineering, not imitation.

Birch Face: Preserve What the Market Actually Sees

In almost all interior and furniture applications, the face veneer defines value, not the hidden core.

That is why HCPLY – Vietnam Plywood focuses on birch veneer where it matters most:

- Clean, light birch grain for premium interiors

- Uniform color suitable for oil, lacquer, UV coating, and lamination

- Stable veneer quality optimized for CNC and finishing

- Consistent appearance across large batches

From the buyer’s perspective, this means:

✔️ The finished product looks like birch

✔️ Meets architect and designer expectations

✔️ Maintains brand positioning in European markets

The surface delivers the identity.

White Core: Optimize What the Market Never Sees — but Always Feels

Instead of forcing birch into the core (which is biologically and economically unrealistic), Vietnam applies white-core engineering using carefully selected hardwoods with similar functional behavior.

At HCPLY – Vietnam Plywood, we commonly use:

- Styrax / Bồ Đề / Mỡ (Full White Core)

- Optional combinations with eucalyptus or acacia depending on strength targets

These species are chosen not by name — but by performance profile.

Why White Core Outperforms Birch Core in Many Interior Uses

European buyers are often surprised to learn that, in real production environments, white-core plywood can outperform full birch in key areas:

Weight efficiency

- Lighter panels reduce transport cost

- Easier handling on furniture assembly lines

- Lower stress on joints and fittings

Stability

- Reduced internal tension compared to dense birch core

- Less warping in interior climate conditions

- More predictable CNC behavior

Bonding & machining

- Excellent glue penetration

- Clean edges after cutting

- Lower tool wear in mass production

For modern interior furniture, lighter + stable often beats heavier + dense.

Engineering, Not Substitution

This is not about “replacing birch with cheaper wood.”

It is about rebuilding plywood logic for today’s European market:

- Birch where appearance matters (face veneer)

- White core where weight, stability, and cost matter

- Manufacturing controlled for export standards, not domestic shortcuts

This is why buyers who test birch-faced plywood with white core often conclude:

“This is not a downgrade — it’s a smarter configuration.”

Cost Reality: Where the Advantage Becomes Strategic

The engineering approach unlocks a decisive cost advantage.

Typical comparison at scale:

- Russian full birch plywood

→ High material cost + sanctions + supply risk - Birch-faced plywood from Vietnam (white core)

→ Pricing from ~360 USD/CBM

→ Often 2/3 or even 1/2 of Russian birch total cost

For importers supplying furniture chains, retail interiors, or contract projects, this difference directly protects margins.

Why This Solution Fits Europe Now

This configuration aligns perfectly with current European priorities:

- ✔️ Sanction-free sourcing

- ✔️ No anti-dumping exposure

- ✔️ Stable, scalable production

- ✔️ Transparent documentation

- ✔️ Competitive long-term pricing

Most importantly, it aligns with how plywood is actually used today — not how it was specified 20 years ago.

HCPLY’s Role in This Transition

At HCPLY – Vietnam Plywood, we do not sell plywood by species name alone.

We work with European buyers to:

- Match face veneer to design intent

- Engineer core structure to application

- Balance weight, strength, and cost

- Ensure full compliance with EU interior standards

That is why our birch-faced, white-core plywood is not positioned as a compromise —

but as the logical next step after Russia & China.

👉 In the next block, we go deeper into the core itself — and explain what Styrax full white core really is, why it behaves the way it does, and why European buyers are rapidly adopting it.

⑧ 🌿 What Is Styrax Full White Core? (And Why Europe Is Choosing It)

Among all white-core solutions available in Vietnam, Styrax full white core has become the most requested option for European buyers seeking a true alternative to Russian birch plywood.

Understanding why requires looking beyond the name and into material behavior.

What exactly is Styrax wood?

Styrax (locally known as Bồ Đề or Cây Mỡ) is a fast-growing hardwood widely cultivated in Vietnam and neighboring regions.

Key characteristics:

- 🌱 Light-colored, naturally white wood

- 🌱 Fine, uniform grain structure

- 🌱 Low resin content

- 🌱 Excellent bonding behavior

Unlike mixed tropical hardwoods, Styrax offers predictability — a critical factor for export-grade plywood.

Density & weight: the biggest difference buyers feel immediately

Typical density ranges:

- Styrax full white core: ~480–520 kg/m³

- Russian birch core: ~650–700 kg/m³

This means:

- Panels are 20–30% lighter

- Handling becomes easier on production lines

- Transport cost per CBM decreases

- Large furniture components become more ergonomic

For flat-pack furniture and interior panels, this weight reduction is a major operational advantage.

Stability: designed for interior environments

Styrax performs exceptionally well in:

- Controlled indoor humidity

- Heated residential spaces

- Retail interiors

- Office furniture

- Hotel & hospitality projects

Benefits include:

- ✔️ Low internal stress

- ✔️ Reduced warping after machining

- ✔️ Consistent thickness across panels

- ✔️ Predictable behavior after lamination or coating

These properties align perfectly with EU interior standards.

Machining & finishing performance

European manufacturers often report that Styrax-core panels:

- Cut cleaner on CNC routers

- Produce fewer splinters on edges

- Require less sanding after machining

- Accept laminates and veneers more evenly

For high-volume furniture production, this translates into:

- Lower reject rates

- Faster production cycles

- More consistent quality output

Screw holding: a common concern addressed honestly

Styrax is lighter than birch, but this does not automatically mean weaker.

In practice:

- Screw holding is excellent for interior furniture

- Performance is more than sufficient for cabinets, wardrobes, shelving

- Not intended for heavy structural or exterior load-bearing use

This is why application clarity matters.

For interior-grade plywood, Styrax delivers the right balance of:

- Strength

- Weight

- Cost

Compliance & documentation advantages

Styrax used by HCPLY – Vietnam Plywood is:

- Plantation-grown

- Traceable by region

- Compatible with FSC-controlled sourcing

- Suitable for CARB P2 / E1 glue systems

This simplifies:

- EU customs clearance

- ESG documentation

- Customer audits

- Long-term supply agreements

Why European buyers increasingly prefer Styrax

When comparing function, risk, and cost, many buyers conclude:

- Russian birch core → strong but expensive and risky

- Styrax white core → optimized, lighter, legal, cost-efficient

Combined with birch veneer faces, Styrax core creates a panel that:

- Looks premium

- Performs reliably

- Costs significantly less

- Carries no geopolitical or trade risk

The strategic takeaway

Styrax full white core is not a compromise material.

It is a purpose-built solution for modern European interiors.

That is why it has become the default choice for:

- Furniture importers

- Interior contractors

- Retail fixture manufacturers

- Panel distributors across the EU

👉 In the next block, we will compare Russian birch plywood vs. Vietnam birch-faced plywood head-to-head — in weight, performance, and real landed cost.

⑨ ⚖️ Russian Birch vs. Vietnam Birch-Faced Plywood — A Real Comparison That Matters

When European buyers evaluate birch plywood from Vietnam, the most important step is a like-for-like comparison — not based on tradition, but on real usage, cost, and risk.

For years, Russian birch plywood was treated as the benchmark.

Today, that benchmark no longer reflects market reality.

Below is a practical comparison that European importers, furniture producers, and distributors are actually using to make decisions.

Material composition: purity vs. performance

Russian birch plywood

- Birch veneer on face and back

- Birch core throughout

- High density, heavy structure

- Strong reputation built over decades

Vietnam birch-faced plywood (HCPLY – Vietnam Plywood)

- Genuine birch veneer on face (where appearance matters)

- Engineered white core (Styrax / optional eucalyptus or acacia)

- Optimized density for interior use

- Designed for export, not legacy standards

👉 In modern interiors, the face defines value, while the core defines efficiency.

Weight & handling — a hidden cost many buyers ignore

Weight differences are immediate and measurable:

- Russian birch plywood: ~650–700 kg/m³

- Vietnam birch-faced plywood (white core): ~480–550 kg/m³

This translates into:

- Easier handling on production lines

- Lower transport cost per CBM

- Reduced strain on furniture joints

- Faster assembly for flat-pack systems

For large-scale furniture programs, weight reduction alone can reshape margins.

Performance in CNC & finishing

European manufacturers consistently report that birch-faced plywood from Vietnam:

- Cuts cleaner on CNC routers

- Produces fewer splinters on edges

- Requires less re-sanding

- Accepts laminates and coatings evenly

In contrast, dense birch core can increase:

- Tool wear

- Edge burning during machining

- Reject rates in high-speed production

For interior applications, predictability often beats brute density.

Price gap — where the decision becomes unavoidable

This is where the comparison turns decisive:

- Russian birch plywood

→ High base price

→ Sanction risk

→ Insurance & banking complications - Birch plywood from Vietnam

→ Pricing from ~360 USD/CBM

→ Often 2/3 to even 1/2 the total cost

→ No sanctions

→ No anti-dumping exposure

For importers supplying competitive EU markets, this gap defines survival.

The conclusion of Block 9

Russian birch plywood is no longer losing market share because of quality.

It is losing market share because:

- Risk has overtaken performance

- Cost has overtaken tradition

- Compliance has overtaken reputation

This naturally leads to the next question:

👉 If performance is comparable and cost is lower — how does this affect real-world applications?

⑩ 📐 Weight, Density & Performance — What European Buyers Feel After Installation

Numbers on a datasheet matter.

But what truly defines birch plywood from Vietnam is how it behaves after cutting, assembling, transporting, and installing.

This block explains why many European buyers report that Vietnam’s solution performs better in daily use.

Density is not the same as quality

For decades, density was equated with strength.

In reality:

- High density = heavier panels

- Heavier panels ≠ better interiors

Interior furniture and shopfitting require:

- Stability, not mass

- Consistency, not excess weight

- Controlled performance, not raw hardness

Vietnamese birch-faced plywood is engineered for functional density, not maximum density.

Stability under European interior conditions

White-core plywood (Styrax-based) performs exceptionally well in:

- Heated residential interiors

- Climate-controlled retail spaces

- Office furniture environments

- Cabinetry and wardrobes

Key benefits:

- Lower internal stress

- Reduced warping after machining

- Stable thickness across panels

- Predictable behavior over time

These are exactly the conditions where Russian birch is often over-engineered.

Screw holding — addressing the biggest concern directly

A common buyer fear is:

“Is white core weaker than birch?”

The honest answer:

- For interior furniture, screw holding is more than sufficient

- For heavy structural loads, birch core is still stronger — but unnecessary

Vietnam birch-faced plywood is optimized for:

- Cabinets

- Shelving

- Wardrobes

- Furniture carcasses

- Retail fixtures

Not for bridges or scaffolding.

Correct application equals correct performance.

Logistics & installation efficiency

Lower weight leads to:

- Reduced freight cost per container

- Easier manual handling on-site

- Faster installation cycles

- Lower risk of damage during transport

For European importers shipping thousands of panels, these savings compound quickly.

Performance summary (what buyers report)

European clients using birch plywood from Vietnam consistently highlight:

- ✔️ Easier processing

- ✔️ Lower reject rates

- ✔️ Cleaner finishes

- ✔️ Stable long-term behavior

- ✔️ Strong cost control

This explains why many buyers, after initial testing, do not return to Russian birch.

Bridge to the next blocks

Once weight, density, and performance are understood, the final decision becomes strategic:

👉 Who is this product actually best for — and who should still avoid it?

That is exactly what the next blocks will clarify.

⑪ 🧪 EU Interior Standards Compatibility — What Actually Matters in Compliance

For European buyers, compliance is no longer a checkbox — it is a purchasing condition.

After sanctions, anti-dumping duties, and increased customs inspections, importers are now evaluated not only on price and appearance, but on technical transparency and regulatory fit.

Birch plywood from Vietnam supplied by HCPLY – Vietnam Plywood is engineered specifically for EU interior standards, not legacy export shortcuts.

Key standards this product aligns with

European interior applications typically require:

- E1 / CARB P2 formaldehyde emission

- Stable bonding under EN 314-2 (interior use)

- Consistent thickness tolerance for CNC production

- Clear documentation of core species & origin

- Predictable behavior in climate-controlled environments

Our birch-faced plywood with white core is produced with:

- ✔️ E1 / CARB P2 glue systems (upon request)

- ✔️ Controlled moisture content (≤12%)

- ✔️ Press-calibrated thickness

- ✔️ Fully declared core composition (Styrax / eucalyptus / acacia)

- ✔️ Export QC designed for EU audits

Why this matters in real life

European buyers are increasingly asked to prove:

- What wood is inside the panel

- Where it comes from

- Why it is legally importable

- How it behaves over time indoors

This is where Vietnam’s engineered approach outperforms vague “full birch” claims with unclear origin.

⑫ ⚠️ Common Buyer Concerns — Answered Honestly (Warping, Color, Screw Holding)

European buyers transitioning from Russian birch usually ask the same critical questions.

We answer them directly — without marketing shortcuts.

❓ Will white core warp more than birch core?

No — for interior use, white core (Styrax) often shows less internal stress than dense birch.

Why?

- Lower density = lower tension

- More uniform grain

- Better behavior in heated indoor spaces

This results in:

- Reduced warping after CNC cutting

- More stable panels in furniture carcasses

- Predictable long-term performance indoors

❓ Is screw holding weaker?

White core is not designed for heavy structural loads — and it doesn’t need to be.

For:

- Cabinets

- Wardrobes

- Shelving

- Shopfitting

- Furniture frames

Screw holding is fully sufficient and reliable.

Using birch core for these applications often adds weight and cost without functional benefit.

❓ Is the color really comparable to birch?

Yes — because birch veneer defines what the market sees.

The face veneer delivers:

- Clean, light birch appearance

- Uniform grain for premium interiors

- Excellent finishing response (oil, lacquer, laminate)

The white core simply supports performance behind the surface.

⑬ 🎯 Who This Product Is Best For (And Who It Is NOT)

Birch plywood from Vietnam is not a universal replacement — and that clarity protects buyers.

✅ Ideal for:

- EU furniture manufacturers

- Flat-pack furniture brands

- Interior contractors

- Retail fixture producers

- Cabinet & wardrobe factories

- Importers replacing Russian or Chinese supply

Especially where:

- Appearance matters more than raw density

- Weight reduction improves logistics

- Cost control is critical

- Compliance risk must be minimized

❌ Not ideal for:

- Heavy structural construction

- Exterior load-bearing applications

- Marine or formwork use

Correct application = correct performance.

This product is designed for interior excellence, not over-engineering.

⑭ 💰 Price Reality — Why Buyers Are Switching at Scale

Once performance and compliance are clear, pricing becomes the final accelerator.

Real market comparison (FOB)

- Russian full birch plywood

→ High base cost

→ Sanction risk

→ Insurance & banking issues - Birch plywood from Vietnam (HCPLY – Vietnam Plywood)

→ Prices from ~360 USD/CBM

→ Often 2/3 or even 1/2 of Russian landed cost

→ No sanctions

→ No anti-dumping exposure

For large-volume importers, this difference is not incremental — it is strategic.

Many buyers do not switch because Vietnamese birch is cheaper.

They switch because Russian birch is no longer sustainable.

⑮ 🧭 Final Takeaway — The Smart Alternative After Russia & China

Birch plywood from Vietnam is not about copying the past.

It is about re-engineering plywood for today’s European reality.

At HCPLY – Vietnam Plywood, we do not sell myths.

We deliver:

- ✔️ Birch appearance where it matters

- ✔️ White core where efficiency matters

- ✔️ Legal, transparent sourcing

- ✔️ Stable export-grade production

- ✔️ Competitive pricing from ~360 USD/CBM

This is why European buyers are no longer asking:

“Is this 100% birch like Russia?”

They are asking:

“Can this panel protect our margins, pass audits, and perform consistently for the next 5–10 years?”

That question leads to Vietnam.

👉 Contact HCPLY – Vietnam Plywood to request specifications, samples, or pricing for birch-faced plywood engineered for the EU market.

🔗 Explore More Export-Grade Plywood Solutions from HCPLY – Vietnam Plywood

If you are evaluating birch plywood from Vietnam as a strategic replacement after Russia and China, it’s also worth exploring other export-grade plywood options engineered by HCPLY – Vietnam Plywood to meet European and global demand.

Each product below is manufactured for stable quality, transparent sourcing, and competitive pricing, with flexible core options such as Styrax full white core, eucalyptus, and acacia:

👉 Birch Plywood Vietnam

Premium birch-faced plywood engineered for EU interiors — lightweight, stable, and cost-efficient.

👉 Poplar Plywood Vietnam

Clean, light-colored panels ideal for furniture, cabinets, and interior applications.

👉 EV Plywood Vietnam

Decorative EV (engineered veneer) plywood with modern appearance at a highly competitive cost.

👉 Gurjan Plywood Vietnam

High-density plywood trusted by Indian and Asian markets for strength-focused applications.

👉 Film Faced Plywood Vietnam

Export-grade shuttering plywood for construction and formwork projects worldwide.

👉 Okoume Plywood Vietnam

Lightweight, smooth-faced plywood widely used in furniture and interior design.

👉 Core Veneer Vietnam

The foundation of quality plywood — white core, eucalyptus, and acacia veneers produced in-house.

👉 Packing Plywood Vietnam

Cost-effective plywood solutions for crates, pallets, and industrial packaging.

💡 One supplier. Multiple solutions. One consistent standard.

From birch-faced panels to EV plywood and film faced plywood, HCPLY – Vietnam Plywood delivers engineered plywood that protects your margins, meets compliance, and scales reliably for international markets.

👉 Contact us to compare samples, specifications, and FOB pricing across our full plywood range.

❓ Quick FAQ – Birch Plywood from Vietnam (Buyer-Oriented)

Is birch plywood from Vietnam the same as Russian full birch plywood?

No. Vietnam does not grow birch trees for plywood core. Instead, Vietnamese manufacturers use birch veneer on the face combined with engineered white core materials that deliver similar performance for interior applications, with far lower risk and cost.

Why are European buyers accepting birch-faced plywood instead of full birch?

Because most interior and furniture applications depend on surface appearance, panel stability, and machinability, not species purity of the core. Birch-faced plywood from Vietnam meets these functional needs while avoiding sanctions and anti-dumping risks.

What core materials are used instead of birch in Vietnam?

Common options include Styrax (Bồ Đề / cây mỡ) full white core for lightweight interiors, or eucalyptus core for higher density and screw-holding strength, depending on project requirements.

Is birch plywood from Vietnam compliant with EU interior standards?

Yes. When manufactured for export, birch plywood from Vietnam can meet E0/E1 glue standards, CARB P2, and other EU interior requirements, with clear origin documentation.

Why is the price significantly lower than Russian birch plywood?

Because Vietnam avoids high-cost birch logs, sanctions, and trade risks. Pricing typically starts from ~360 USD/CBM, often 2/3 or even 1/2 the total cost of Russian birch plywood delivered to Europe.