In Europe, safety is not optional — it is engineered.

Across construction sites, logistics centers, truck flooring, scaffolding platforms, and industrial walkways, European buyers demand one thing above all: reliable anti-slip plywood that performs consistently under load, moisture, and time.

As a leading manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood produces export-grade anti-slip plywood Vietnam designed specifically for European performance standards — not generic construction use.

Our non slip plywood Europe programs are built on controlled core engineering, premium phenolic or cost-optimized melamine glue systems, and certified AICA anti-slip film surfaces. Every panel is manufactured under strict process control, ensuring stability, bonding strength, and long-term durability across demanding applications.

This is not trading plywood.

This is industrial anti-slip plywood manufactured at scale, exported directly from Vietnam by HCPLY – Vietnam Plywood, trusted by European importers who require safety, compliance, and price stability.

Anti-Slip Plywood Vietnam – High Performance Non-Slip Film Faced Plywood for Europe | HCPLY – Vietnam Plywood

1 – European demand for anti-slip plywood has shifted rapidly toward Vietnam — not by chance, but by performance and process advantage.

As a professional manufacturer and exporter, HCPLY – Vietnam Plywood works directly with European buyers who prioritize safety, consistency, and long-term supply security over short-term price fluctuations.

Anti-slip plywood Vietnam manufactured by HCPLY – Vietnam Plywood offers a unique balance that European buyers require:

🟢 Certified anti-slip surfaces for safety-critical applications

🟢 Engineered core options for weight, strength, and cost control

🟢 Phenolic or melamine glue systems matched to real usage conditions

🟢 Full compliance with CARB P2, CE, FSC, EUDR, and EUTR requirements

🟢 Factory-direct pricing with scalable export capacity

Unlike many suppliers, HCPLY – Vietnam Plywood controls the entire manufacturing process — from core veneer selection and drying, to glue formulation, hot pressing, film lamination, and export packaging.

This manufacturing control is the foundation that allows European buyers to trust Vietnam as a long-term source for non slip plywood Europe, replacing higher-risk or higher-cost origins.

➡️ In the next section, we will examine the core structure options that define performance, weight, and cost in anti-slip plywood Vietnam — and why core choice matters more than most buyers realize.

🟦 02. Core Structure Options – The Foundation of Anti-Slip Performance

In anti-slip plywood, the core is not a hidden detail — it is the structural backbone that defines load capacity, durability, and long-term safety. As a leading manufacturer and exporter, HCPLY – Vietnam Plywood engineers anti-slip plywood cores specifically for European industrial and construction requirements, not generic use.

🪵 Acacia Core – Cost-Efficient & High Bonding Strength

Acacia core anti-slip plywood is widely chosen by European buyers who require balanced performance with optimized cost.

- Density: 550–600 kg/m³

- Key advantages:

- Lightweight compared to eucalyptus

- Excellent veneer bonding and glue penetration

- Stable panel structure under repetitive load

- Ideal for:

- Truck flooring

- Scaffolding platforms

- Temporary construction walkways

💡 Acacia core allows competitive pricing while still meeting strict European safety expectations when combined with premium film and glue systems.

🌳 Eucalyptus Core – Maximum Strength & Structural Integrity

For projects where load-bearing capacity and compression resistance are critical, eucalyptus core anti-slip plywood is the premium solution engineered by HCPLY – Vietnam Plywood.

- Density: 650–750 kg/m³

- Mechanical performance:

- High compression resistance

- Excellent MOR / MOE values

- Superior elasticity and impact resistance

- Advantages:

- Minimal deformation under heavy loads

- Outstanding flatness and long-term stability

- Ideal for:

- Heavy-duty industrial flooring

- Logistics centers

- Long-term outdoor or high-moisture applications

⚠️ Eucalyptus core panels are heavier and approximately USD +30/CBM higher than acacia, but deliver unmatched structural confidence.

🧠 Engineered Core Selection by HCPLY – Vietnam Plywood

Unlike traders, HCPLY – Vietnam Plywood controls veneer sourcing, drying, grading, and layup orientation. Each core option is engineered to match:

- Load requirements

- Usage duration

- Climate exposure

- Target budget

This is why European buyers rely on HCPLY – Vietnam Plywood as a long-term manufacturer, supplier, and exporter of anti-slip plywood Vietnam — not just a short-term supplier.

➡️ In the next section, we will analyze phenolic vs melamine glue systems and explain how adhesive choice directly impacts waterproof performance, lifespan, and total project cost.

🟦 03. Glue Systems – Phenolic vs Melamine in Anti-Slip Plywood

In anti-slip plywood, glue selection is a decisive engineering factor, not a secondary cost option. As a large-scale manufacturer and exporter, HCPLY – Vietnam Plywood designs glue systems based on real European usage conditions, ensuring safety, durability, and compliance across transport, construction, and industrial flooring applications.

European buyers typically choose between phenolic glue and melamine glue, each serving different performance and budget objectives.

🧪 Phenolic Glue (WBP) – Maximum Waterproof & Structural Performance

Phenolic glue is the standard choice for high-performance anti-slip plywood Europe, especially in applications exposed to moisture, repeated load cycles, and long service life.

Key characteristics:

- 🔒 Exceptional water resistance (WBP standard)

- 🌧️ Stable bonding under rain, humidity, and temperature fluctuation

- 🧱 High shear strength for heavy-duty load-bearing

- 🔥 Superior durability for long-term outdoor and industrial use

Manufacturing requirement (critical):

- ✔️ Core veneers must be kiln-dried before pressing

- ✔️ Moisture content strictly controlled

- ✔️ Pressing cycle optimized for phenolic curing

At HCPLY – Vietnam Plywood, phenolic anti-slip plywood is manufactured under controlled drying and pressing protocols, ensuring:

- Zero delamination risk

- Long-term bonding integrity

- Stable performance across European climates

💰 Price level: from ~490 USD/CBM, depending on core type and thickness

🎯 Best for: truck flooring, scaffolding decks, logistics platforms, outdoor walkways

🧪 Melamine Glue – Cost-Optimized & Performance-Balanced Solution

For projects where full waterproof exposure is not required, melamine glue offers a reliable and more economical alternative.

Key characteristics:

- 💧 Good moisture resistance for semi-exposed conditions

- ⚖️ Strong bonding when paired with quality core veneers

- 💰 Cost saving of 50–80 USD/CBM compared to phenolic glue

- 🧩 Suitable for controlled environments

When engineered correctly by HCPLY – Vietnam Plywood, melamine-bonded anti-slip plywood still meets European safety expectations for:

- Indoor industrial flooring

- Covered transport platforms

- Temporary construction use

💰 Price level: from ~420 USD/CBM with acacia core

🎯 Best for: cost-sensitive European projects with controlled exposure

⚙️ Glue System Selection – Engineered, Not Arbitrary

Unlike trading suppliers, HCPLY – Vietnam Plywood does not “offer glue types” generically.

Each glue system is engineered based on:

- Core species (acacia or eucalyptus)

- Load intensity and duration

- Moisture exposure level

- Project lifespan expectations

- Buyer’s total cost strategy

This manufacturing-driven approach is why European importers rely on HCPLY – Vietnam Plywood as a trusted manufacturer, supplier, and exporter of anti-slip plywood Vietnam, not just a price-based source.

➡️ In the next section, we will examine AICA anti-slip film specifications (220g mesh & 130g smooth) and explain how surface design directly impacts grip, wear resistance, and safety compliance.

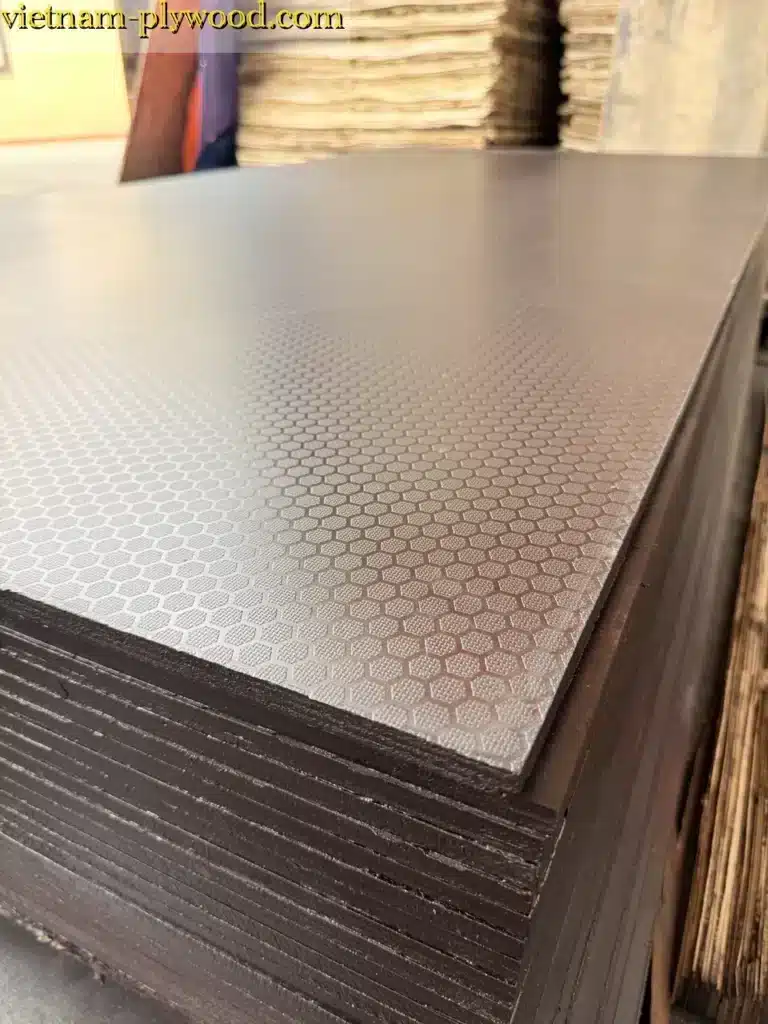

🟦 04. Anti-Slip Film Surface Technology – Grip, Wear Resistance & Safety Compliance

In anti-slip plywood, surface technology is the first line of safety. For European buyers, slip resistance is not aesthetic — it is a regulated performance requirement. As a large-scale manufacturer and exporter, HCPLY – Vietnam Plywood engineers anti-slip plywood Vietnam using certified AICA film systems, designed to deliver consistent grip, abrasion resistance, and long service life under demanding European conditions.

🧱 Certified AICA Anti-Slip Film – Engineered for Europe

All anti-slip plywood manufactured by HCPLY – Vietnam Plywood uses Japanese AICA film, a benchmark in European non-slip applications.

- Film weight (phenolic overlay):

- 🟩 220 g/m² – anti-slip surface

- ⚪ 130 g/m² – smooth back face

- High resin saturation for:

- Long-term wear resistance

- Stable friction coefficient

- Resistance to moisture, oil, and dirt

This combination ensures panels remain safe and functional even after repeated use in transport, construction, and industrial environments.

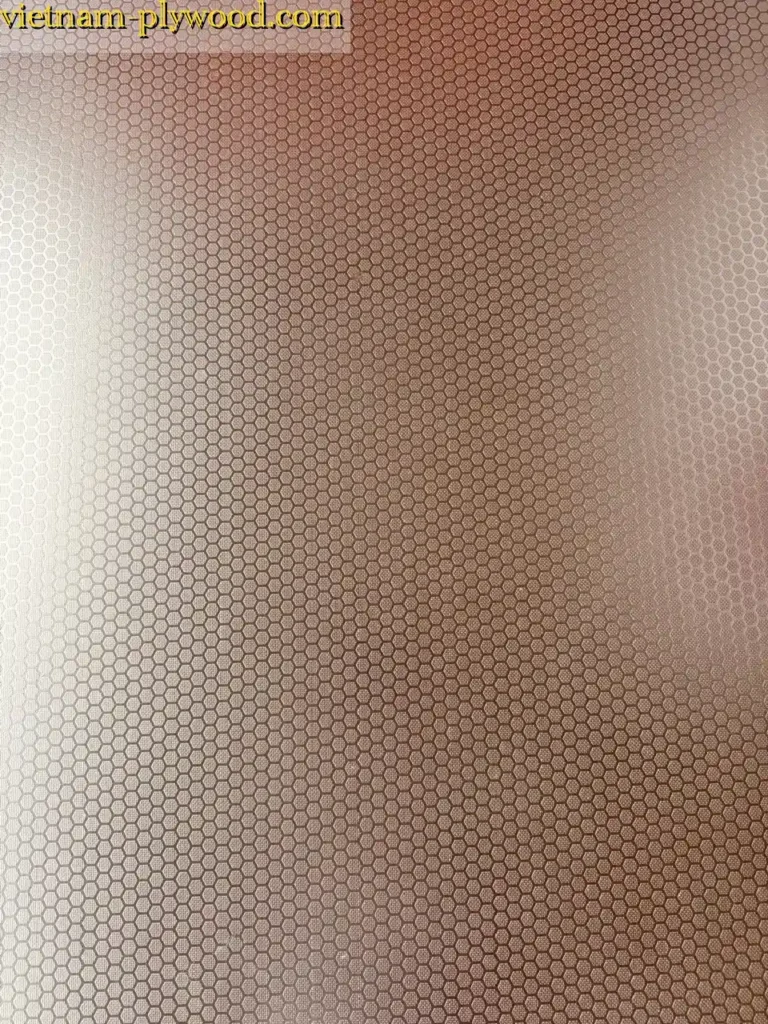

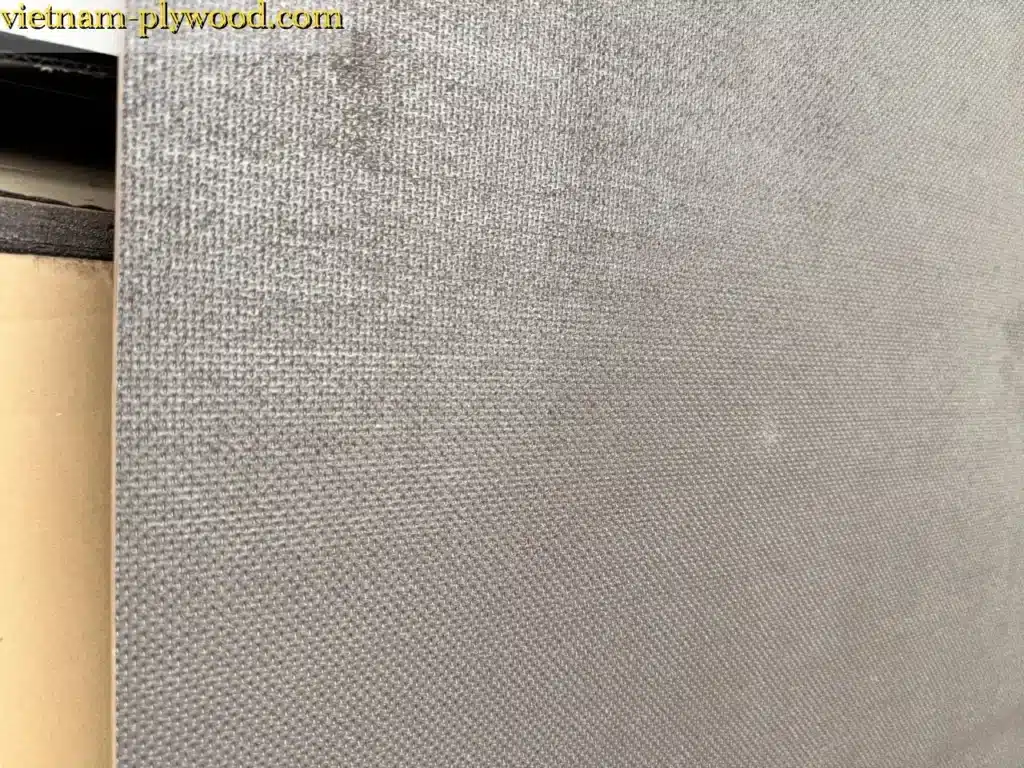

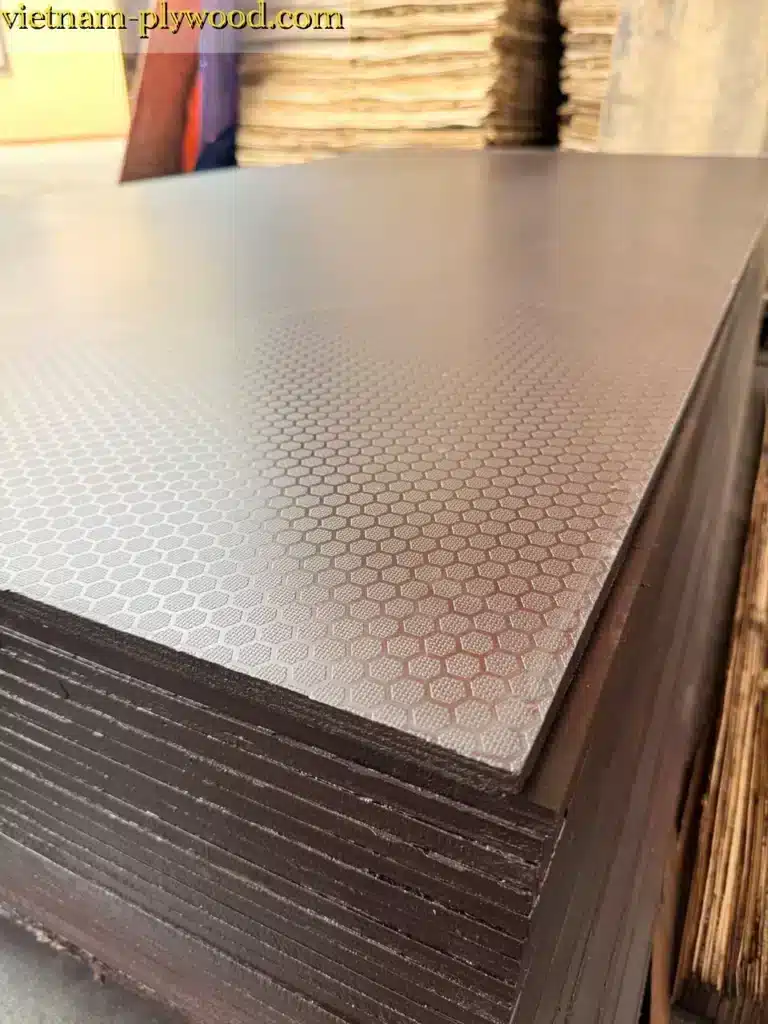

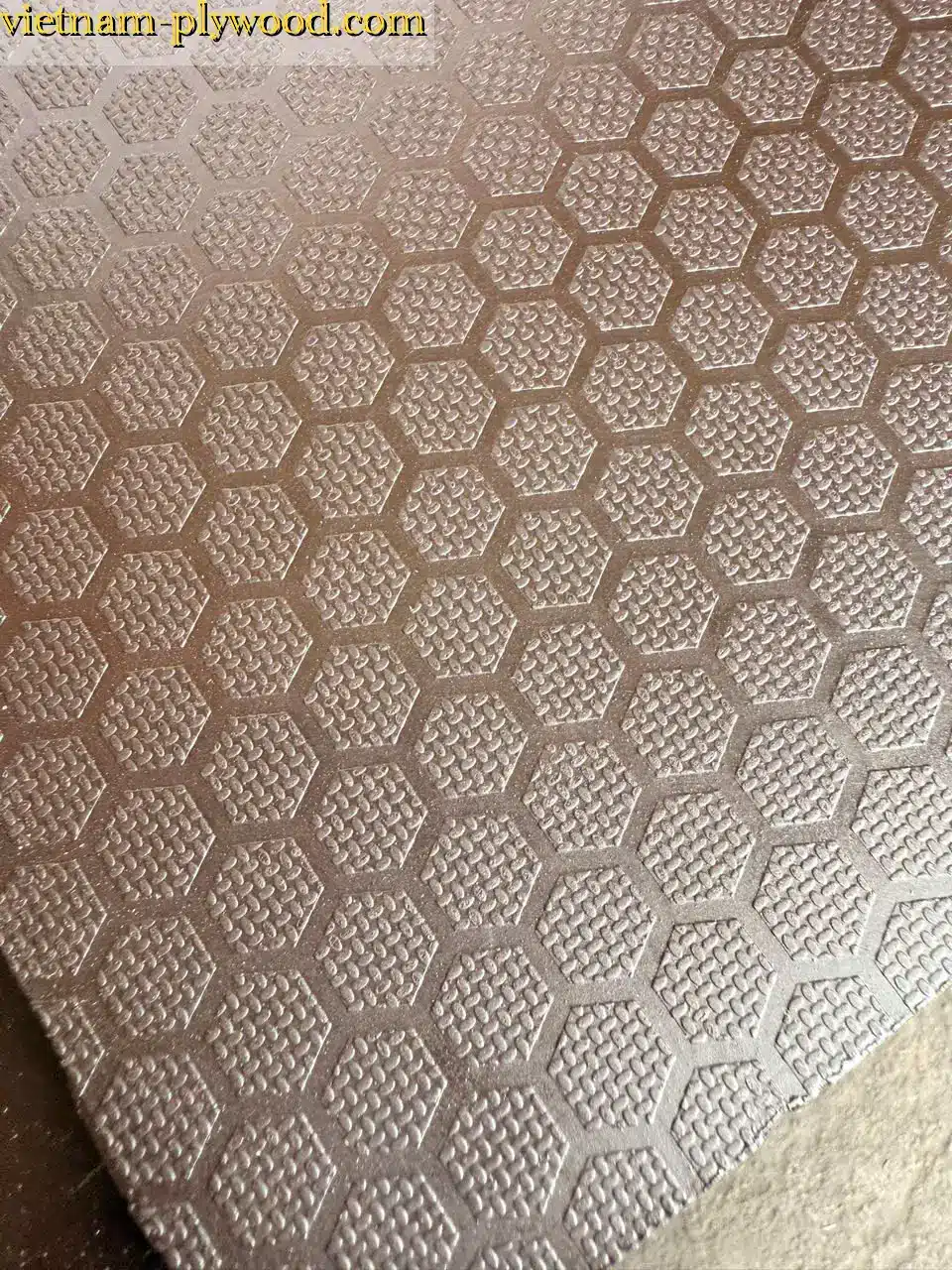

🔷 Two Anti-Slip Surface Patterns – Same Safety, Same Cost

To meet different application preferences without compromising performance, HCPLY – Vietnam Plywood offers two professional anti-slip textures, both manufactured at 220 g/m² with equivalent pricing:

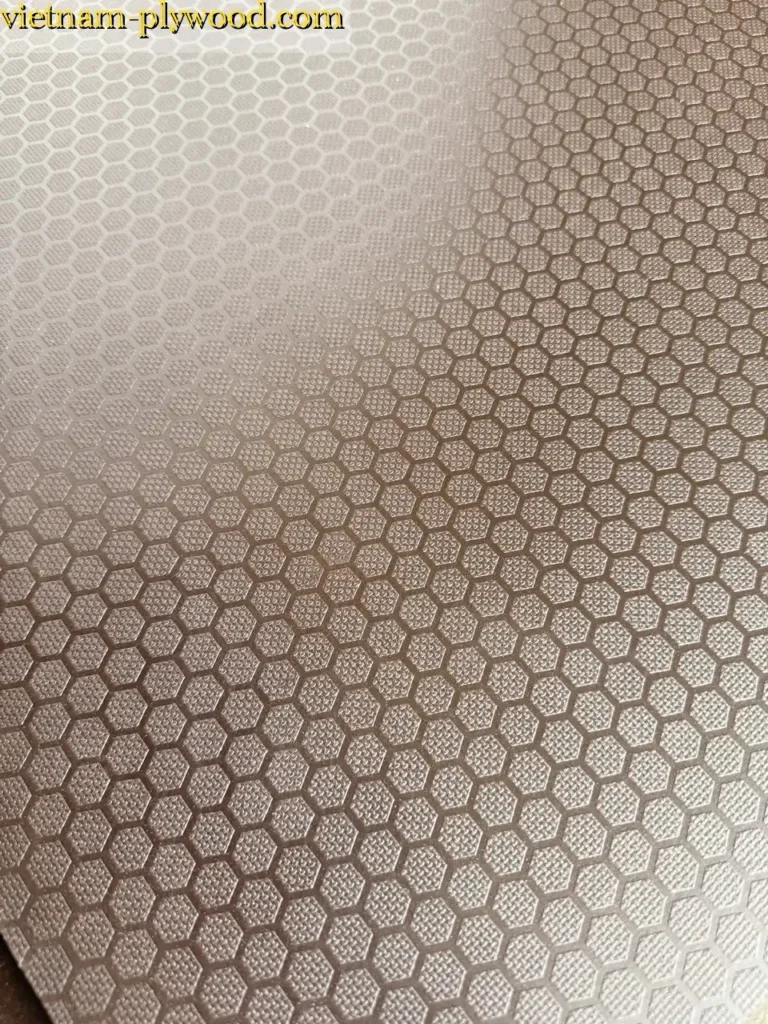

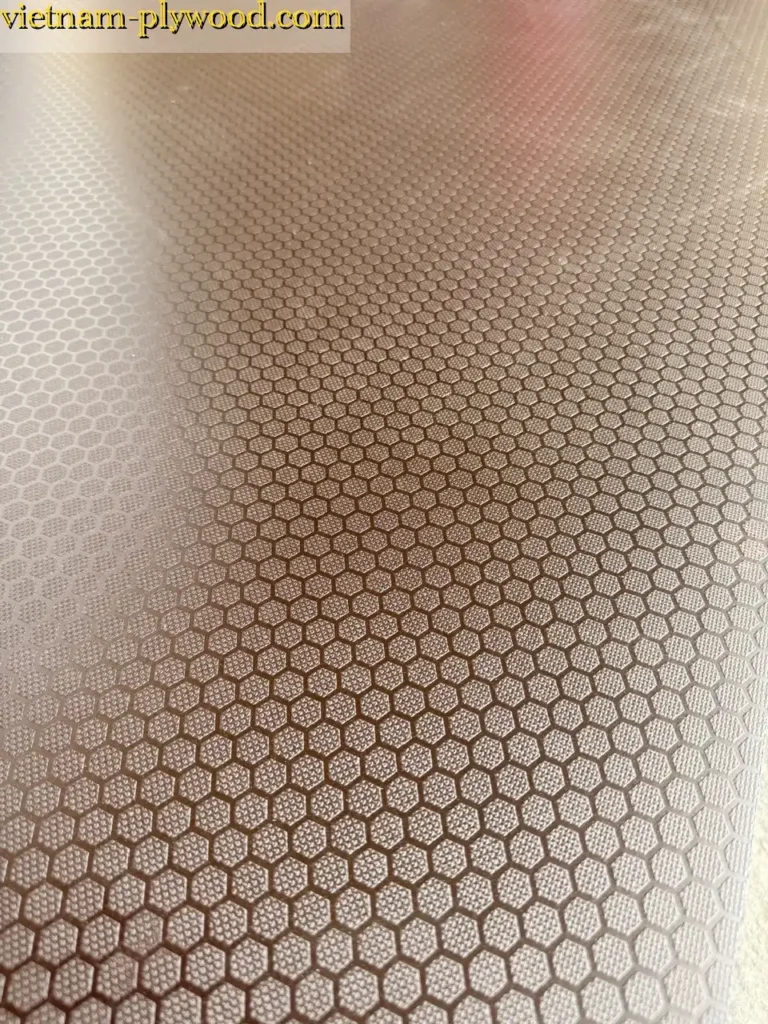

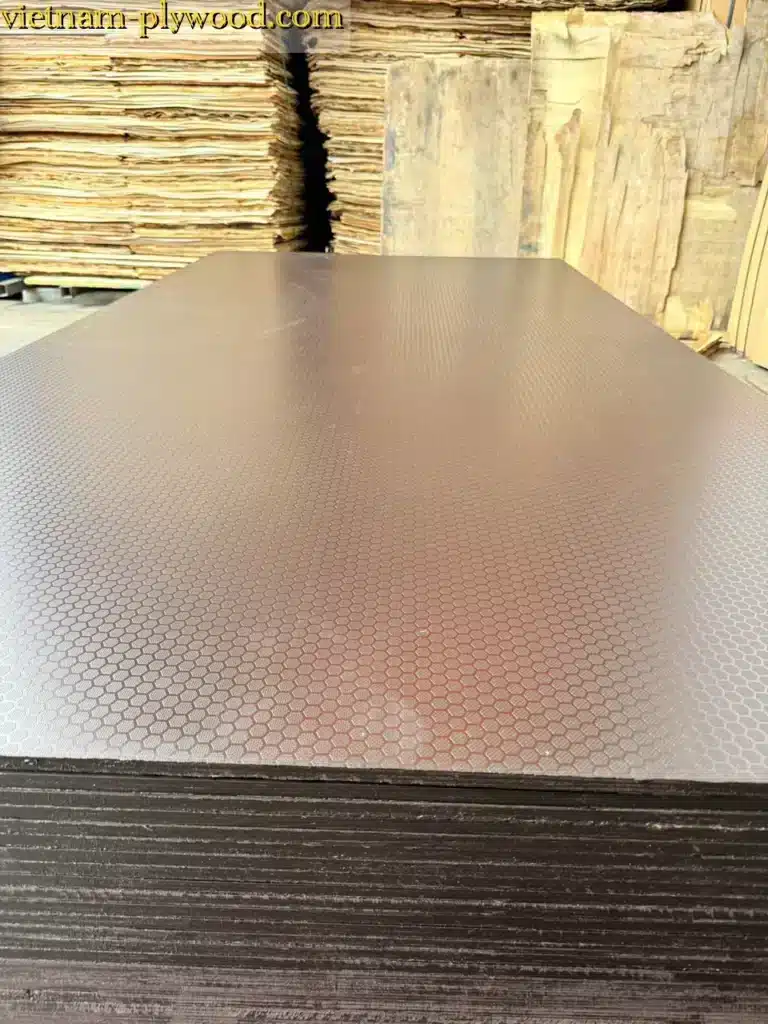

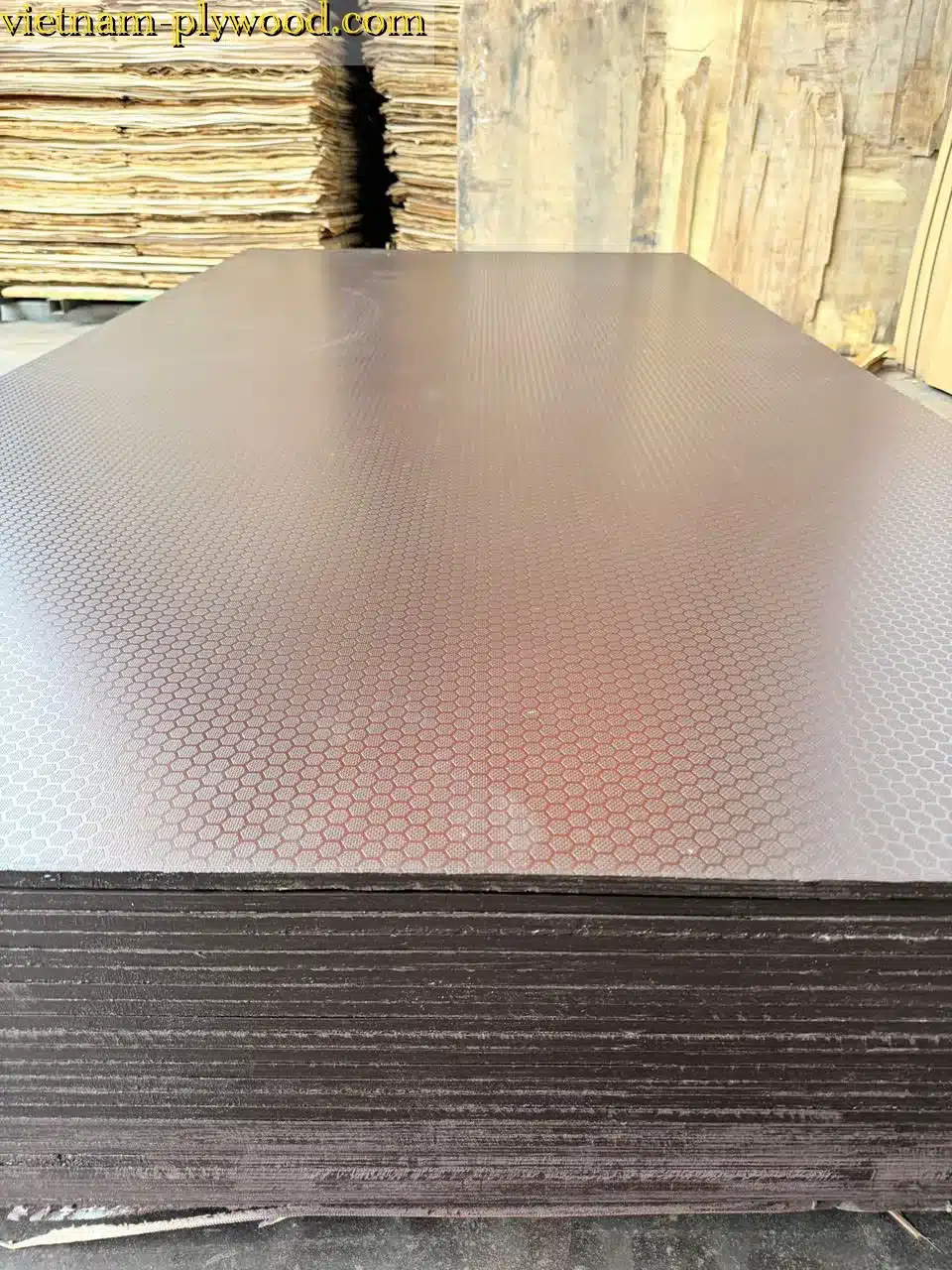

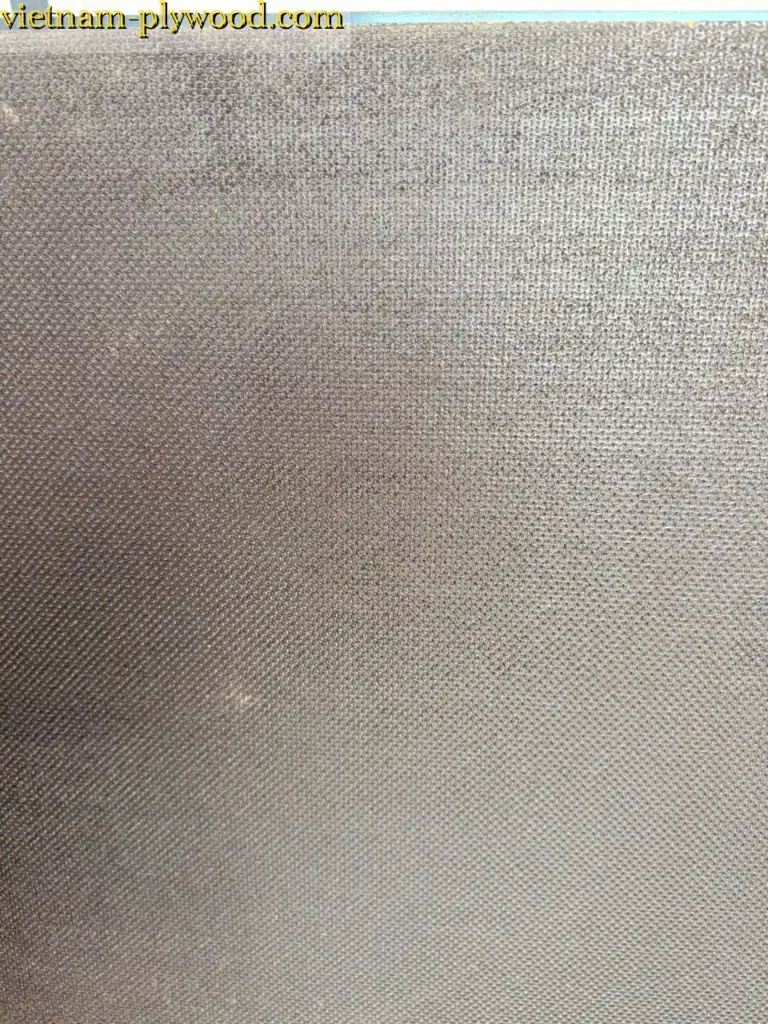

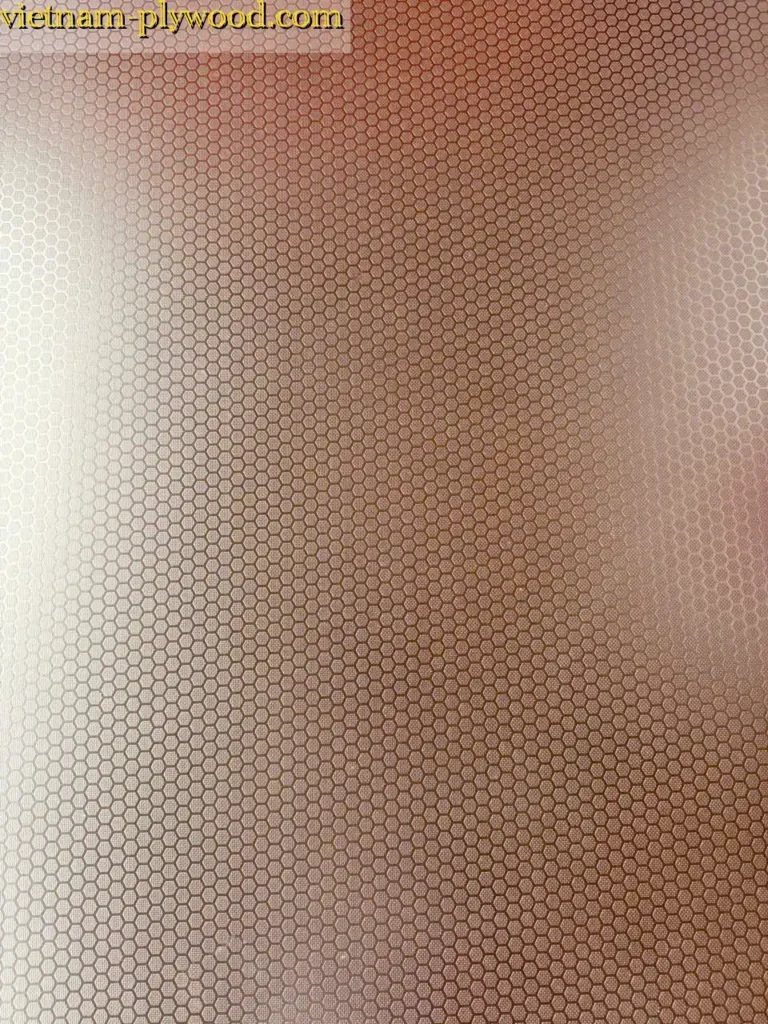

🔹 Hexa Pattern (Hexagonal / Wire Mesh)

- Aggressive, high-grip surface

- Excellent traction under wet or muddy conditions

- Preferred for:

- Truck & trailer flooring

- Scaffolding decks

- Outdoor construction platforms

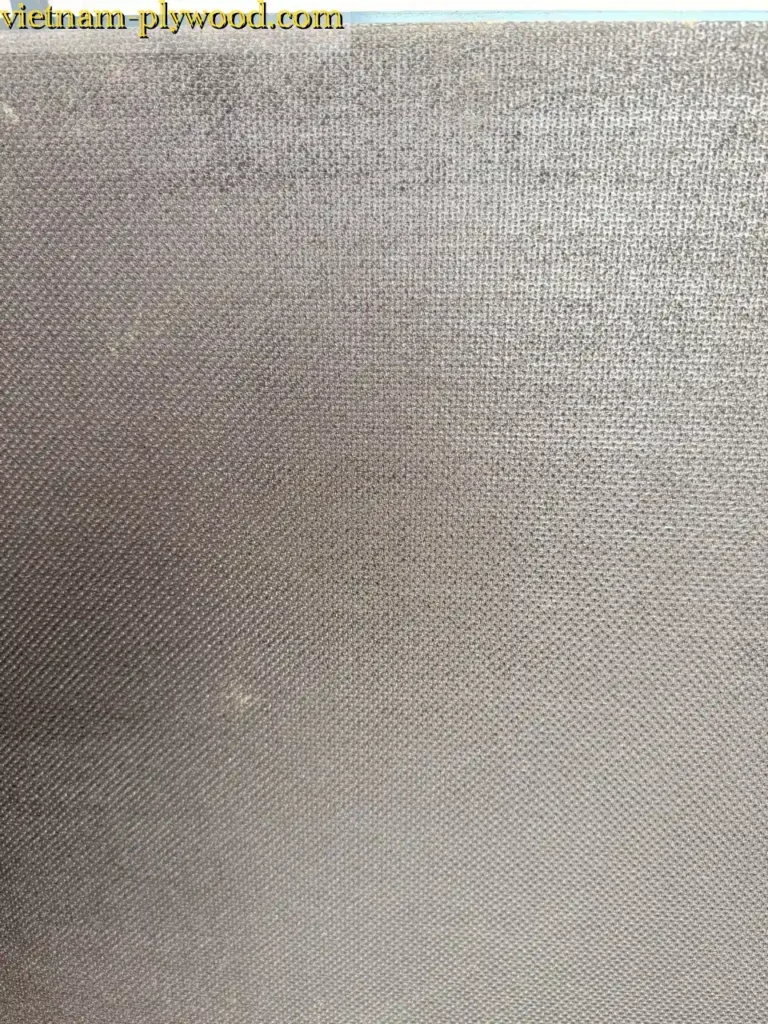

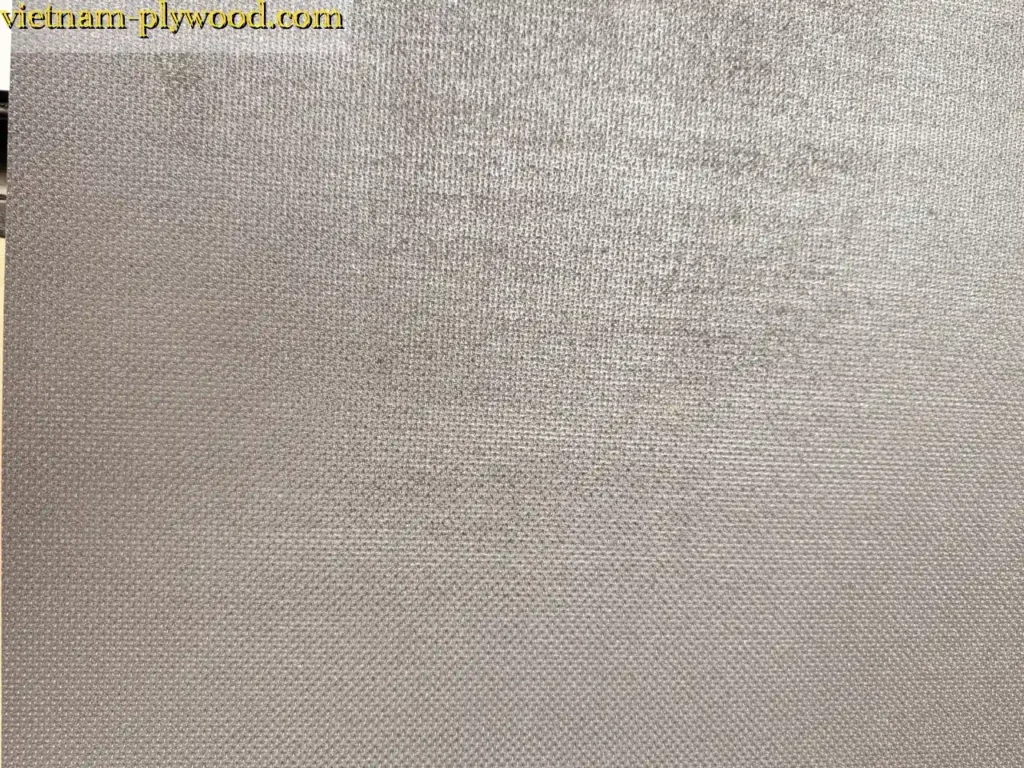

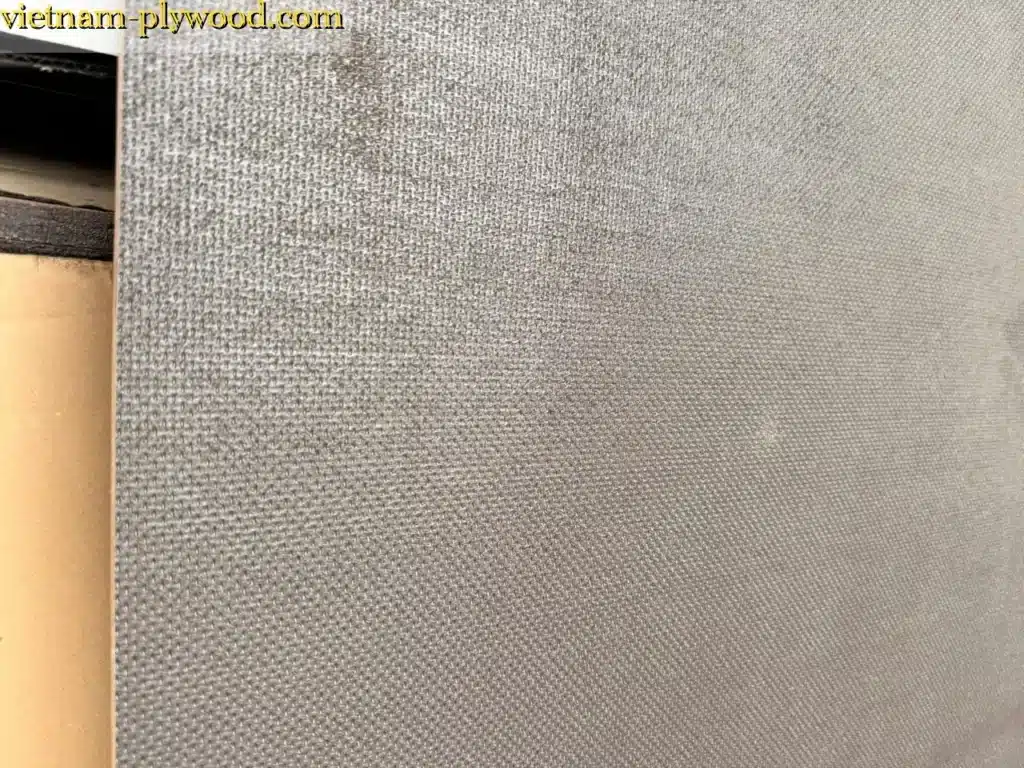

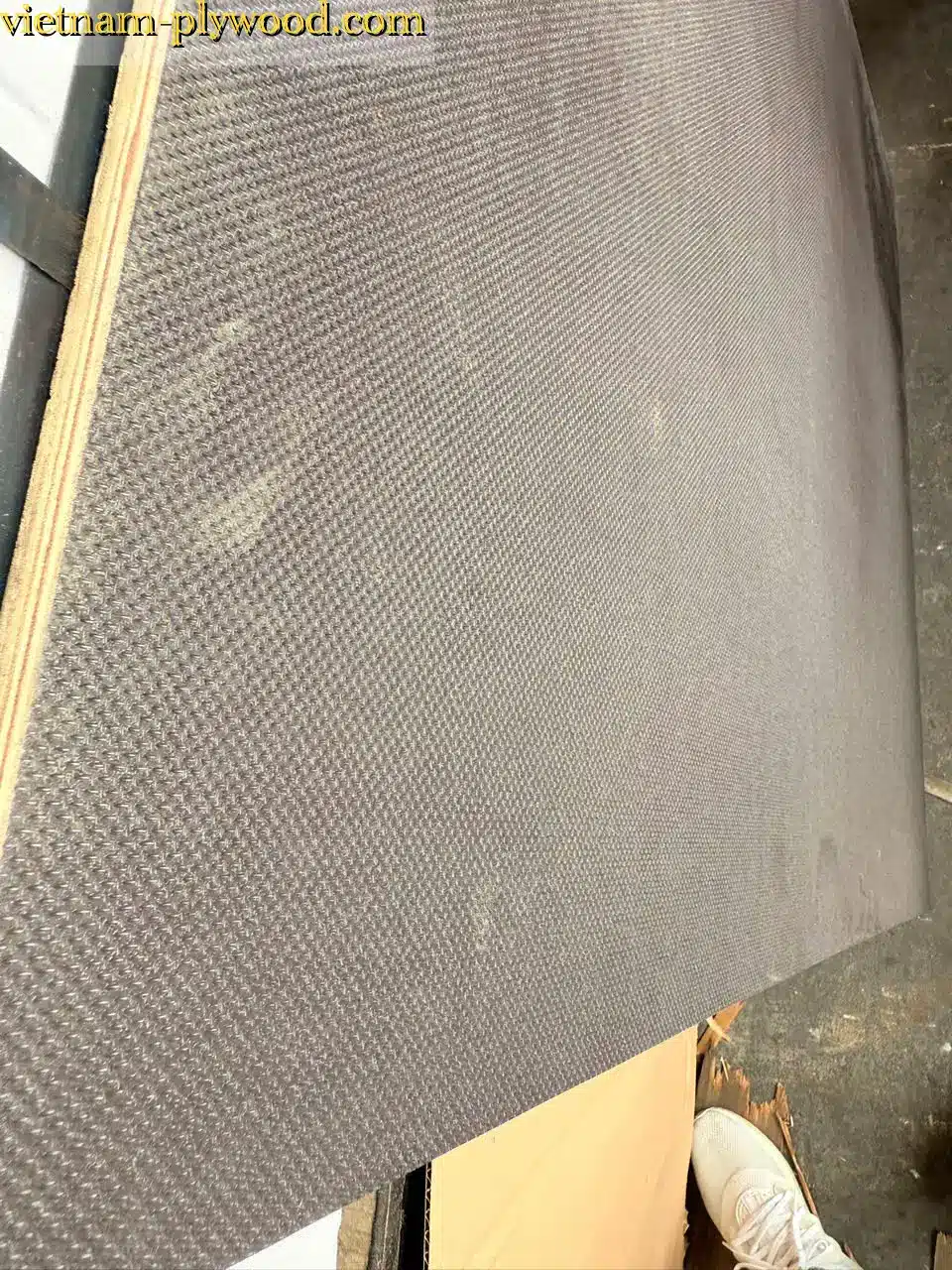

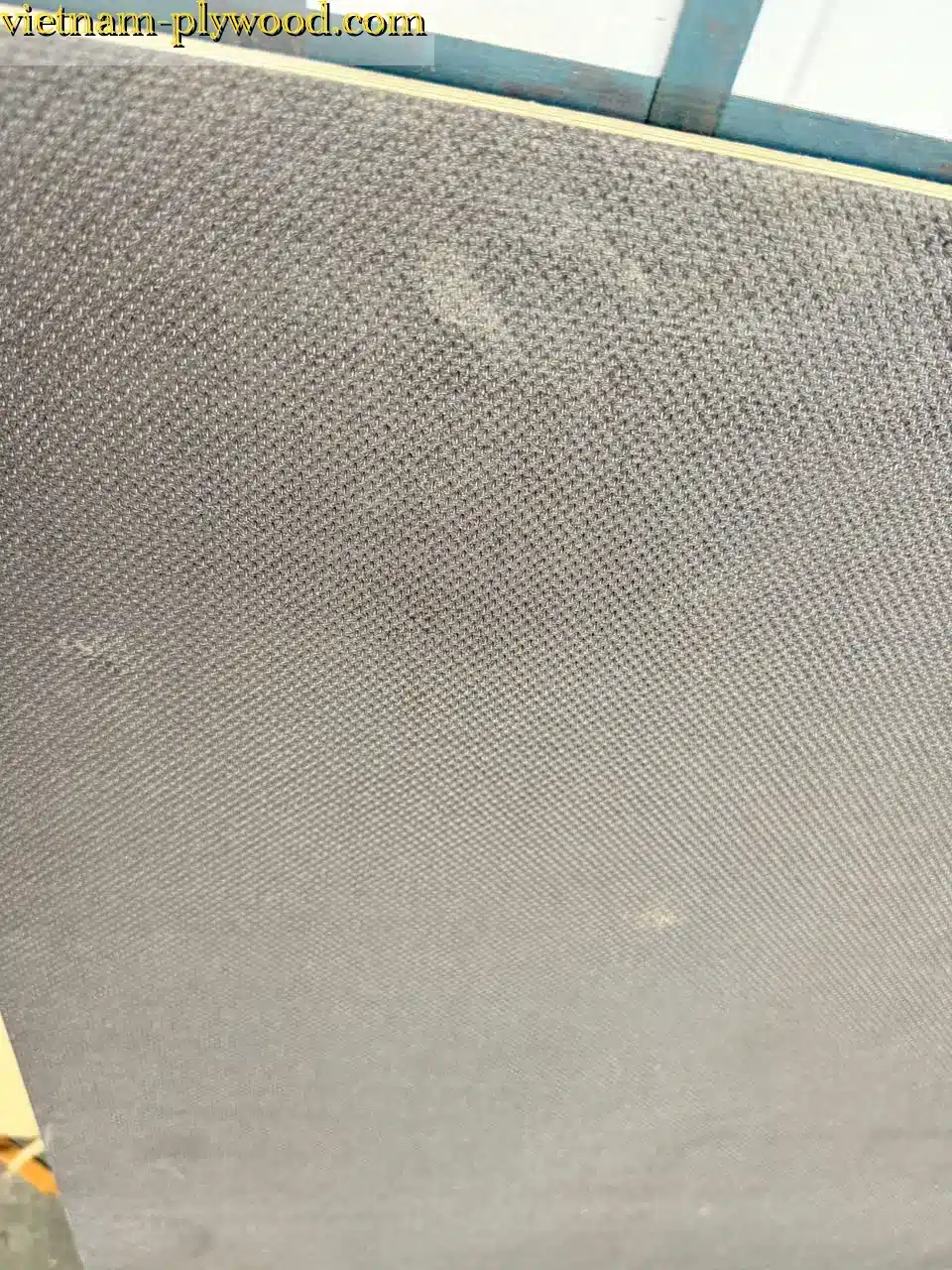

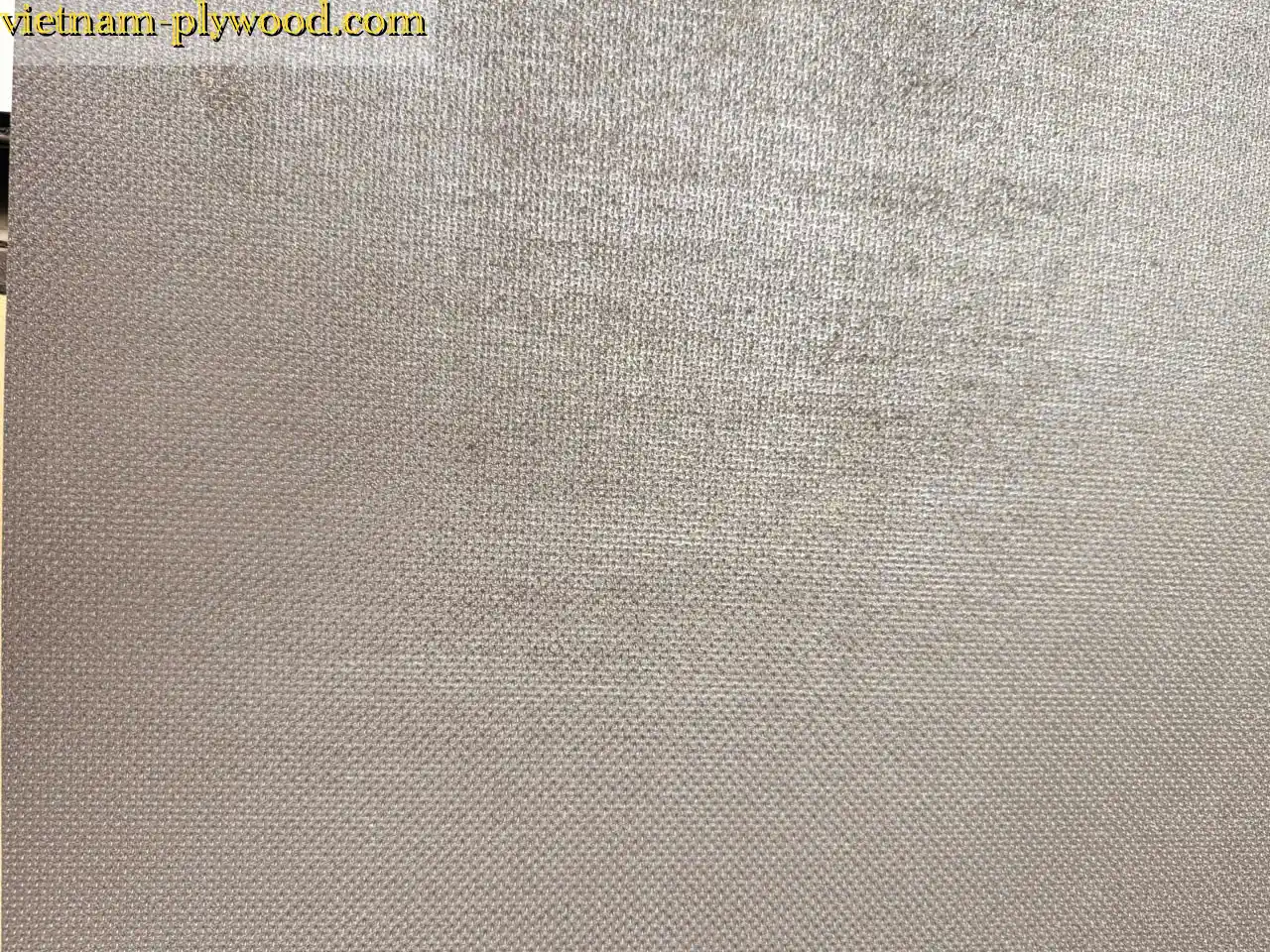

🔹 Rice Grain Pattern

- Uniform micro-texture

- Easier cleaning and maintenance

- Balanced grip with refined appearance

- Preferred for:

- Logistics centers

- Industrial walkways

- Reusable flooring systems

💡 Key point:

Both surface types deliver comparable anti-slip performance and durability. Choice depends on usage environment, not price — a strategic advantage for European buyers managing multiple projects.

🧪 Film Lamination Process – Not Just Pressed, Engineered

At HCPLY – Vietnam Plywood, film lamination is tightly controlled:

- Accurate temperature & pressure during hot press

- Resin flow synchronized with glue system (phenolic or melamine)

- Strong chemical bonding between film and face veneer

- No bubbling, peeling, or premature wear

This process ensures the anti-slip film becomes an integral structural layer, not a superficial coating.

🏗️ Why European Buyers Trust HCPLY – Vietnam Plywood

- ✔️ Stable friction performance over time

- ✔️ Consistent film quality across large volumes

- ✔️ Compatibility with phenolic & melamine glue systems

- ✔️ Full compliance with CE, CARB P2, FSC, EUDR, EUTR

As a manufacturer, supplier, and exporter operating at industrial scale, HCPLY – Vietnam Plywood delivers anti-slip plywood Vietnam that meets European safety expectations without cost inflation or performance compromise.

➡️ In the next section, we will connect surface performance with core + glue interaction, explaining how film choice works together with phenolic or melamine systems to define real-world lifespan and total cost efficiency.

🟦 05. European Standards & Certifications – Built for Compliance, Not Claims

For European buyers, anti-slip plywood is not accepted based on promises — it is approved based on compliance. As a leading manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood designs anti-slip plywood Vietnam from the factory level to meet and exceed European regulatory and technical standards required for construction, transport, and industrial flooring applications.

This is not post-production certification.

This is compliance engineered into the manufacturing process.

🏛️ Mandatory Standards for the European Market

Anti-slip plywood manufactured by HCPLY – Vietnam Plywood is produced in accordance with the most demanding European and international requirements:

- 🟢 CARB P2 / TSCA Title VI – ultra-low formaldehyde emission

- 🟢 CE Marking – structural plywood conformity for Europe

- 🟢 FSC® Certification – responsible and traceable wood sourcing

- 🟢 EUTR Compliance – legal timber due diligence

- 🟢 EUDR Ready – full supply chain transparency for EU deforestation regulation

Each standard is supported by verifiable documentation, factory audit trails, and shipment-level consistency — not generic certificates reused across products.

🧪 Compliance Starts Inside the Factory

At HCPLY – Vietnam Plywood, compliance is controlled through manufacturing discipline:

- ✔️ Certified veneer sourcing & species segregation

- ✔️ Kiln-dried core veneers (mandatory for phenolic systems)

- ✔️ Glue formulation matched to emission & durability targets

- ✔️ Controlled hot-press cycles (pressure, temperature, time)

- ✔️ Batch-level internal quality control before packing

This ensures that anti-slip plywood Europe buyers receive panels that pass real inspection, not just paperwork checks.

🚛 Approved for European Applications

Because compliance is built-in, anti-slip plywood Vietnam from HCPLY – Vietnam Plywood is widely accepted for:

- Truck & trailer flooring

- Scaffolding decks

- Logistics center walkways

- Industrial platforms

- Construction safety surfaces

European buyers choose HCPLY not only for performance and price — but because non-compliance risk is eliminated at the source.

🧠 Why European Importers Trust HCPLY – Vietnam Plywood

- 🏭 Manufacturer, not trader – full process control

- 📄 Transparent certification matched to each product spec

- 🌍 Export experience across EU markets

- ⚖️ Stable compliance even as EU regulations evolve

HCPLY – Vietnam Plywood is not adapting to European standards after production.

We manufacture for Europe from day one.

➡️ In the next section, we will analyze thickness, panel construction, and load-bearing configurations, and explain how European buyers select the right anti-slip plywood structure for each application.

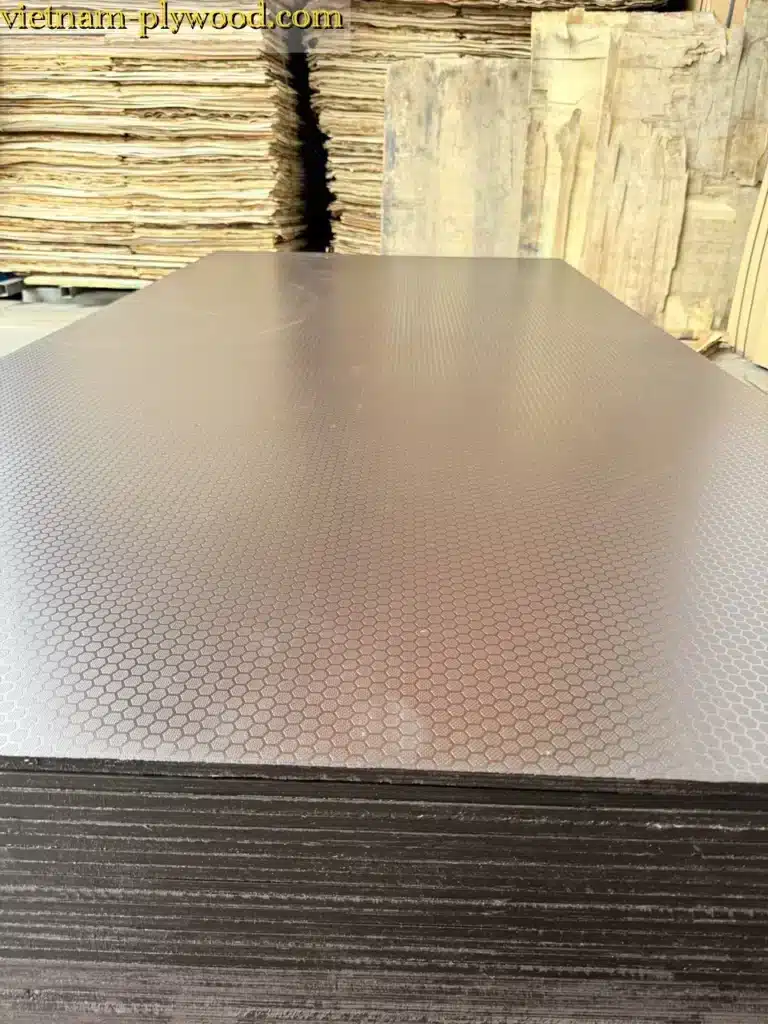

🟦 06. Thickness, Load Capacity & Structural Configuration for Anti-Slip Plywood

For European buyers, thickness selection in anti-slip plywood Vietnam is not a matter of preference — it is a structural engineering decision directly tied to safety, load performance, and service life. As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood designs thickness and ply configuration based on real European usage scenarios, not generic catalog standards.

🔩 Common Thickness Options Supplied by HCPLY – Vietnam Plywood

Our export-grade anti-slip plywood is manufactured in multiple thicknesses to match different load requirements:

- 12 mm – Light-duty platforms, temporary walkways, interior logistics use

- 15 mm – Medium-duty truck flooring, scaffolding decks, reusable formwork floors

- 18 mm – Heavy-duty transport flooring, industrial platforms, high-traffic zones

- 21 mm – Maximum load-bearing applications, long-term outdoor or industrial use

Each thickness is engineered with optimized ply count, veneer orientation, and pressing pressure to ensure consistent performance across full container volumes.

🏗️ Load Capacity Depends on Core + Glue + Thickness (Not Thickness Alone)

At HCPLY – Vietnam Plywood, thickness is never engineered in isolation. Real load performance depends on the interaction of three factors:

- Core species (Acacia vs Eucalyptus)

- Glue system (Phenolic WBP vs Melamine)

- Panel thickness & ply structure

For example:

- A 15 mm eucalyptus core + phenolic glue panel can outperform an 18 mm acacia + melamine panel in compression resistance and long-term stability.

- A 12 mm acacia core + phenolic glue panel may be sufficient for short-term transport flooring but not for permanent industrial platforms.

This is why European buyers work directly with HCPLY – Vietnam Plywood — to receive engineered recommendations, not assumptions.

📐 Ply Structure & Veneer Orientation

To maximize strength and prevent deformation, HCPLY applies controlled ply layup principles:

- Cross-oriented veneers for balanced stress distribution

- Higher-density veneers placed near surface layers

- Strict thickness calibration after hot pressing

This results in:

- Reduced edge cracking

- Improved screw holding capacity

- Consistent flatness across large panel formats

⚙️ Engineered for European Safety Expectations

All thickness configurations supplied by HCPLY – Vietnam Plywood are tested internally for:

- Load-bearing behavior under repeated stress

- Resistance to bending and deflection

- Compatibility with AICA anti-slip film adhesion

European buyers choose HCPLY not because we offer “many thicknesses,” but because we engineer the right thickness for the right application, at scale, with stable export quality.

➡️ In the next section, we will analyze real-world applications by industry — truck flooring, scaffolding, logistics, and industrial platforms — and explain how European buyers select the optimal anti-slip plywood configuration for each use case.

🟦 07. Application Scenarios – Where Anti-Slip Plywood Performance Truly Matters

For European buyers, anti-slip plywood is never a “one-size-fits-all” product. Performance is defined by where and how the panel is used. As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood engineers anti-slip plywood Vietnam specifically for real European application scenarios, ensuring safety, durability, and cost efficiency at industrial scale.

🚚 Truck & Trailer Flooring

Anti-slip plywood is most critically used in truck bodies and trailer floors, where panels are exposed to:

- Constant dynamic loads

- Forklift traffic

- Moisture, oil, and dirt

- Repeated loading and unloading cycles

HCPLY – Vietnam Plywood supplies:

- Acacia core + phenolic glue for cost-optimized fleets

- Eucalyptus core + phenolic glue for heavy-duty, long-life transport

✔️ Stable grip under wet conditions

✔️ No film peeling or edge delamination

✔️ Proven performance across European logistics fleets

🏗️ Scaffolding & Construction Platforms

Safety on construction sites is non-negotiable. European contractors rely on anti-slip plywood for scaffolding decks and temporary platforms where human safety is directly involved.

Our engineered solution includes:

- AICA anti-slip film 220 g/m² (Hexa or Rice Grain)

- Phenolic glue with kiln-dried core veneers

- Controlled ply orientation for load balance

✔️ High friction coefficient

✔️ Resistance to rain and jobsite moisture

✔️ Reliable performance over multiple reuse cycles

🏭 Industrial & Logistics Flooring

In warehouses, logistics centers, and industrial walkways, anti-slip plywood must combine grip, durability, and cleanability.

HCPLY – Vietnam Plywood anti-slip panels are widely used for:

- Indoor logistics platforms

- Industrial walkways

- Temporary factory flooring systems

Recommended configuration:

- Acacia or eucalyptus core (depending on load)

- Melamine glue for controlled environments

- Rice grain anti-slip pattern for easier maintenance

✔️ Balanced grip without aggressive surface wear

✔️ Stable panel geometry over time

✔️ Cost-efficient for large-area coverage

🛠️ Reusable & Modular Flooring Systems

European buyers increasingly demand reusable flooring solutions that reduce total project cost.

Our anti-slip plywood Vietnam is designed for:

- Modular floor panels

- Temporary event platforms

- Reusable industrial decking

✔️ High wear resistance from AICA film

✔️ Strong bonding for repeated assembly

✔️ Factory-direct consistency across large volumes

🧠 Engineered for Application – Not Guesswork

Unlike trading suppliers, HCPLY – Vietnam Plywood does not sell “anti-slip plywood” generically.

Each application is evaluated based on:

- Load intensity

- Exposure conditions

- Required service life

- Budget optimization

This application-driven manufacturing approach is why European buyers trust HCPLY – Vietnam Plywood as a long-term manufacturer, supplier, and exporter — delivering anti-slip plywood Vietnam that performs exactly where it matters most.

➡️ In the next section, we will analyze cost structure, pricing logic, and how European buyers optimize total project cost without compromising safety or compliance.

🟦 08. Pricing Structure & Cost Logic – How European Buyers Optimize Total Cost

For European importers, the true value of anti-slip plywood Vietnam is not defined by unit price alone, but by how pricing aligns with performance, lifespan, and compliance risk. As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood builds transparent pricing models that allow buyers to optimize total cost of ownership, not just FOB numbers.

💰 Base Price Levels – Clear, Factory-Direct

Our export pricing for anti-slip plywood is engineered around core species and glue systems:

- 🟢 From ~420 USD/CBM

- Acacia core

- Melamine glue

- AICA anti-slip film (220 g/m²)

- Ideal for cost-sensitive, controlled-environment applications

- 🔵 From ~490 USD/CBM

- Acacia or eucalyptus core

- Phenolic (WBP) glue

- Kiln-dried veneers (mandatory)

- Designed for heavy-duty, long-term European use

These prices are factory-direct, scalable for full-container volumes, and stable across long-term supply programs.

⚖️ Why Core Choice Impacts Price – and Value

- Acacia core

- Density: 550–600 kg/m³

- Lower raw material cost

- Excellent bonding efficiency

- Best cost-performance ratio for most European logistics and transport use

- Eucalyptus core

- Density: 650–750 kg/m³

- ~+30 USD/CBM compared to acacia

- Higher MOR/MOE, compression strength, and elasticity

- Preferred where maximum load and minimal deformation are required

💡 European buyers often select eucalyptus only where structural demand justifies the premium — not by default.

🧪 Glue System Cost Logic

- Melamine glue

- Saves 50–80 USD/CBM vs phenolic

- Suitable for indoor or semi-covered use

- Lower initial cost, shorter service life

- Phenolic glue (WBP)

- Higher production cost due to:

- Veneer kiln drying

- Longer pressing cycles

- Higher resin content

- Delivers superior waterproofing and reuse cycles

📌 Buyers focused on reuse count, durability, and liability reduction consistently choose phenolic systems despite higher FOB price.

📦 Price Stability at Export Scale

Unlike trading suppliers, HCPLY – Vietnam Plywood controls:

- Veneer sourcing & drying

- Glue formulation

- Film lamination

- Batch-level QC

This allows:

- Stable pricing across multiple shipments

- Consistent quality across full 40HC containers

- Reduced risk of claims, rejection, or downtime

🧠 Smart Buying Strategy Used by European Importers

Most experienced European buyers work with HCPLY to:

- Use melamine + acacia for short-term or indoor projects

- Use phenolic + eucalyptus for safety-critical or long-term applications

- Mix specifications across projects to optimize annual purchasing budgets

This flexibility is only possible when working directly with a manufacturer-exporter, not intermediaries.

➡️ In the next section, we will examine delivery reliability, lead time, and export logistics — and explain why supply stability from Vietnam has become a decisive advantage for European buyers.

🟦 09. Delivery, Lead Time & Export Reliability – Built for European Supply Chains

For European buyers, anti-slip plywood is not only about technical performance — it is about delivery reliability at scale. Delays, inconsistent loading, or unstable supply chains directly impact transport fleets, construction schedules, and contractual penalties.

As a large-scale manufacturer, supplier, and exporter, HCPLY – Vietnam Plywood structures anti-slip plywood Vietnam production around export continuity, not spot orders.

🚢 Stable Lead Time from Vietnam

HCPLY operates with:

- Dedicated production lines for film faced anti-slip plywood

- Pre-secured raw material sources (acacia & eucalyptus veneer)

- In-house veneer drying capacity (mandatory for phenolic glue)

Typical lead time:

- 🟢 15–20 days production

- 🟢 FOB Hai Phong / Cai Lan ports

- 🟢 Full-container scale (20GP / 40HC / 45HC)

📦 Export-Oriented Packing & Loading

Anti-slip plywood from HCPLY – Vietnam Plywood is packed for long-distance European transport:

- Calibrated pallet height for container optimization

- Moisture-protected edge & corner control

- Batch-marked pallets for traceability

- Stable weight distribution for truck flooring buyers

This eliminates common issues European importers face with:

❌ Broken pallets

❌ Film damage during transit

❌ Mixed specifications in one container

🌍 Why European Buyers Shift to Vietnam

Compared to unstable origins, Vietnam offers:

- No anti-dumping tax risk

- Predictable export procedures

- Shorter lead times vs Eastern Europe

- Strong compliance with EU documentation

HCPLY – Vietnam Plywood is selected not just as a supplier — but as a long-term manufacturing partner capable of supporting recurring European demand programs.

➡️ Next, we will summarize how all performance, compliance, pricing, and logistics factors come together — and why European buyers increasingly standardize anti-slip plywood sourcing from HCPLY – Vietnam Plywood.

🟦 10. Final Summary & Why European Buyers Choose HCPLY – Vietnam Plywood

Anti-slip plywood Vietnam has become the preferred solution for European transport, construction, and industrial flooring — not by chance, but by engineering, process control, and export discipline.

🔑 What Defines HCPLY Anti-Slip Plywood

When European buyers choose HCPLY – Vietnam Plywood, they secure:

- 🏭 Manufacturer-level control – not trading risk

- 🪵 Engineered core options – Acacia (cost-efficient) or Eucalyptus (heavy-duty)

- 🧪 Phenolic or Melamine glue systems – matched to real usage

- 🧱 AICA anti-slip film – Hexa or Rice Grain, 220 g/m²

- 📄 Full compliance – CARB P2, CE, FSC, EUTR, EUDR

- 🚢 Export reliability – stable lead time, scalable volume

💰 Transparent & Competitive Pricing

- From ~420 USD/CBM – Acacia core + Melamine glue

- From ~490 USD/CBM – Acacia/Eucalyptus + Phenolic glue

All prices are factory-direct, designed for long-term European supply contracts — not short-term spot deals.

🎯 Who This Product Is For

Anti-slip plywood Vietnam by HCPLY – Vietnam Plywood is ideal for:

- European truck body manufacturers

- Logistics & transport operators

- Construction and scaffolding companies

- Industrial flooring system integrators

- Buyers replacing higher-cost or unstable origins

🤝 Final Commitment from HCPLY

We do not sell anti-slip plywood as a commodity.

We manufacture it as a safety-critical, performance-driven product, engineered for Europe — with the scale, discipline, and transparency that European buyers demand.

📩 Contact HCPLY – Vietnam Plywood today to receive:

- Technical specification matching

- Application-based recommendations

- Factory-direct quotation

- Samples for evaluation

Anti-slip plywood Vietnam — engineered, certified, and exported with confidence.

🔗 Explore More Export-Grade Plywood Solutions from HCPLY – Vietnam Plywood

As a leading plywood manufacturer, supplier, and exporter in Vietnam, HCPLY – Vietnam Plywood offers a complete portfolio of export-grade plywood products trusted by European buyers for quality consistency, compliance, and competitive pricing.

Each product below is engineered at factory scale, certified for international markets, and supplied with stable lead times.

🪵 Interior & Furniture Plywood

👉 Birch Plywood Vietnam

Premium birch-faced plywood for European interiors – white core options, CARB P2 & CE compliant.

👉 Poplar Plywood Vietnam

Lightweight, clean-surface plywood ideal for furniture, cabinetry, and decorative panels.

👉 EV Plywood Vietnam

Engineered veneer plywood with consistent appearance and cost efficiency – a smart alternative to natural birch.

🏗️ Construction & Industrial Plywood

👉 Film Faced Plywood Vietnam

High-performance shuttering plywood for construction, supplied with phenolic glue and durable film overlays.

👉 Anti-Slip Plywood Vietnam

Non-slip plywood for truck flooring, scaffolding, and industrial platforms – AICA film, phenolic or melamine glue.

📦 Packaging & Structural Panels

👉 Packing Plywood Vietnam

Cost-optimized plywood for export packaging, crates, and pallets – stable quality at scale.

👉 Matt Plywood Vietnam

Unfaced plywood designed for lamination and further finishing – ideal for OEM furniture factories.

🌳 Core Materials & Manufacturing Control

👉 Core Veneer Vietnam

Acacia, eucalyptus, and white core veneers produced in-house for full quality and cost control.

🤝 One Manufacturer – Multiple Solutions

By sourcing directly from HCPLY – Vietnam Plywood, European buyers secure:

- 🏭 Factory-direct supply (no trading risk)

- 📄 Full compliance: CARB P2, CE, FSC, EUTR, EUDR

- 🚢 Stable export capacity for long-term programs

- 💰 Competitive pricing with consistent quality

📩 Contact HCPLY – Vietnam Plywood today to build a reliable, scalable plywood supply chain for Europe.